by Danke Mold | May 24, 2025 | Rapid Prototyping

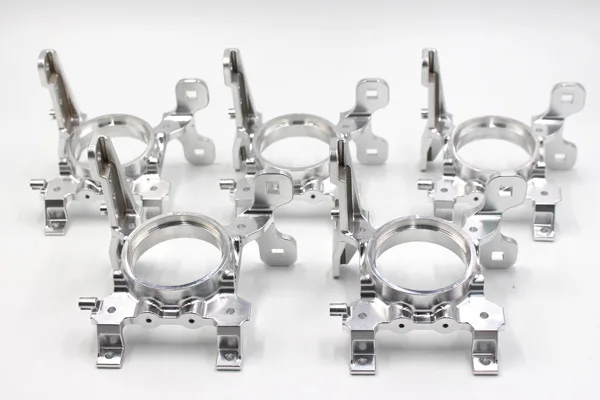

In today’s rapidly evolving product development landscape, low-volume manufacturing is crucial in specialized products, prototype development, and niche market applications. Amid supply chain disruptions and market uncertainties, low-volume manufacturing offers...

by Danke Mold | Jan 3, 2025 | Rapid Prototyping

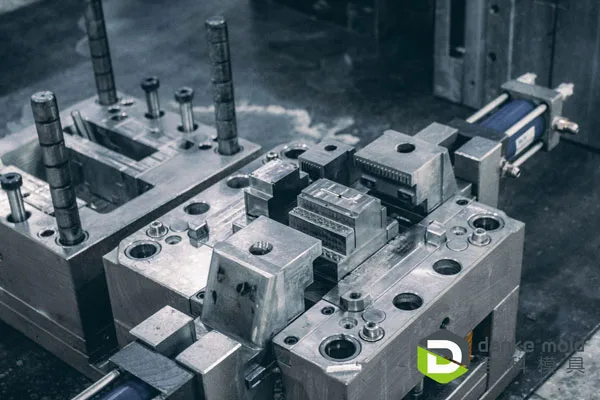

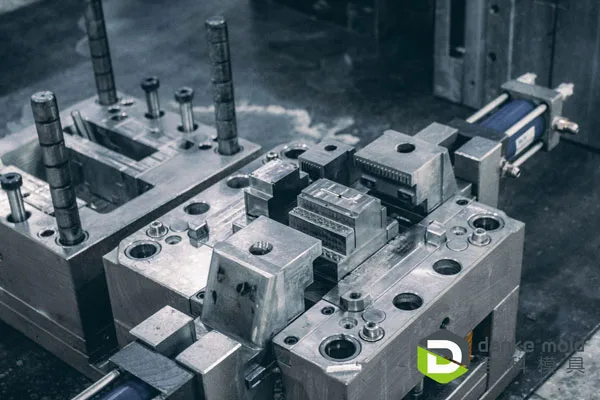

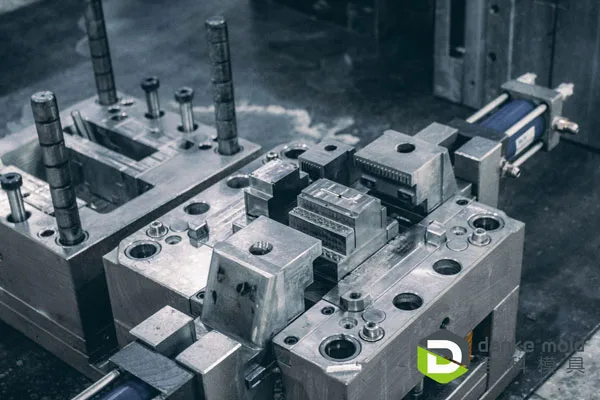

Rapid tooling has changed production in the fast, precise age. Rapid tooling makes tools rapidly and inexpensively using additive manufacturing and advanced machining. Rapid tooling’s advantages and utilization in various industries make it crucial in modern...

by Danke Mold | Dec 20, 2024 | Rapid Tooling

Today’s fast-paced manufacturing needs unmatched speed and precision. Manufacturers want to increase output, lower prices, and enhance quality. This method changed with rapid tooling. Rapid tooling allows companies quickly create high-quality prototypes and...

by Danke Mold | Dec 6, 2024 | Rapid Tooling

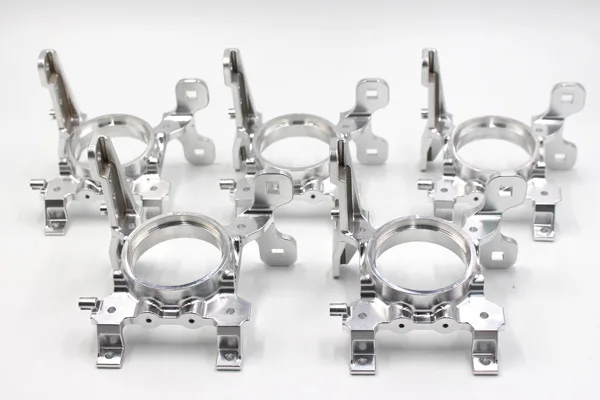

This crucial stage of product development is also known as – prototype tooling or bridge tooling. It makes use of materials like- -mild steel or aluminum, -hand-loaded inserts, and -a common mold base. Rapid tooling is a – quick and economical –...

by Danke Mold | Nov 21, 2024 | Rapid Prototyping

In today’s fast-paced industrial world, speed and efficiency drive digital innovation. Manufacturers can build prototypes and production-ready tools faster and cheaply via rapid tooling (RT). Fast prototyping and standard manufacturing are transforming how firms...