Over Molding Services

-

Custom Over-Molding

-

Material Suggestions

Over Molding

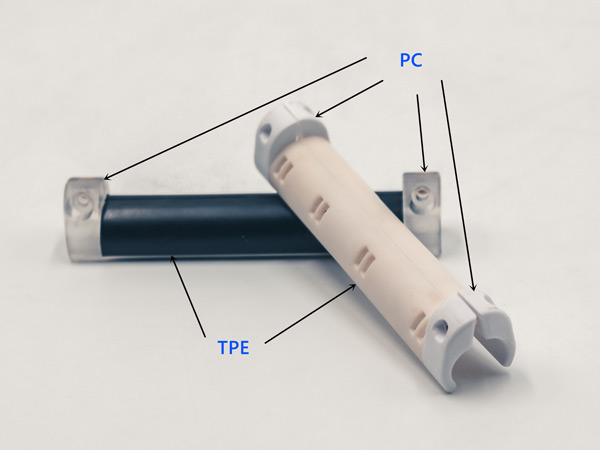

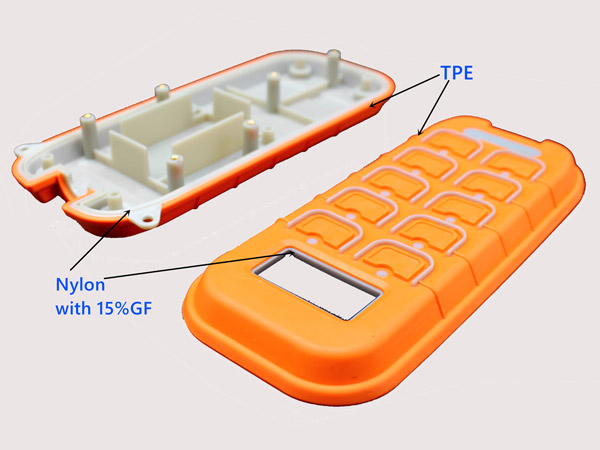

Over-molding is one of special plastic injection molding services. It bonds 2 plastic components by injection molding process. Instead of by post assembly, over-molding can provide more cosmetic & tidy plastic parts, and also being more production & cost efficiency.

Danke Mold provides over-molding service from prototyping molding to high-volume injection molding production. Our professional at over-molding material, over-molding mechanical structure, project management will guide you step by step to launch your product to market successfully

Capacity of Over Molding

Maximum Part Size: 550* 350*200mm (L*W*H)

Maximum Part Weight: 1.2kg

Maximum Depth: 100mm ( 200mm if parting cross the middle of the part)

Minimum wall thickness: 0.8mm

Minimum Order quantity: 50pcs

Over Molding Material Selections

For over-molding, the most important key is that both materials should be able to chemically bonding with each other.

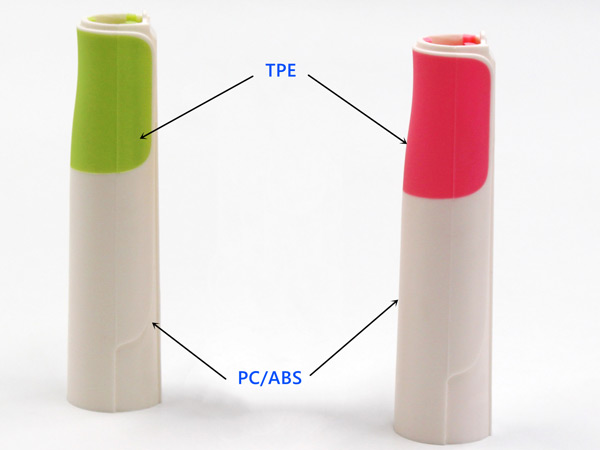

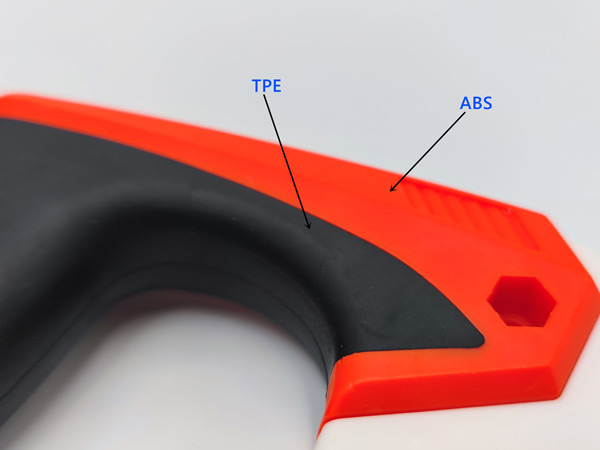

The most typical over molding is the soft handles that we used in our daily life. Following would be our over-molding material matches suggestions:

General material matches for over molding:

- PP+TPE

- ABS + TPE

- ABS+TPU

- PC/ABS+TPE

- PC/ABS + TPU

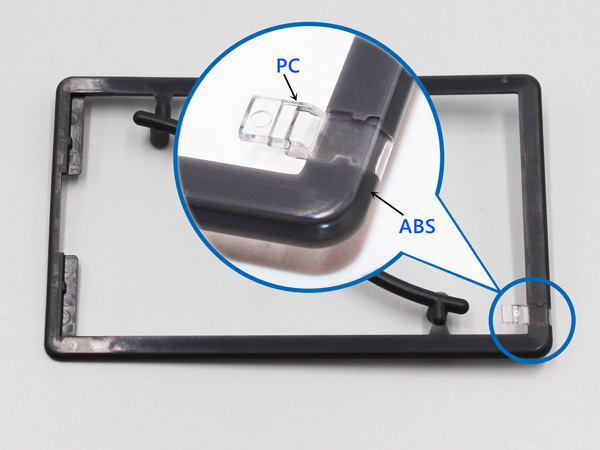

- PC + ABS

Front material to be injection molded first.

Not suggest for Over-molding:

- PA66 + TPE

- PA66 + TPU

- PA66/GF + TPE

- PA66/GF + TPU

If it’s requested for special functional requirement, the material must be specific grade for over-molding.

General grade would not be suitable.

Following would be some frequent used over-molding materials that with multi-colors.

At injection molding production with the same plastic material, a very important detail is that the setting of injection molding temperature should be slightly different for different component.

Our consideration is for avoiding/reducing the melting issue at the first component, as their melting temperature are the same.

General material matches for over molding with multi-colors:

- ABS

- PC/ABS

- PP

- PC

- HDPE

Mechanical Design for Over Molding

At over-molding, besides the material selections for chemically bonding, the other very import point is at the mechanical design.

A good mechanical design should be able to provide physical bonding, so that the product is more reliable from different respects.

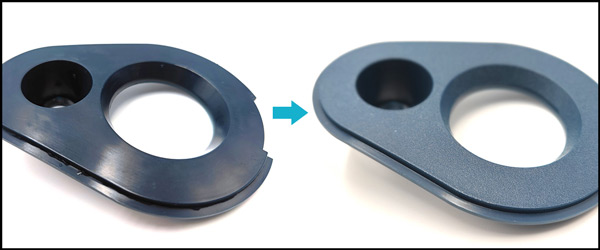

1. Have a rough textured surface finish.

Our Consideration:

Smooth, glossy, high glossy surface will not be good for bonding.

While a rough textured surface, can provide a bigger surface and better bonding.

For external surface, left at least 0.5 degrees draft for the bonding area.

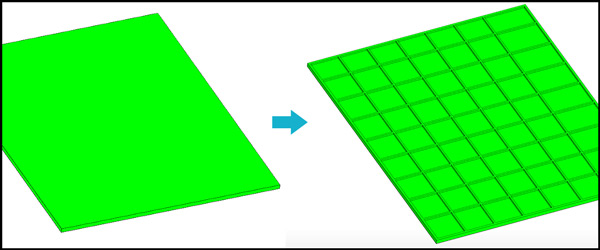

2. Increase the contact surface.

Our Consideration:

Increase some ribs;

Increase some gaps;

Both options will be fine. The chosen will be based on the mechanical design.

Either option is to increase the contact surface to provide bonding with each other better.

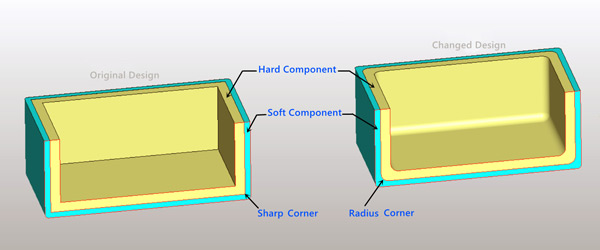

3. Avoid sharp corners.

Our Consideration:

At the sharp corner, because of very limited contact area for bonding & stress concentration, it will easily cause both components separated easily.

Would recommend a minimum radius of 0.5mm at the corner, for the surface transition.

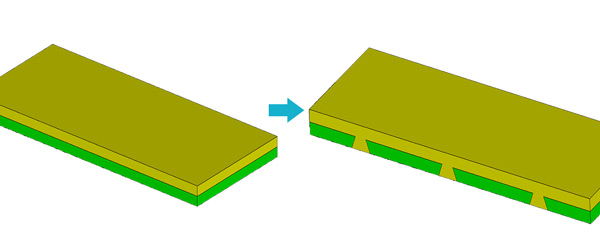

4. Undercut for better holding.

Our Consideration:

Even though chemical bonding is critical.

An undercut mechanical design can help the product being much more reliable.

With an external force, with the help of undercut, the mechanical bonding will suffer much less external force, so that the over-molding would be more reliable.

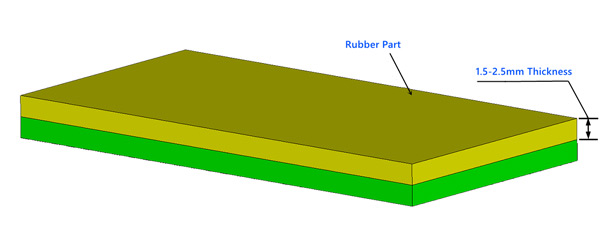

5. Even the wall thickness at 1.5-2.5mm.

Our Consideration:

Too thin will cause short shot or not sufficient soft-touch feeling.

Too thick will cause uneven shrinkage, flashes or unstable molding production.

So would recommend an even wall thickness as about 1.5-2.5mm for over-molding.

At thick areas, core out some material to achieve this thickness.

Or gradually transition for 2 different over-molding thickness.

Plastic Over Molding Projects

Are you looking working on an over-molding project? Maybe with low-volume requirement for market testing.

Have a contact with us now our swift response & professional over-molding services will be your reliable plastic injection molding partner.