by Danke Mold | Jul 11, 2025 | Rapid Prototyping

If you’re a startup looking to bring a product to market without committing to large quantities, low volume manufacturing offers a practical solution. This approach lets you produce smaller batches, reducing upfront costs while maintaining quality and flexibility. Low...

by Danke Mold | Jul 7, 2025 | Rapid Prototyping

Disposable medical device manufacturing involves producing single-use tools and instruments designed for safety and hygiene in healthcare. You rely on this manufacturing process to deliver sterile, high-quality devices efficiently, especially when volume manufacturing...

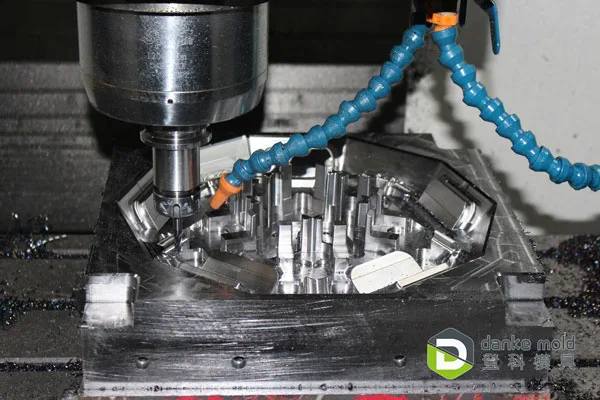

by Danke Mold | Jul 5, 2025 | Compression Molding

Compression molding creates strong, durable parts by applying heat and pressure to material placed directly in an open mold. This process excels at producing large, complex components with excellent surface finishes. How Compression Molding Achieves Superior Results...

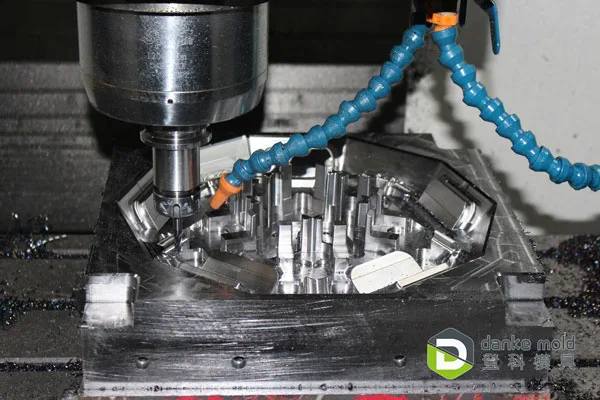

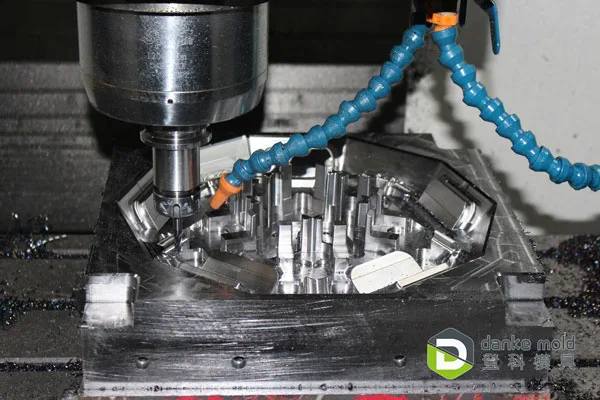

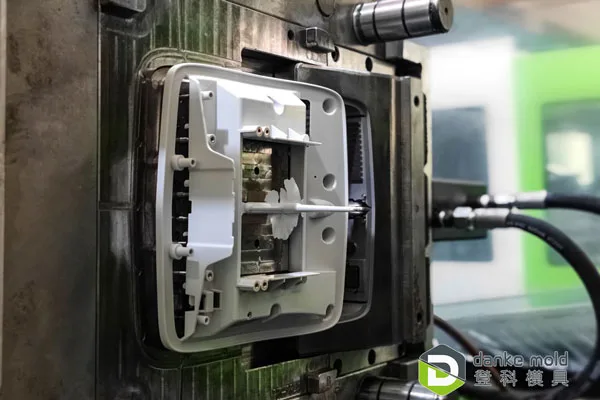

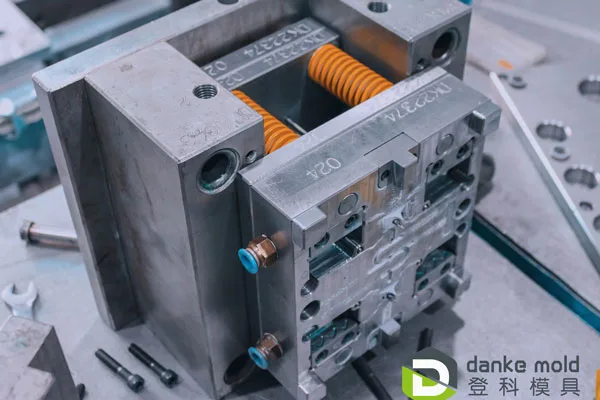

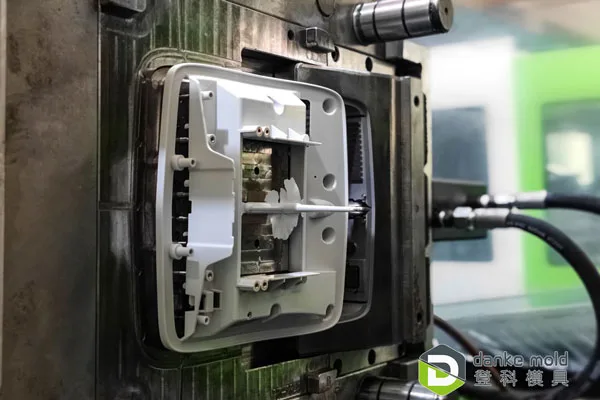

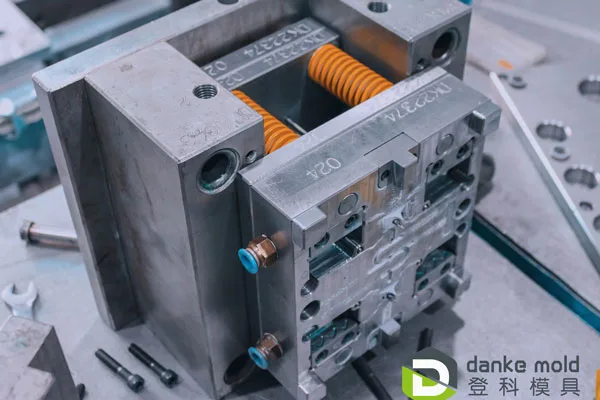

by Danke Mold | Jun 30, 2025 | Plastic Injection Molding

Plastic injection molding transforms raw plastic materials into finished products through a precise manufacturing process. This method enables manufacturers to produce complex shapes with consistent quality across thousands of units. Understanding the Plastic...

by Danke Mold | Jun 27, 2025 | Vacuum Casting

Liquid silicone rubber molding transforms how manufacturers create durable, flexible components across multiple industries. This advanced manufacturing process delivers exceptional precision and reliability for applications ranging from medical devices to automotive...