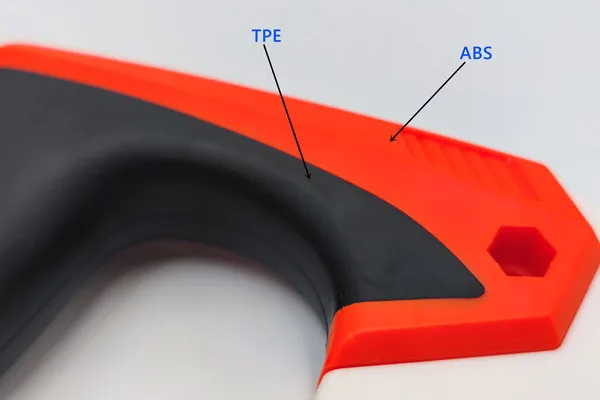

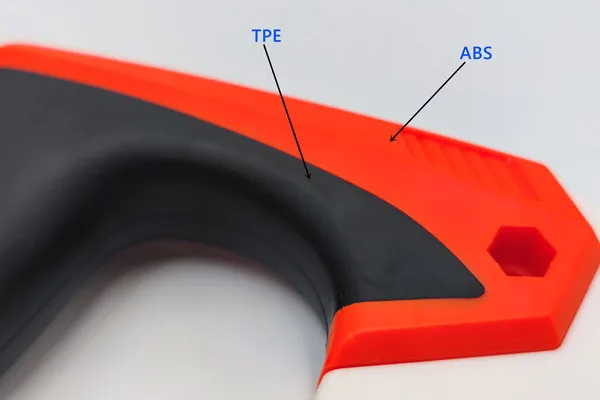

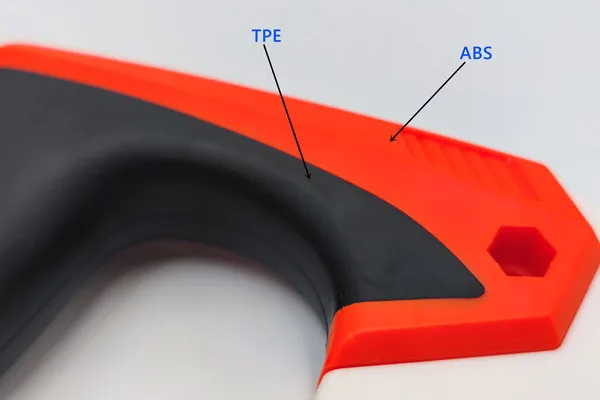

by Danke Mold | Nov 26, 2025 | Over Molding

Overmolding is absolutely critical in automotive control systems, where the fusion of rigid and soft materials directly impacts safety, functionality, durability and user experience. This application moves beyond simple comfort into the realm of precise human-machine...

by Danke Mold | Nov 24, 2025 | CNC Machining

In the highly regulated and life-dependent field of medical manufacturing, the choice of production technology is a critical determinant of success. CNC machining stands as a cornerstone process, offering an unparalleled combination of capabilities that align...

by Danke Mold | Nov 21, 2025 | Vacuum Casting

The ability to rapidly iterate designs and bring high-quality components to market more quickly is a critical advantage in the fast-paced and competitive automotive industry. Vacuum casting has emerged as the cornerstone technology to achieve this, serving as a vital...

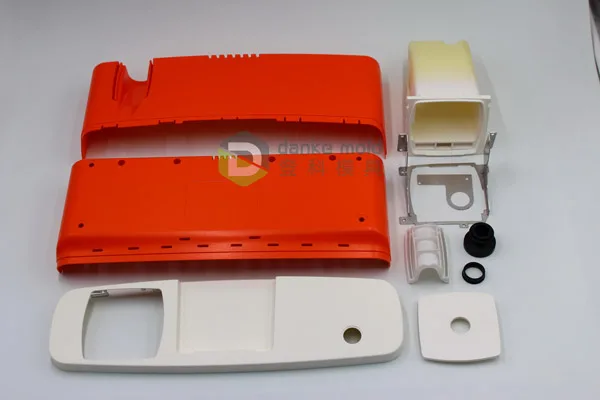

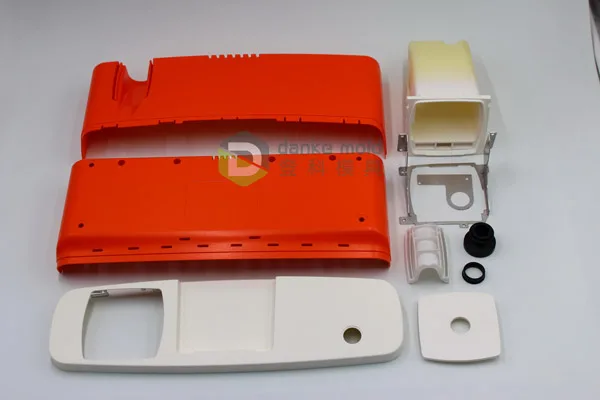

by Danke Mold | Nov 18, 2025 | Plastic Injection Molding

Look around any modern home – from the kitchen to the laundry room – and you are surrounded by sleek, seamless, durable appliance bodies made possible by plastic injection molding. This manufacturing process is the invisible force behind the form and...

by Danke Mold | Nov 14, 2025 | Rapid Tooling

In today’s fast-paced manufacturing landscape, the ability to move quickly from design to final product is a critical competitive advantage. Rapid Tooling has emerged as the cornerstone technology enabling this acceleration, bridging the gap between prototyping...