by Danke Mold | Dec 1, 2022 | Blog

The world today is focussing everything that is quite disposable. This has resulted in a huge enhancement and enhancement in the plastic injection moulding technology by and large. But, what are the benefits that you would stand to gain with the plastic injection...

by Danke Mold | Nov 25, 2022 | Blog

Plastic injection molding as a manufacturing process has been growing consistently. The resin used in the plastic injection molding process does have an impact on the quality of the final product. Which materials are you expected to use for the best product quality?...

by Danke Mold | Nov 16, 2022 | Blog

The concept of the plastic injection molding has been quite impressive and efficient and has grown consistently over the past few years. It is quite popularly used in the case of mass manufacturing requirements. The concept of plastic injection molding has been widely...

by Danke Mold | Jan 24, 2019 | Blog, Rapid Prototyping

Some practical notes about Rapid Prototyping-Sectioning When we running rapid prototype projects, which I mean includes CNC machining, SLA and vacuum casting projects, there’s various of “rules” that we should know. These “rules” are actually indications to help us to...

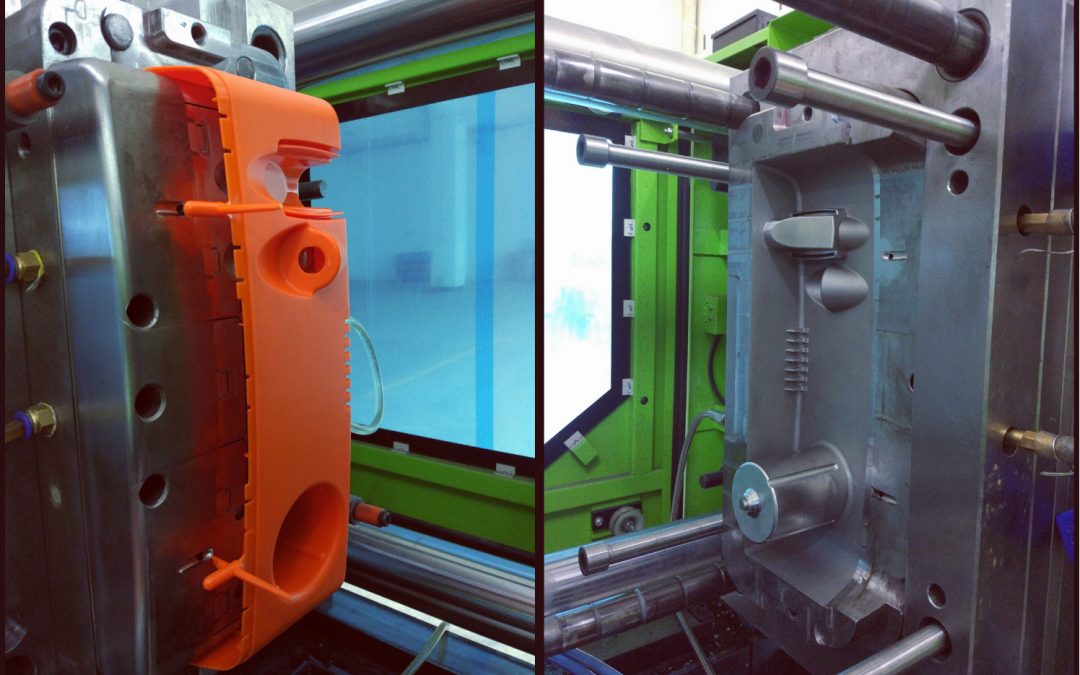

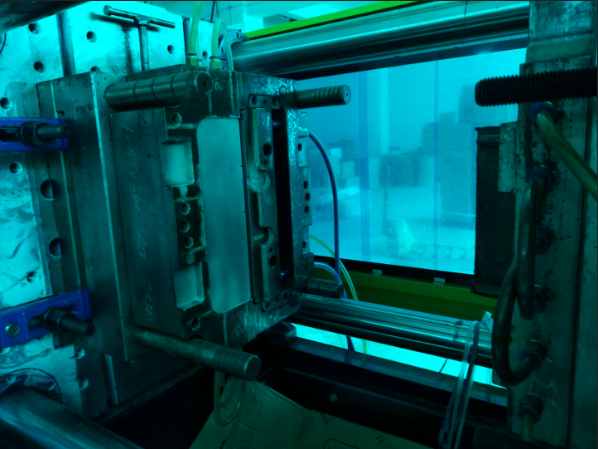

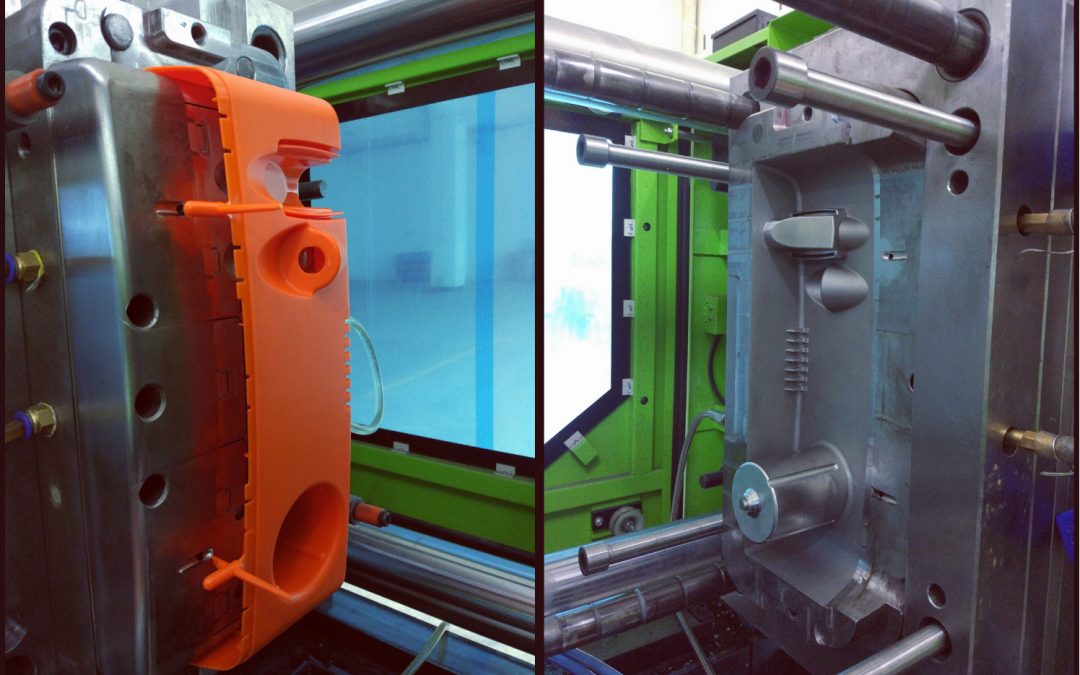

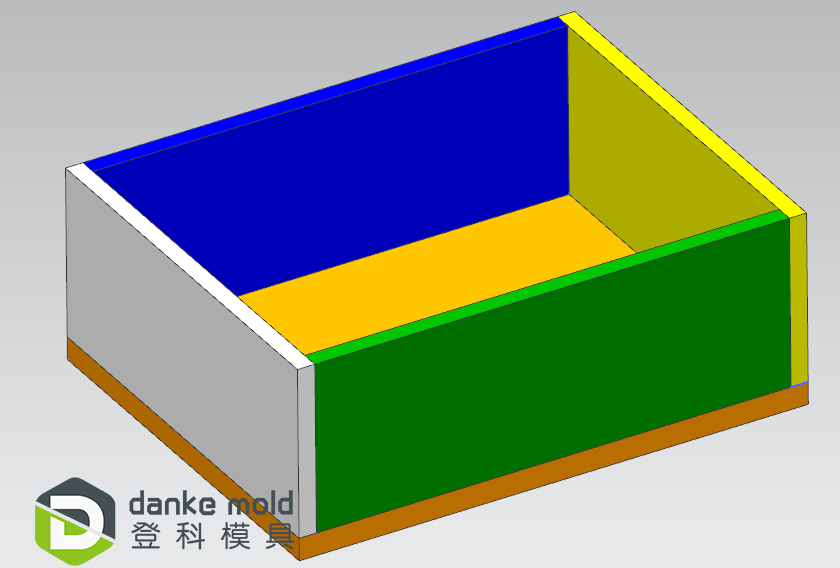

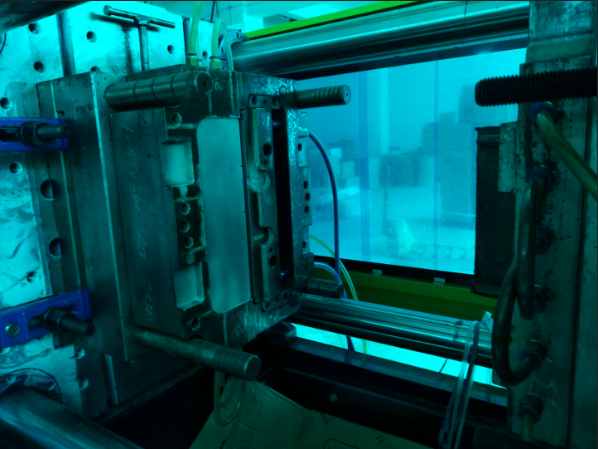

by Danke Mold | Jan 18, 2019 | Blog, Rapid tooling & Injection molding

What’s difference between Rapid Tooling and Production Mold From application difference of plastic injection molds, we can roughly separate them into rapid tooling, and production injection mold. Rapid tooling is mainly for early stage of product...