by Danke Mold | Feb 22, 2026 | Plastic Injection Molding

The plastic injection molding industry has long been a cornerstone of manufacturing, enabling the mass production of countless everyday items—from automotive parts and consumer electronics to medical devices and packaging. As global concerns about environmental...

by Danke Mold | Feb 6, 2026 | Plastic Injection Molding

Plastic injection molding is a manufacturing process that has revolutionized the way industries produce a wide array of products. From everyday household items to complex automotive components, this technique offers unparalleled advantages, making it the choice of...

by Danke Mold | Feb 3, 2026 | Plastic Injection Molding

Plastic injection molding is one of the most widely used manufacturing processes in the world of plastics. Its ability to produce complex, high-precision components at high volume makes it indispensable across a wide range of industries, from automotive and consumer...

by Danke Mold | Jan 28, 2026 | Plastic Injection Molding

Few processes in the industrial production landscape are as synonymous with efficiency, scale and innovation as plastic injection molding. It has been the backbone of mass-produced plastic parts for decades, from the simplest bottle caps to complex automotive and...

by Danke Mold | Jan 26, 2026 | Plastic Injection Molding

For decades, 3D printing, also known as additive manufacturing, was perceived as a futuristic novelty – a tool for hobbyists and a costly fast prototyping machine for large corporations. Today, that perception has fundamentally shifted. 3D printing has matured...

by Danke Mold | Jan 23, 2026 | Plastic Injection Molding

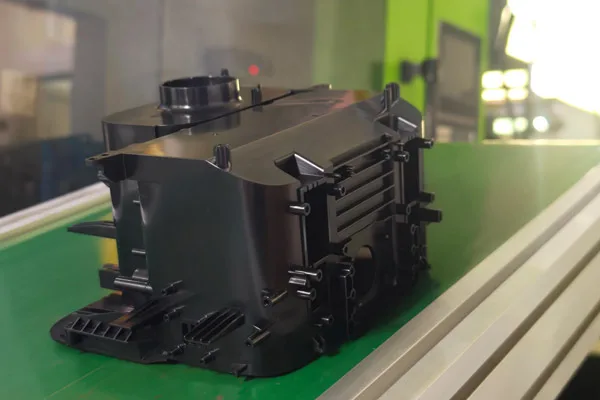

The morning ritual is nearly universal: the scoop of grounds, the pour of water, the press of a button, and the anticipatory gurgle leading to that first, essential cup. While coffee aficionados rightly focus on the origin, roast and grind size of the beans, there is...