In the world of manufacturing, choosing the right production process is crucial to ensure efficiency, quality and cost-effectiveness. Of the various methods available, plastic injection molding has established itself as the dominant technique for the mass production of plastic parts and products. Its versatility, high output capacity and ability to produce complex designs with precision make it the choice of choice for a myriad of industries from automotive to consumer electronics.

What is Plastic Injection Molding?

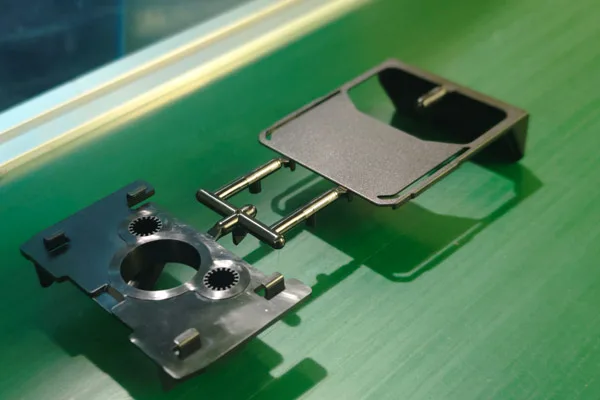

Plastic injection molding is a manufacturing process in which molten plastic material is injected into a precisely designed mold cavity. Once cooled and solidified, the mold opens, and the finished part is ejected. This process is highly automated and can produce large quantities of identical parts quickly and consistently.

Key Advantages of Plastic Injection Molding

High Production Efficiency and Speed

One of the primary reason injection molding is favored for mass production is its ability to rapidly produce large volumes of parts. Once the initial tooling is ready, cycle times can be as short as a few seconds to a few minutes, enabling manufacturers to produce thousands or even millions of parts in a relatively short period of time. This high throughput significantly reduces the cost per unit, making it economically viable for large-scale manufacturing.

Cost-Effective for Large Quantities

While the upfront cost of designing and manufacturing the mold can be substantial, the per-unit cost decreases dramatically with volume. The economies of scale achieved through injection molding make it an attractive option for large production runs, especially when compared to other manufacturing methods such as machining or casting.

Ability to Produce Complex and Precise Parts

Injection molding can create intricate designs with tight tolerances that would be difficult or impossible with other processes. This includes detailed features, undercuts, and complex geometry. The process also allows the integration of multiple functions into a single part, reducing assembly requirements and improving overall product quality.

Wide Range of Material Options

The process supports a wide array of thermoplastic and thermoset materials, including ABS, polycarbonate, nylon, polypropylene and many others. This flexibility allows manufacturers to select materials with specific properties, such as strength, flexibility, heat resistance or chemical resistance, tailored to the application requirements.

Excellent Surface Finish and Aesthetic Quality

Injection molding parts often have smooth surface finishes and can incorporate colors, textures, and other aesthetic features directly into the mold. This capability reduces the need for post-processing or finishing, further reducing production costs and lead times.

Consistency and Repeatability

Once the mold design is refined, injection molding produces highly consistent parts with minimal variability. Such repeatability is essential for industries such as aerospace, medical devices and electronics, where precision and reliability are paramount.

Plastic parts

Industry Applications of Injection Molding

The versatility of plastic injection molding makes it suitable for a broad spectrum of applications:

- Automotive Industry: Instrument panels, door handles, light housings, and interior trims.

- Consumer Electronics: Smartphone casings, remote controls, and connectors.

- Medical Devices: Syringe bodies, diagnostic components, and surgical instruments.

- Packaging: Bottle caps, containers, and dispensing mechanisms.

- Household Goods: Kitchen utensils, storage bins, and decorative items.

Future Trends in Plastic Injection Molding

Advances in technology continue to enhance the capabilities of injection molding:

Rapid tooling and 3D-printed molds reduce lead times for prototypes and small batches.

Automation and robotics increase efficiency and reduce labor costs.

Smart molds equipped with sensors enable real-time monitoring and quality control.

Sustainable materials and recycling practices are increasingly incorporated into the process to minimize environmental impact.

Conclusion

Plastic injection molding remains the leading choice for mass production due to its unparalleled efficiency, precision and versatility. Its ability to produce high-quality, complex components at a low per-unit cost makes it indispensable across industries. As technological innovations continue to emerge, the role of plastic injection molding in manufacturing is poised to grow even further, maintaining its position as the cornerstone of large-scale plastic part production.