by Danke Mold | Nov 18, 2024 | Vacuum Casting

It’s not too difficult to make a silicone mold. The item you wish to duplicate must first be created as a master model. A range of materials, including clay, wax, and even pre-existing objects, can be used for this. For the avoidance of air bubbles, make sure to...

by Danke Mold | Nov 12, 2024 | Vacuum Casting

Molds have been used by craftspeople throughout history to create anything from Bronze Age weapons to contemporary consumer goods. Although stone was often used to shape molds in the past, advances in science have led to the development of far more workable materials,...

by Danke Mold | Nov 9, 2024 | Vacuum Casting

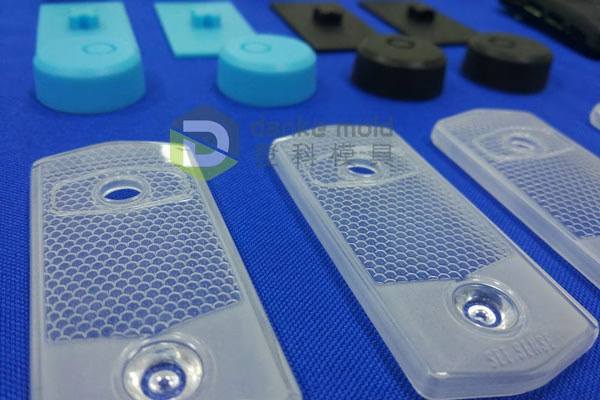

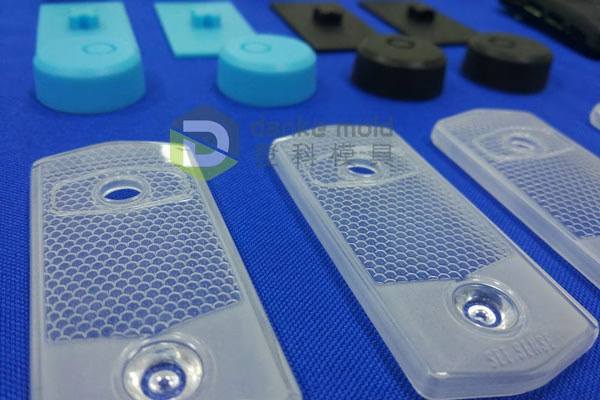

A silicone mold is created by pouring silicone rubber into a master mold or pattern and curing it. Silicone is a flexible synthetic rubber utilized in various sectors, including seals, tubes, and insulating paints and films. Since silicone has a silicon-to-oxygen...

by Danke Mold | Oct 1, 2024 | Vacuum Casting

In the fast-paced world of product development, where time-to-market is critical, rapid prototyping has emerged as an essential tool for bringing ideas to life. Among the various prototyping methods available, vacuum casting stands out for its versatility,...

by Danke Mold | Sep 12, 2024 | Vacuum Casting

In rapid prototyping, where speed and precision intersect, vacuum casting stands out as a technique that can replicate intricate details and surface finishes with unparalleled accuracy. This process has become the go-to choice for designers and engineers seeking...