by Danke Mold | Nov 14, 2025 | Rapid Tooling

In today’s fast-paced manufacturing landscape, the ability to move quickly from design to final product is a critical competitive advantage. Rapid Tooling has emerged as the cornerstone technology enabling this acceleration, bridging the gap between prototyping...

by Danke Mold | Sep 21, 2025 | Rapid Tooling

In today’s highly competitive manufacturing landscape, the ability to produce high-quality products quickly and efficiently is critical. Traditional methods of tooling, while reliable, often involve lengthy lead times and high costs, which can hinder innovation...

by Danke Mold | Aug 16, 2025 | Rapid Tooling

Heavy machinery downtime costs industrial operations thousands of dollars per hour, yet traditional spare parts procurement often requires weeks or months of lead time. When critical equipment fails and replacement parts are unavailable, production grinds to a halt...

by Danke Mold | Jan 9, 2025 | Rapid Tooling

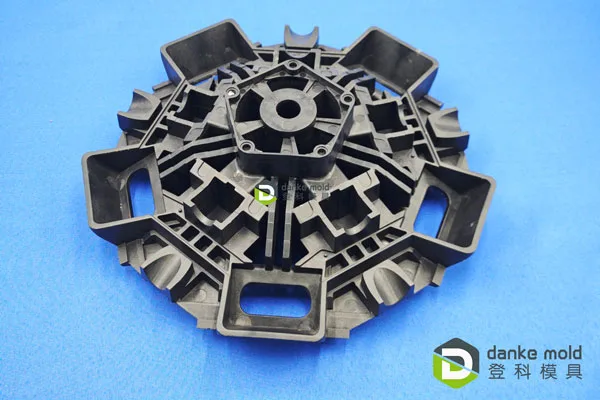

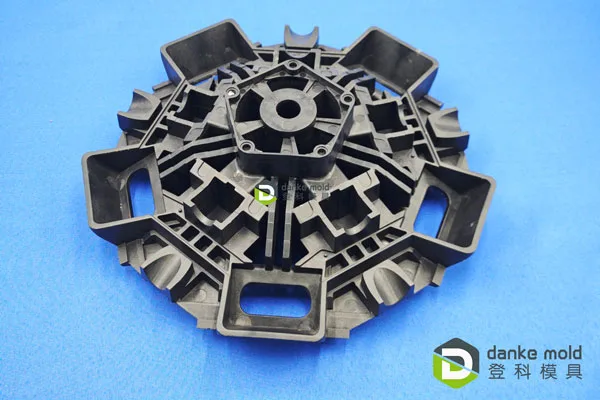

Rapid Tooling refers to processes or technologies that enable the rapid manufacture of tooling components such as molds or dies. Injection Mold Tooling is a popular practice in the manufacturing sector because it enables the rapid and low-cost production of...

by Danke Mold | Dec 20, 2024 | Rapid Tooling

Today’s fast-paced manufacturing needs unmatched speed and precision. Manufacturers want to increase output, lower prices, and enhance quality. This method changed with rapid tooling. Rapid tooling allows companies quickly create high-quality prototypes and...

by Danke Mold | Dec 6, 2024 | Rapid Tooling

This crucial stage of product development is also known as – prototype tooling or bridge tooling. It makes use of materials like- -mild steel or aluminum, -hand-loaded inserts, and -a common mold base. Rapid tooling is a – quick and economical –...