by Danke Mold | Mar 29, 2023 | Blog, Industry information, Rapid tooling & Injection molding

The characteristics of the injection mold are usually determined by the characteristics of the raw materials, there are two main points: one is the filling flow characteristics of the melt plastic pellet during injection, and the other is the shrinkage position of the...

by Danke Mold | Mar 27, 2023 | Blog, Industry information, Rapid tooling & Injection molding

The plastic waste has been one of the huge concerns and the plastic molding industry has come under a huge scanner in recent years. That is exactly why a plastic molding company is needs to work on the best sustainability options for achieving a more powerful...

by Danke Mold | Mar 21, 2023 | Blog, Industry information, Rapid tooling & Injection molding

When we think of plastic molding, choosing the right manufacturer would assume a lot essence for the success of your project. With such a huge number of plastic molding makers available, it is always quite practical to look for the best among them. This post is an...

by Danke Mold | Mar 17, 2023 | Blog, Industry information, Rapid tooling & Injection molding

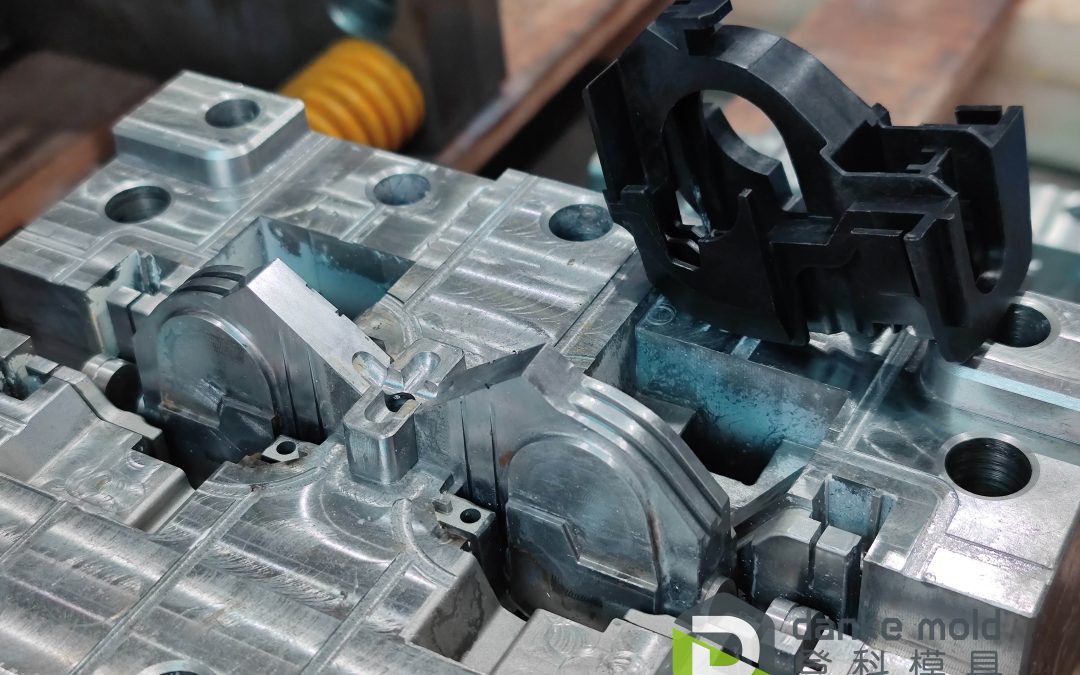

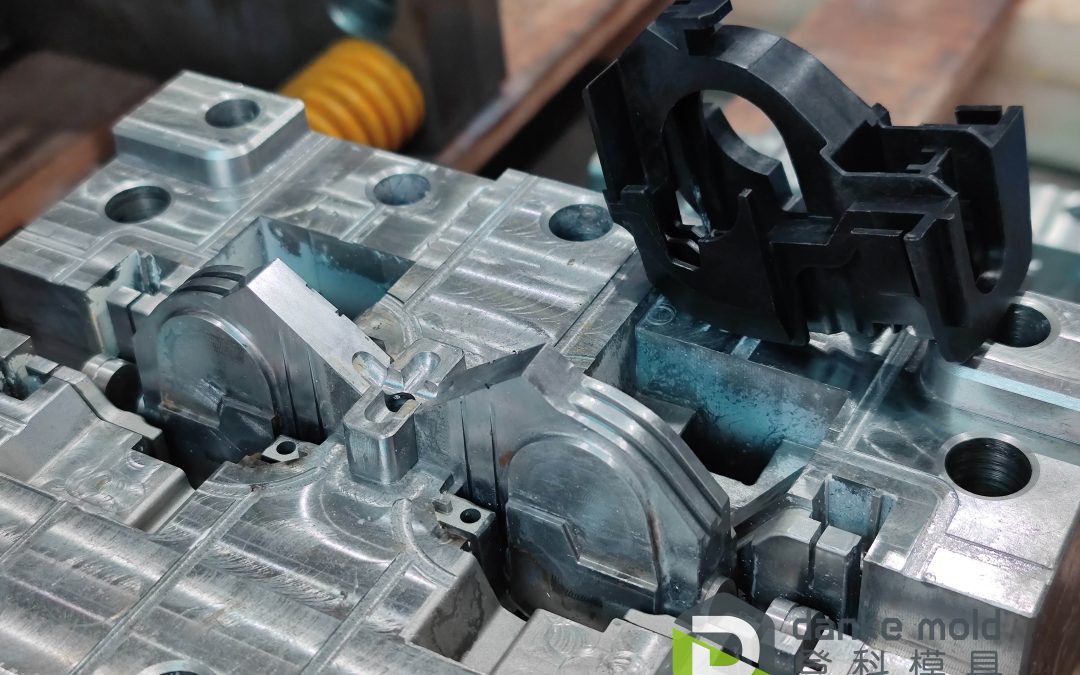

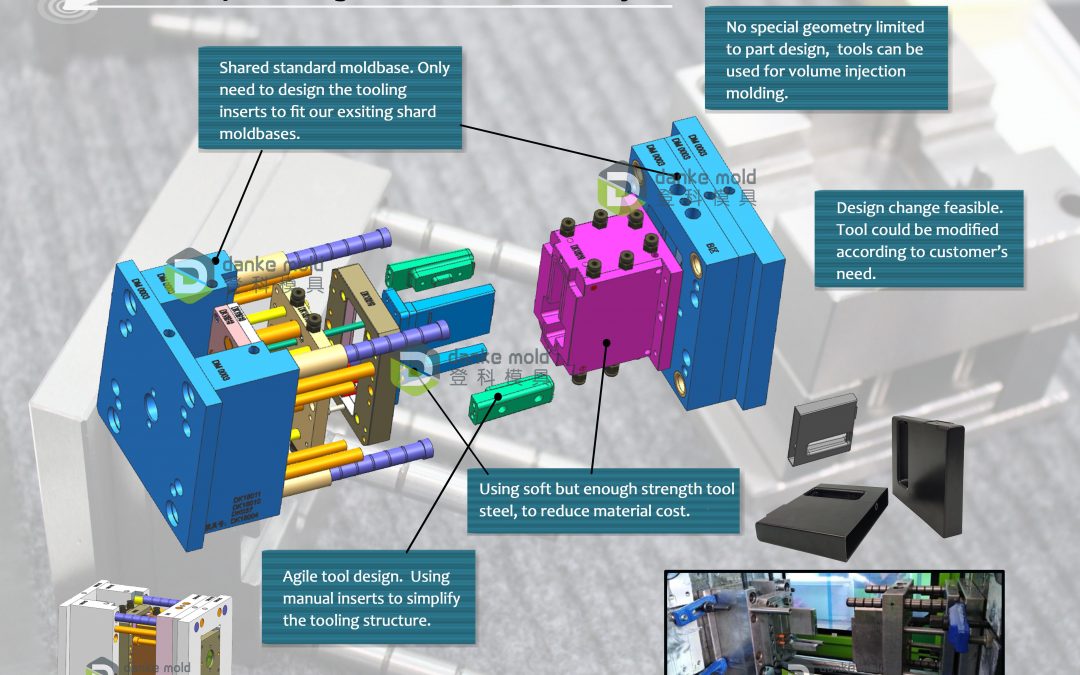

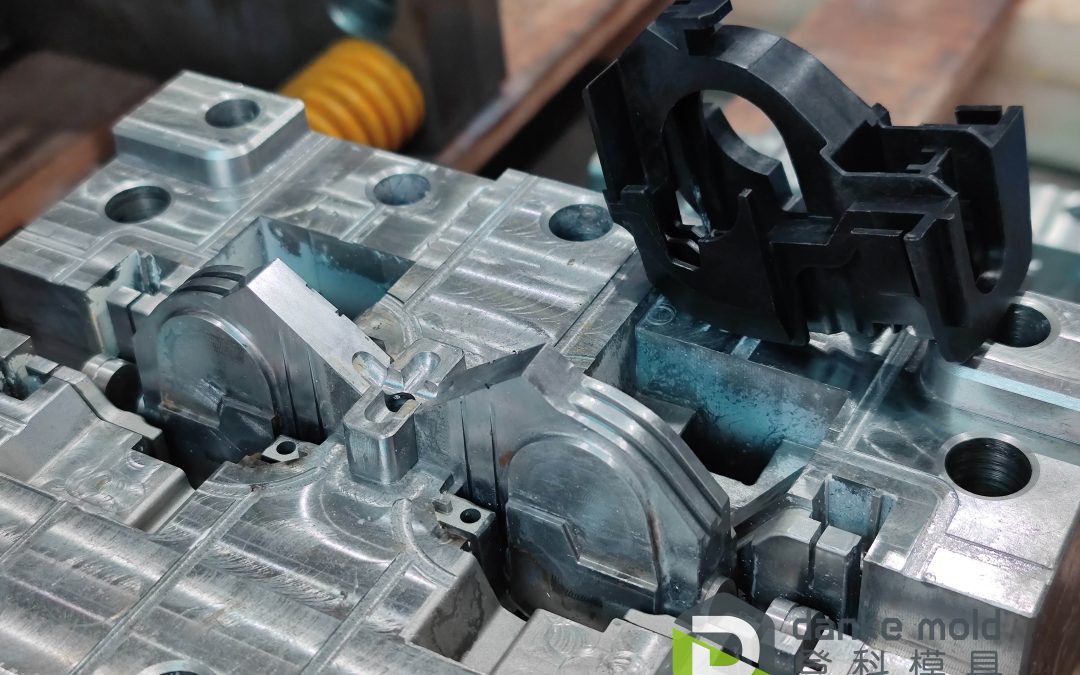

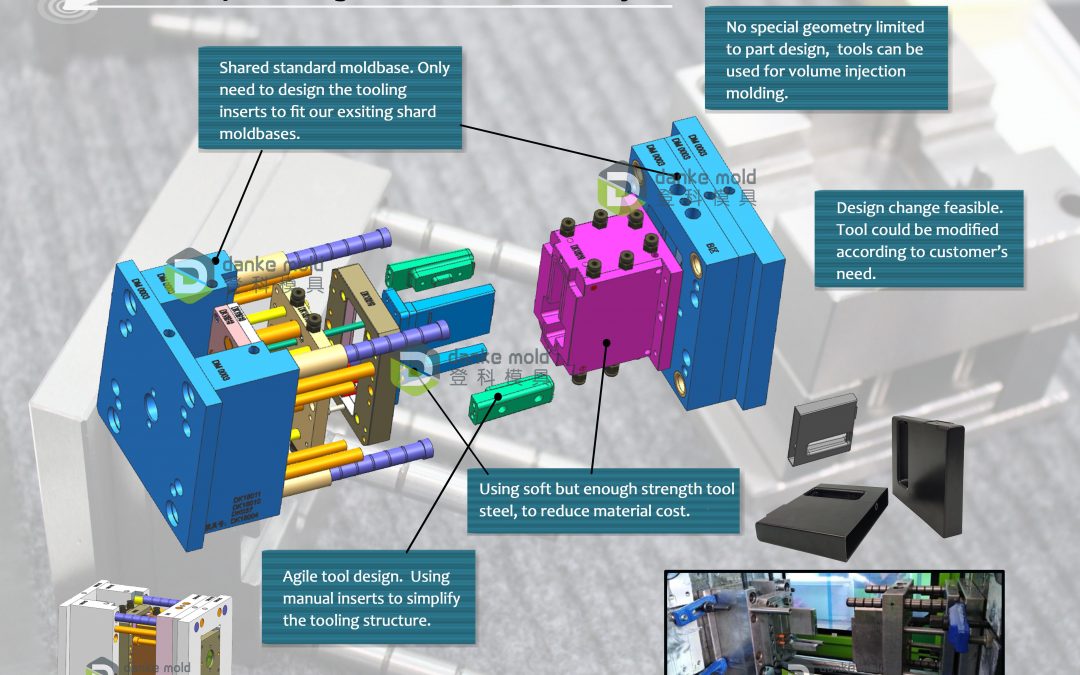

As a one-stop manufacturing services supplier, we’ve helped many customers to accomplish their product development in the past years, from initial prototyping, to low-volume production, with our services include rapid tooling & molding, CNC machining, 3D printing,...

by Danke Mold | Mar 14, 2023 | Blog, Industry information, Rapid tooling & Injection molding

We all know that it’s very important for a plastic molding company that has excellent manufacturing devices and skillful workers, as it’s a guarantee that they can producing good products at least. However, most of time, what customers’ want is not only acquiring...