Plastic injection molding is a complex and intricate process that involves both art and science in it. It requires a deep understanding of the materials, the machines, and the design process to create high-quality products that meet the needs of customers in every sense of the word. In this blog post, we will delve into the art and science of plastic injection molding design and explore the key considerations that go into creating successful designs. Most of the plastic injection molding company options that you would find quite impressive and engaging.

The Science of Plastic Injection Molding Design:

The science of plastic injection molding design involves the technical aspects of the process in it. This includes the selection of materials, the design of the mold, the machine settings, and the manufacturing process itself to name a few. It is important to consider factors such as the shrinkage rate of the plastic, the pressure required for the injection, and the cooling time required to prevent warping or distortion of the finished product. If you are a plastic injection molding company that loves to build a huge portfolio, it is advisable to check out the right options in terms of all the components.

The Art of Plastic Injection Molding Design:

The art of plastic injection molding design involves the creative and aesthetic aspects of the process. This includes the shape, size, and color of the product, as well as the texture and finish of the surface. A successful design requires an understanding of the intended use of the product and the target audience. It is important to consider factors such as ergonomics, usability, and branding. It would be a good idea to give a complete insight into the multiple factors that the injection molding design needs to focus on.

Design Considerations:

When designing a product for plastic injection molding, it is important to consider a variety of factors to ensure a successful outcome. Some of the key considerations that you may need to pay a special attention would include:

Material selection: The choice of material will impact the final product’s characteristics, such as strength, flexibility, and durability. Choosing the right product is quite important.

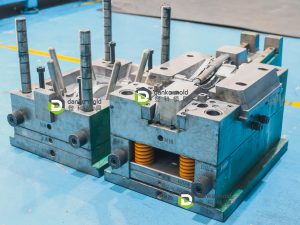

Mold design: The mold must be designed to accommodate the desired shape and size of the product, as well as any necessary undercuts or internal features.

Machine settings: The machine settings must be optimized to ensure the plastic is injected at the correct pressure and temperature.

Cooling time: Sufficient cooling time is required to prevent the finished product from warping or distorting.

Aesthetics: The design must take into account the desired color, texture, and finish of the product.

Conclusion:

Plastic injection molding design requires both art and science to create high-quality products that meet the needs of customers. A successful design requires a deep understanding of the materials, the machines, and the design process, as well as the creative and aesthetic aspects of the product. By considering a variety of factors, designers can create products that are functional, aesthetically pleasing, and cost-effective to manufacture.