6 Frequent-use Terms at Rapid Tooling

We worked a lot of rapid tooling and injection molding jobs for customers all over the world. Sometimes our new customer may be a bit confused at the terms we used during quotation, or project management. We would like to share 6 frequent-use terms at rapid tooling, so that we may have a better communication in the coming days.

Rapid Tooling:

Alternative name: proto mold, bridge tooling, quick-turn injection mold.

It’s for molding prototype, low volume production, and on-demand injection molding.

It’s a simplified injection mold, for cost saving and risk reduction, at product development.

MUD Mold Base:

Abbreviation of mater unit die.

It’s a widely use mold base system, for common use to save tooling cost.

Rapid tooling of small components or simple parts, often use MUD mold base.

–Image from DME

–Image from DME

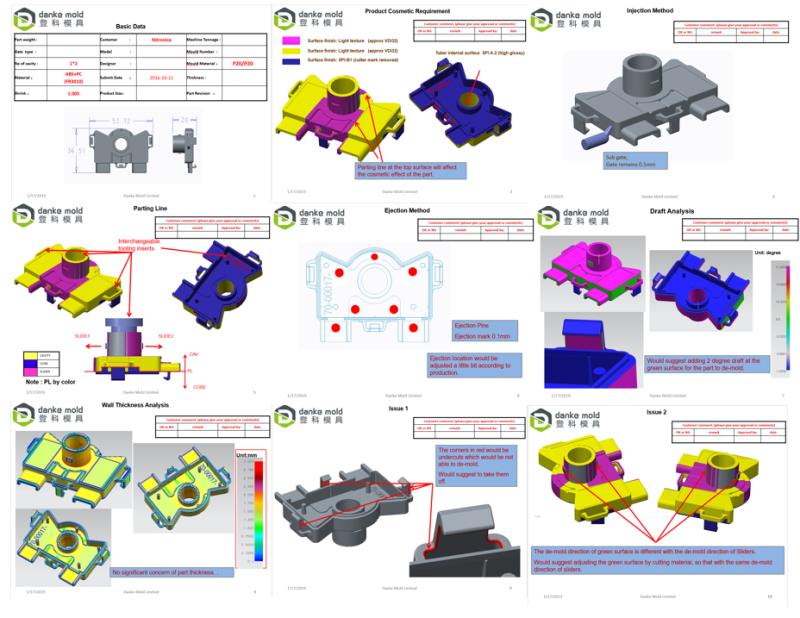

DFM Analysis:

Abbreviation of Design for Manufacturing Analysis.

A process of part design review. It’s to avoid potential manufacturing issues of mold making or injection molding, before tool building start.

It includes the analysis of gate position, parting line, ejection method, tooling structure, draft, wall thickness, and other tooling & molding issues.

–A DFM analysis sample of LED Lighting Case

Manual Insert

Alternative name: hand-loaded insert, hand load, hand slide, hand pick out.

It’s a simplified tooling component, comparing with sliders or lifters

It’s for undercuts of injection molding part, to de-mold.

Soft Tooling:

It’s named because of its tooling insert material.

In normal, these materials will be aluminum 7075, carbon steel C50#, semi-harden steel P20.

Soft tooling basically is a proto mold, rapid tooling.

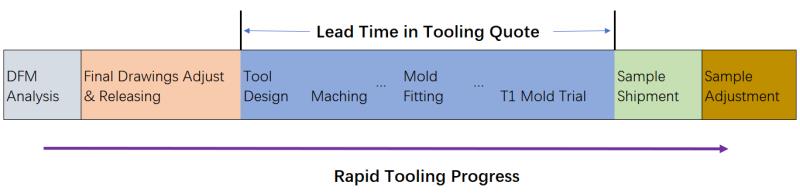

Lead Time:

We meant the lead time in our Tooling quotationh here.

It’s the lead time from tooling building until T1 samples run.

Including mold design, programming, CNC machining, EDM sparking, wire cutting, mold fitting, assembly, mold trial of T0 & T1 samples.

Not including the time of quotation, DFM analysis, 3D model adjustment, at upfront stage.

Not including the time of sample shipment, and sample tuning, at later stage.

As it would be a bit confusing for our new customers, we try to clarify the lead time that we meant in our tooling quote here.

Danke Mold is keen to shorten the lead time for our customers.

We provide details design for manufacturing analysis from the very begging of quotation, high efficiency communication, high quality T1 samples, swift production arrangement. It would help saving cost and shortening lead time for our customers.

Danke Mold keep optimizing our process and capacity. We will let you know more in our blog or company news if any significant update.

Meanwhile, should you have any manufacturing enquiries at rapid tooling, proto mold making, or up-coming project need injection molding parts, just email us via info@dankemold.com. We will response in 12 hours.