by Danke Mold | Apr 29, 2025 | Insert Molding

Contemporary manufacturing uses insert molding to make plastic, metal, and ceramic composites. Without compromising quality, it strengthens components, simplifies assembly, and decreases production costs. Insert molding ensures electronics, automotive, and medical...

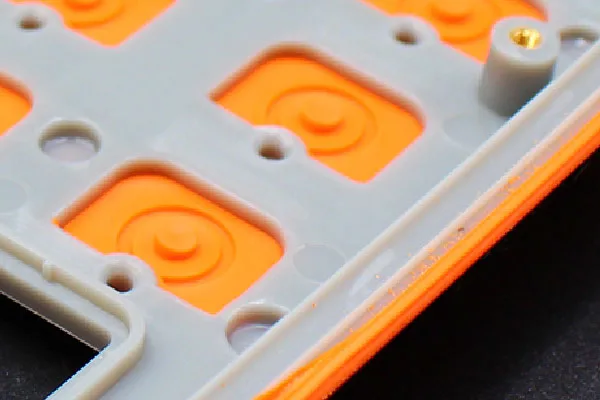

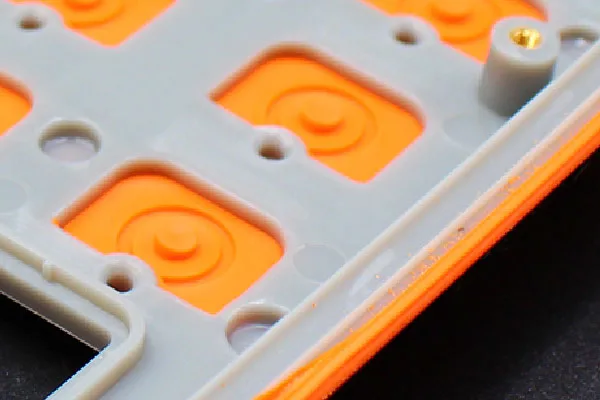

by Danke Mold | Apr 25, 2025 | Over Molding

Overmolding enables multi-material items to be made using modern injection molding techniques. Strong plastic or metal is covered with soft plastic or rubber. The seamless, multi-layered product improves grip, durability, and appearance. Consumer electronics,...

by Danke Mold | Apr 22, 2025 | Insert Molding

The economical and flexible insert molding technology combines plastic and metal components into a single item. Automotive, medical, electronics, and consumer goods sectors employ insert molding to strengthen, decrease assembly stages, and increase product longevity....

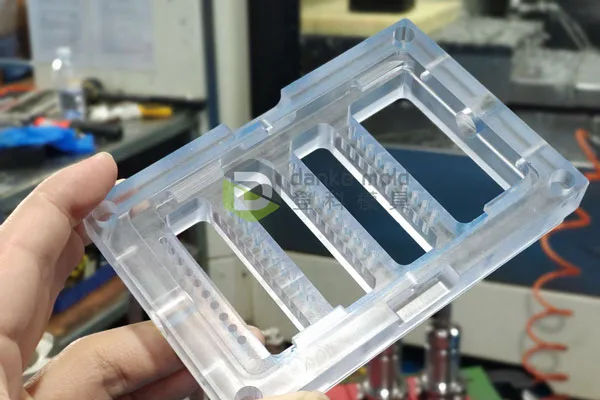

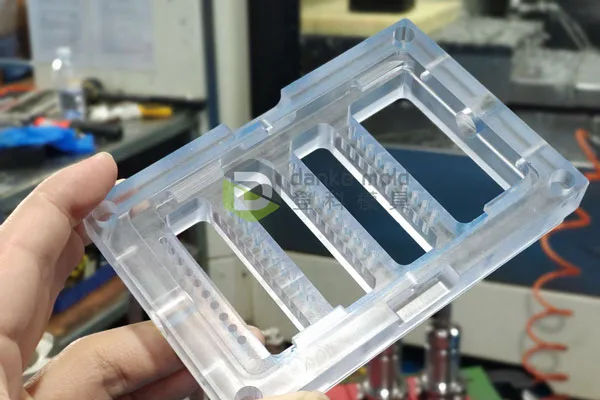

by Danke Mold | Apr 20, 2025 | Rapid Prototyping

Silicone molding is a versatile and widely used manufacturing process that involves creating molds from silicone rubber. This approach has several uses and benefits across various industries, including automotive, medical, consumer products, electronics, and more....

by Danke Mold | Apr 15, 2025 | Plastic Injection Molding

Blow molding has emerged as a viable solution for sustainable packaging alternatives. This manufacturing process allows lightweight containers that minimize material use while providing strength and durability. By adopting blow molding techniques, companies can...