Professional Rapid Tooling

& Custom Injection Molding

☼ Free DFM Feedback With Your Quote

☼ No Minimum Order Quantities Request

☼ T1 Samples As Quick As 14 Days

☼ Prototyping & Production Mold-making

The Better Way You Make Custom Parts

From Prototype Tooling to Custom Injection Molding, Danke Mold team have been in this filed for over 12 years, deeply understand customers exact demands and how to fulfill their requirements. Our comprehensive manufacturing services help our clients save money, shorten lead time, launch their products to market earlier, and increase their overall product quality. This is why we’re one of the best injection mold manufacturers of choice for businesses across China. As a reliable plastic injection molding company, our rich experience, solid engineering support, advanced requirements, strict quality control and professional & efficient communication will accelerate your product development.

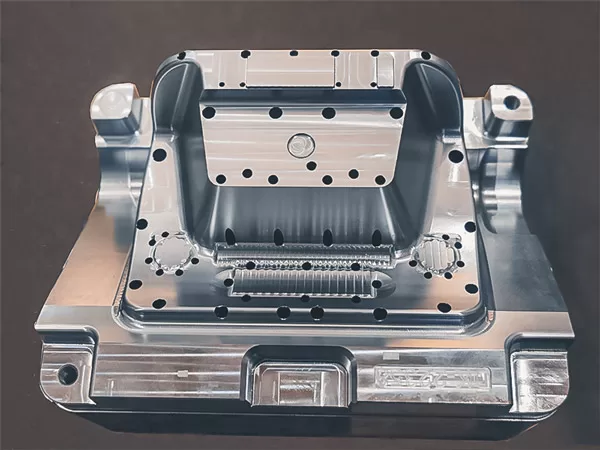

Rapid Tooling

- Flexible Tool Design

- More Cost Effective

- As Fast As 14 Days

- Ideal For Bridge Production

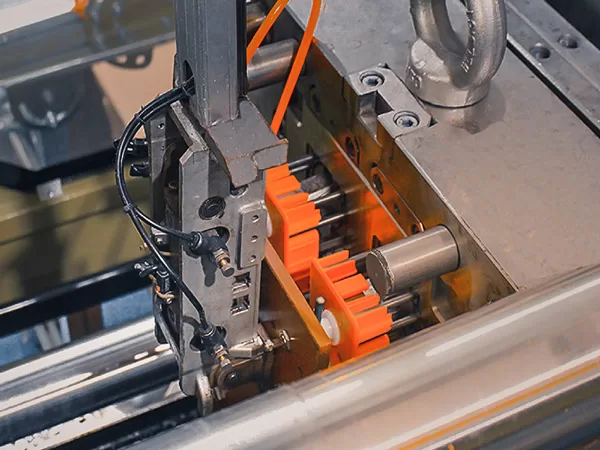

Injection Molding

- No MOQ Requirement

- Dozens Of Material

- Multiple Surface Finishes

- Over Molding & Insert Molding

Compression Molding

- Silicone Rubber Parts

- Polyurethane Parts

- No MOQ request

- Cost effective tooling

Rapid Prototyping

- Rapid CNC Machining

- Urethane Vacuum Casting

- 3D Printing (SLA/SLS)

- Sheet Metal Forming

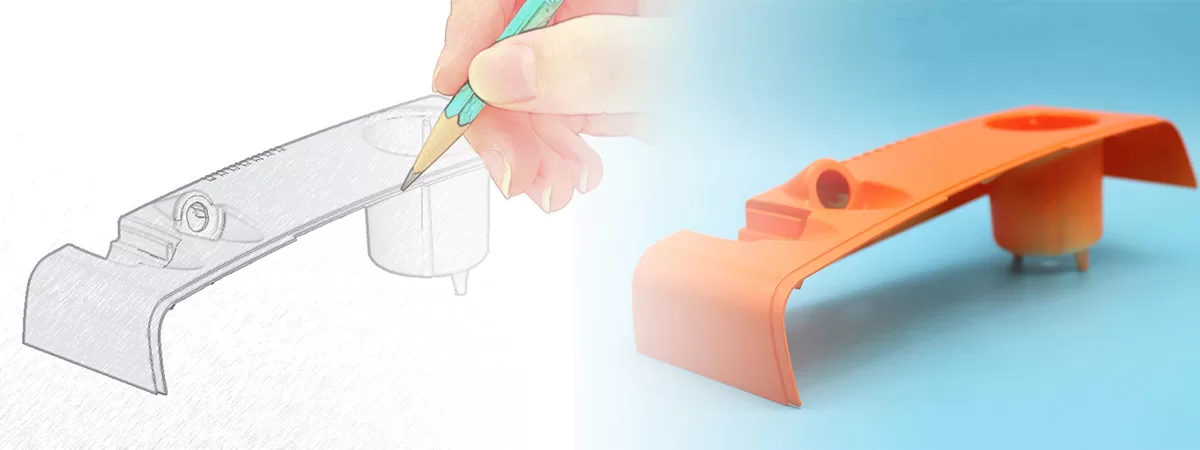

From Rapid Prototyping

to Custom Injection Molding

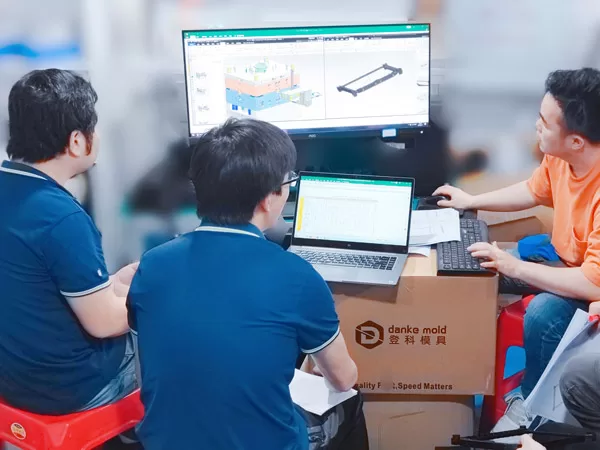

Danke Mold provides one-stop manufacturing services, and strong engineering support can help you to accomplish your product development and volume production. We will work with you to understand the requirement of your project, then develop a precise plastic injection mold design according to your specifications. Our versatile engineers handle all complexities involved in the mold production process.

Check out more videos and reels on our Youtube channel.

Quick Instant Quote

Please provide your drawing files and tell us your requirement about material, quantity and surface finishes, etc.

Case Study:

Housing Parts of Electric Vehicle Charger

Within the flourishing market of Electric Vehicles, our client was looking to design their new generation home charging Together we helped them to develop their first new product of their future charging station family.

In this project, we helped the customer to make the injection mold and do produces Mid/low volume for the housing parts and the LED lens.

Mold Type: Rapid Tooling (Custom Mold Base, Manual Inserts)

Material: PC+ABS & PC.

Surface finish: Fine Textured/ SPI-B2

▶ Read More

Why Choose Danke Mold As Your Manufacturing Partner

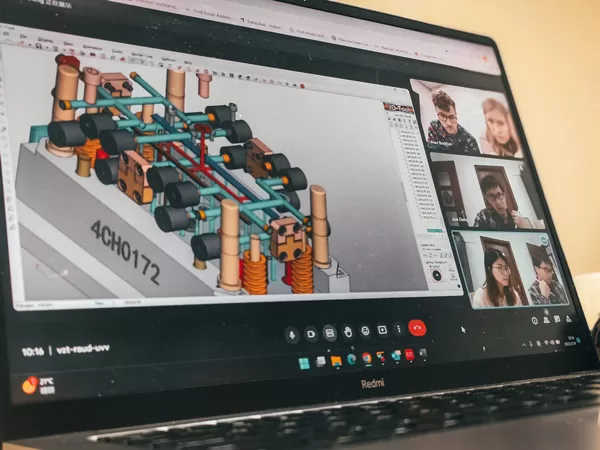

Excellent Communication

- Swift response within 12 hours

- Deeply understand customers’ requirement

- Available at video meeting, skype, phone call

- Sample Images before shipment

- Weekly project update

Solid Engineering Support

- Free molding DFM analysis

- Material suggestions

- Muti material trials available

- Rich experience engineers for project management

- Risk remind before tooling start

- Positive & feasible solutions when an issue

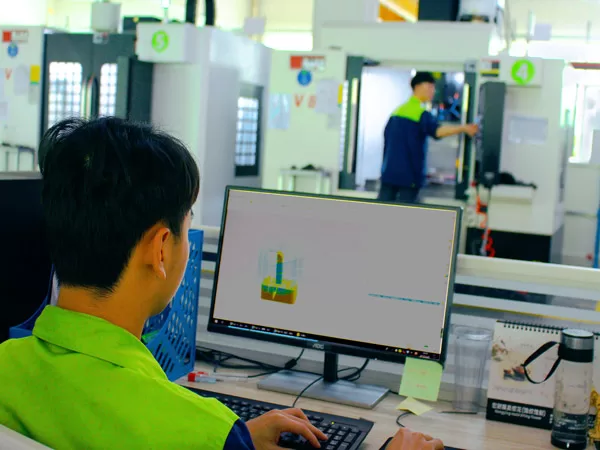

Strict Process Control

- Tooling & molding issues forecasted

- Final DFM review & Tool design review before mold making

- On site process check and control

- Injection Molding Parameters record

- No regrind material used

- SOP documents for production control

Strict Quality Control

- ISO 9001:2015 certified

- All material with CoC documents

- FAI reports for mold trial & production start

- Production on-site check with master sample & critical dimensions

- SIP document for quality control

- 100% cosmetic check

Aggressive Turn-around Time

- Days for rapid tooling

- Competitive tool making lead time

- Aggressive at tooling modification

- Swift at plastic injection molding production

- Always there to answer your questions or concerns

Flexible at Special Requirement

- No MOQ requirement

- Project accelerated available

- 3D scanning & prototype development

- Mechanical design for simple product

- Soft assembly & packaging

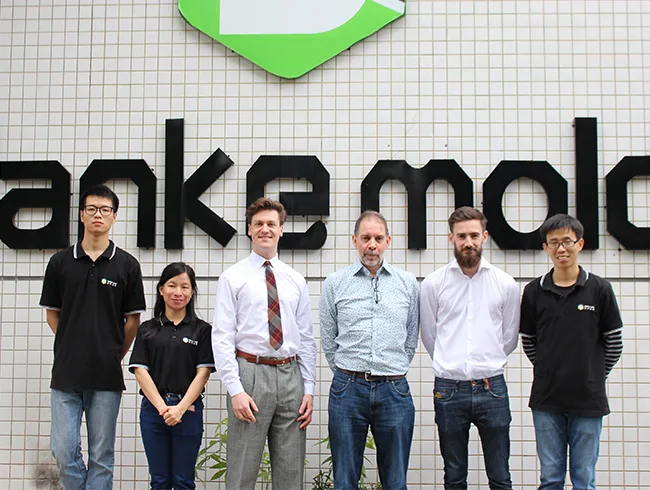

Our Team And Our Customers

How It Works : Plastic Injection Molding Services

From prototyping molding to mass production, we offer over 12 years of injection molding manufacturing expertise in every step of the process.

1. Project Info. Collection

2. Molding Quotation

3. Molding DFM Analysis

4. Tool Design

5. Mold Making

6. Mold Trial

7. Sample Submission

8. Sample Improvement

9. Samples Approval

10. Molding Production

11. Quality Check

12. Parts Shipment