Insert Molding Services

-

DFM Suggestions

-

No MOQ

Insert Injection Molding

As part of the injection molding service at Danke Mold, we provide Insert molding from low volume production to high volume injection molding production requirement. It not only provides an injection molding option to have a part more precisely & tidy, but also being more cost efficiency, as without 2nd operation by post assembly or heat staking. During all the plastic injection molding projects we went through, we have ever worked on many insert-molding projects, and got rich experiences from them. With our professional & rich experience, we will take your insert molding projects successfully into the market.

Capacity of Insert Moldings

Part Size:

No limitation. Generally, within 850*500*300mm (L*W*H)

General Plastic Injection Molding material for Insert Molding:

- ABS

- PC/ABS

- PP

- PA+GF

- POM

Material NOT suggested for Insert Molding:

- PC

- PMMA

- GPPS

Our concern would be at the material flow ability. This material with low material flow ability. The molding defect of crack or welding line would easily happen. If insert molding is strongly requested, we would pre-heat the inserts before injection molding production.

Thread Insert moldings:

- Brass thread inserts

- Stainless steel thread inserts

- Customer provided thread inserts preferred

Other Metal Insert Moldings:

- Custom metal inserts provided by customers;

- Custom metal inserts manufactured by Danke Mold.

However, we’ve been in the manufacturing industries and have worked with many customers for general product develop for more than 10 years. We have our technical insight and stable supply chain at the sub metal components.

Anyway, transparency and trust will be most important, especially at the beginning of business cooperation. We will truly let our customer know what we can do and what we can not do clearly. And provide true value to our customer at the product development.

DFM Suggestions at Insert Molding

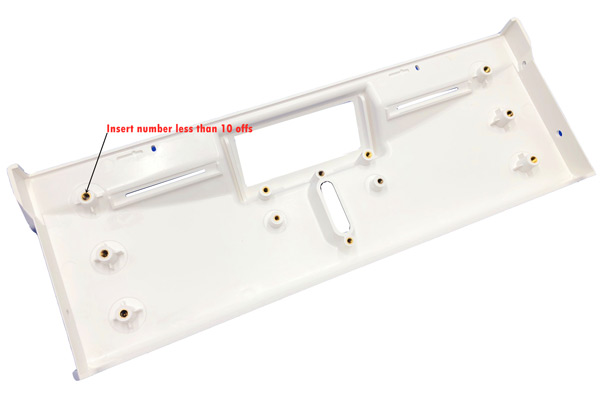

1. Reduce the thread Inserts number (prefer within 10 offs)

Our Consideration:

It’s for the cycle time concerns.

Unless for a mass volume molding production, at most of insert molding, the thread inserts will be placed into the injection molding tooling manually.

If too many thread inserts, the injection molding cycle time will be pretty long. The plastic molding material will stay in the barrel too long. The material will easily get over-heated and then cause high injection molding production scraps.

It’s especially for PC and PMMA material. Thåey are heat sensitive material, and will get over-heated easily.

2. Minimum the Length of the Thread Inserts without effect the function.

Our Consideration:

It is for the cost concern.

The longer the thread insert is, the higher cost the inserts will be.

Mostly, the functional length should be less than 10mm. Seldom of them will be out of 15mm.

For some big enclosures, the thread inserts maybe requested as 20-40mm long sometimes, for avoiding the thick material & molding surface shrinkage.

Our suggestions would be adjusting the mechanical design, shorten the boss, or shorten the inserts.

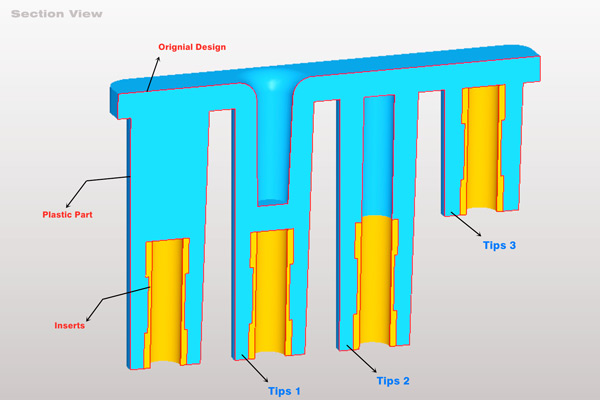

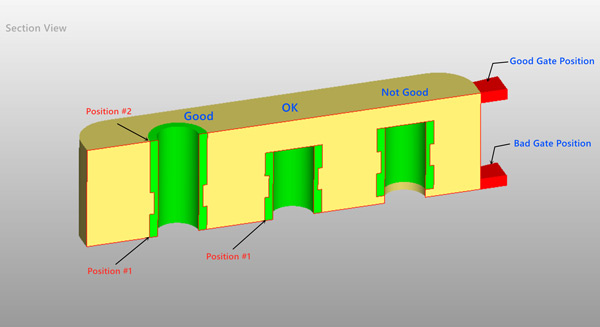

3. With Positioning of the Thread Inserts.

Our Consideration:

It is for the stable injection molding production.

The best is to have the both sides of the insert kissing off the tooling.

Or the least there is one side of the insert kissing of the tooling, while the material flow during the injection molding, is to warding this kissing-off surface.

To the manufacturer, the hole size of the inserts should be stable(+/-0.02mm), so that the thread inserts will be holding well on the tooling.

Aluminum Rapid Tooling Samples

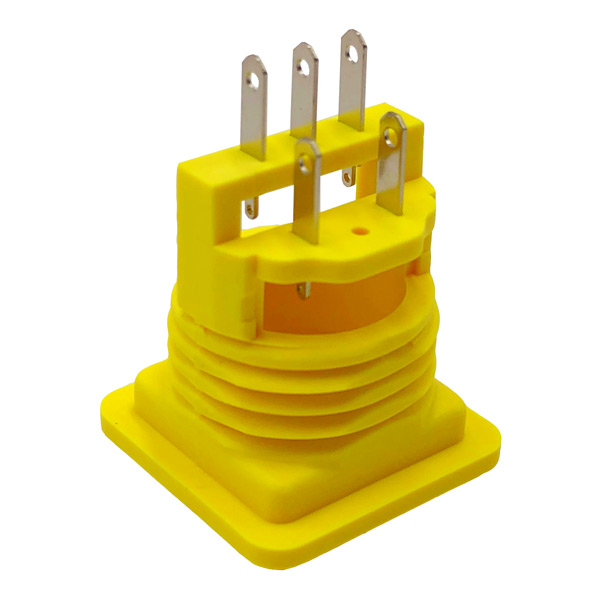

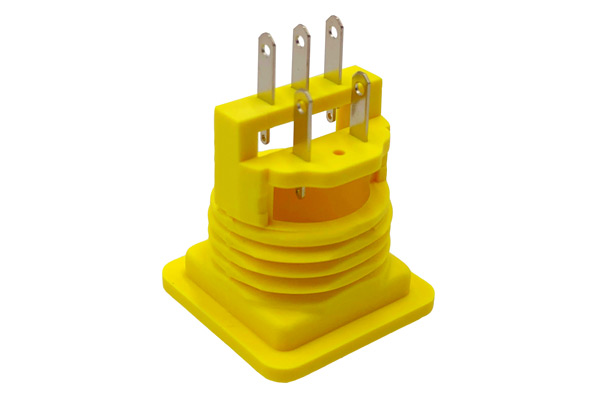

Project Description:Plug

Insert Details:Metal Pins

Insert Numbers:5 pcs

Injection Molding Material: PA66 +25%GF

Tooling Type: Production Injection Mold

T1 samples Lead Time:25 days

Batch Production Quantity: 2000pcs/batch

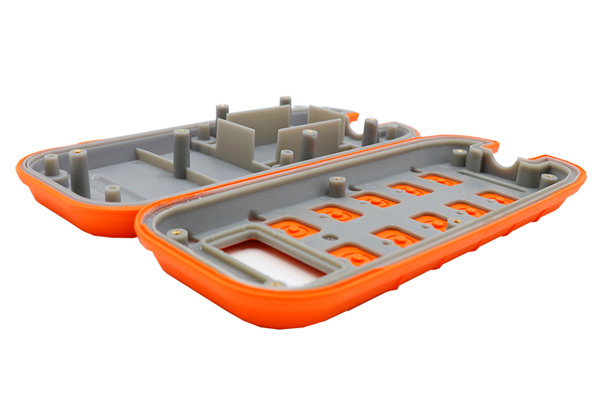

Project Description: Bicycle Lighting Case

Insert Details: Domestic M3 thread inserts

Insert Numbers: 4 pcs

Injection Molding Material: ASA

Tooling Type: Production Injection Mold

T1 samples Lead Time: 25 days

Batch Production Quantity: 1000 pcs/batch

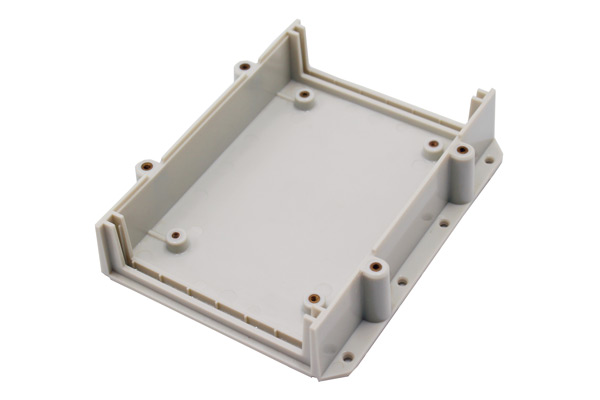

Project Description: Battery Frame

Insert Details: PEM M4 Inserts

Insert Numbers: 4pcs

Injection Molding Material: PA66+30%GF

Tooling Type: Production Injection Mold

T1 samples Lead Time: 28 days

Batch Production Quantity: 5000 pcs/batch

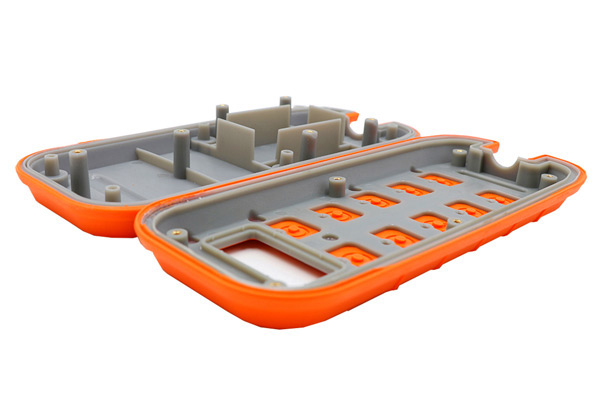

Project Description: Detecting Case

Insert Details: Domestic M3 & M2.5 Inserts

Insert Numbers: 8pcs

Injection Molding Material: PC/ABS

Tooling Type: Prototype Injection Mold

T1 samples Lead Time: 22 days

Batch Production Quantity: 500 pcs/batch

Project Description: Electronic Cap

Insert Details: Domestic M3 Insert

Insert Numbers: 1 pc

Injection Molding Material: POM

Tooling Type: Production Injection Mold

T1 samples Lead Time: 25 days

Batch Production Quantity: 2500 pcs/batch

Project Description: Controller Enclosure

Insert Details: Domestic M2.5 Inserts

Insert Numbers: 12 pcs

Injection Molding Material: PA66+15%GF

Tooling Type: Prototype Injection Mold

T1 samples Lead Time: 25 days

Batch Production Quantity: 100 pcs/batch