In the exhilarating race to market, where every second counts, businesses constantly seek ways to accelerate their product development process. It’s a race fueled by innovation, where the swift and agile reign supreme. In this high-stakes competition, rapid prototyping emerges as the ultimate speed booster, a secret weapon for those who dare to innovate at lightning speed.

At Danke Mold, we’re passionate about empowering businesses to accelerate their journey from concept to reality. Rapid prototyping is more than just a technique; it’s a philosophy that embraces speed, efficiency, and the relentless pursuit of innovation.

So, buckle up and prepare to be amazed as we explore the arsenal of rapid prototyping techniques that can turbocharge your product development process.

Additive Manufacturing (3D Printing)

Imagine a technology that can conjure up objects from thin air, layer by layer, with intricate details and mind-boggling complexity. That’s the magic of 3D printing, a process that has revolutionized the prototyping world.

- How it Works: A digital design is fed into a 3D printer, which then meticulously builds the object by layering molten plastic, resin, or even metal.

- Speed Advantage: 3D printing offers unparalleled speed in creating custom designs and complex geometries, allowing for rapid iterations and design modifications.

- Applications: From medical devices and aerospace components to consumer products and architectural models, 3D printing accelerates product development across diverse industries.

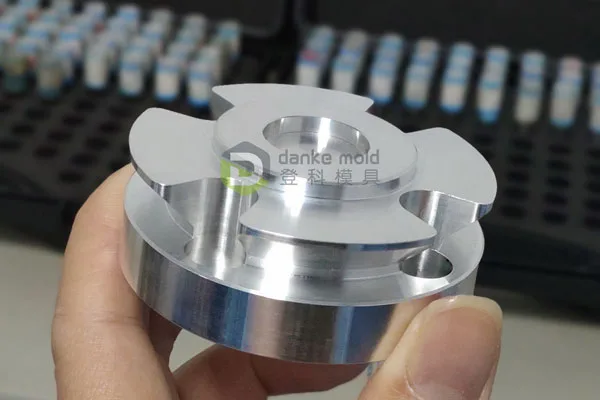

CNC Machining

When accuracy and durability are paramount, CNC machining takes center stage. This technique employs computer-controlled tools to carve out precise shapes from solid blocks of material, producing high-quality prototypes with exceptional detail.

- How it Works: A digital design guides the CNC machine, which uses cutting tools to precisely shape the material, creating intricate parts with tight tolerances.

- Speed Advantage: CNC machining offers high speed and efficiency in producing functional prototypes, especially for parts that require durability and precision.

- Applications: From automotive components and aerospace parts to industrial machinery and tooling, CNC machining is accelerating product development in industries where precision and strength are critical.

CNC machining parts

Injection Molding

For high-volume production and testing, injection molding reigns supreme. This technique involves injecting molten plastic into a mold, creating identical parts with incredible speed and consistency.

- How it Works: Molten plastic is injected into a mold cavity, where it cools and solidifies, taking the shape of the mold.

- Speed Advantage: Once the mold is created, injection molding allows for rapid production of large prototypes, ideal for testing and validation.

- Applications: From consumer electronics and packaging to medical devices and automotive components, injection molding accelerates product development for high-volume production and testing.

Vacuum Casting

Need multiple copies of a prototype? Vacuum casting is your answer. This technique uses a silicone mold to create replicas of a master pattern, offering high fidelity and relatively quick turnaround times.

- How it Works: A silicone mold is created from a master pattern. Liquid resin is then poured into the mold and a vacuum is applied to remove air bubbles, ensuring a high-quality replica.

- Speed Advantage: Vacuum casting allows for relatively quick production of small batches of high-quality prototypes, ideal for testing and evaluation.

- Applications: From consumer products and electronics to automotive parts and medical devices, vacuum casting accelerates product development when multiple design copies are needed.

Rapid Tooling

Traditional tooling can be a time-consuming bottleneck in product development. Rapid tooling, however, utilizes rapid prototyping techniques to create molds and tooling much faster, significantly reducing lead times.

- How it Works: Rapid prototyping techniques like 3D printing or CNC machining are used to create molds and tooling for production.

- Speed Advantage: Rapid tooling drastically reduces the time required to create production-ready tooling, accelerating product development.

- Applications: From injection molding and die casting to stamping and thermoforming, rapid tooling accelerates product development by quickly creating the necessary tools for production.

Shift Your Product Development into Overdrive

In the race against time, where innovation is the fuel and speed is the key, rapid prototyping emerges as the ultimate accelerator, propelling businesses toward success. By embracing these powerful techniques, you can unlock new levels of efficiency, reduce your time-to-market, and gain a decisive competitive edge.

Ready to shift your product development into overdrive? Contact Danke Mold today. Let’s explore how our expertise in 3D printing, CNC machining, injection molding, vacuum casting, and rapid tooling can help you accelerate your journey from concept to reality. The future of innovation is fast – let’s embrace it together.