by Danke Mold | Jan 23, 2026 | Plastic Injection Molding

The morning ritual is nearly universal: the scoop of grounds, the pour of water, the press of a button, and the anticipatory gurgle leading to that first, essential cup. While coffee aficionados rightly focus on the origin, roast and grind size of the beans, there is...

by Danke Mold | Jan 20, 2026 | Plastic Injection Molding

In the world of manufacturing, choosing the right production process is crucial to ensure efficiency, quality and cost-effectiveness. Of the various methods available, plastic injection molding has established itself as the dominant technique for the mass production...

by Danke Mold | Jan 13, 2026 | Plastic Injection Molding

Plastic injection molding has long been a cornerstone of manufacturing, especially in the production of complex plastic parts with high accuracy and efficiency. Over the decades, the industry has undergone a remarkable transformation, driven by technological...

by Danke Mold | Jan 5, 2026 | Plastic Injection Molding

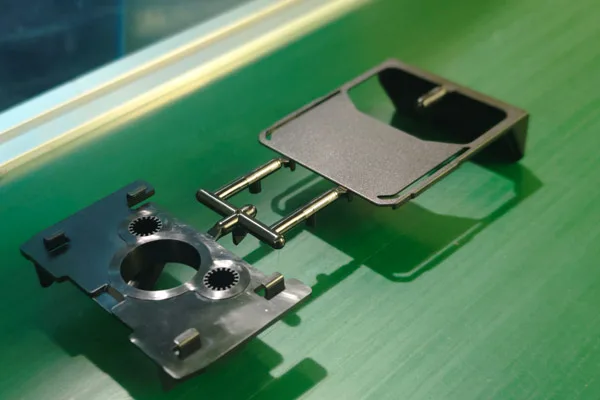

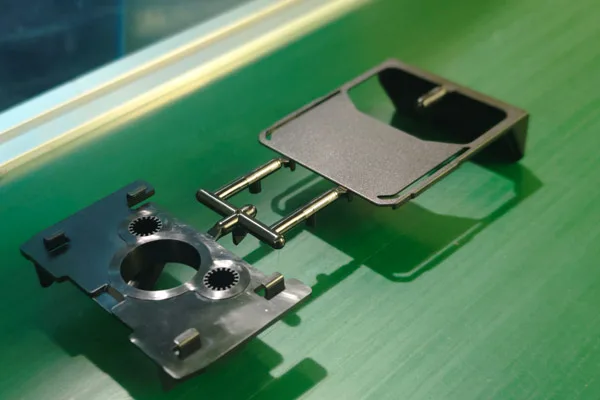

In the rapidly evolving world of home appliances, manufacturers are continually seeking materials and manufacturing processes that provide durability, cost-effectiveness and design flexibility. Of the various manufacturing techniques available, plastic injection...

by Danke Mold | Dec 29, 2025 | Plastic Injection Molding

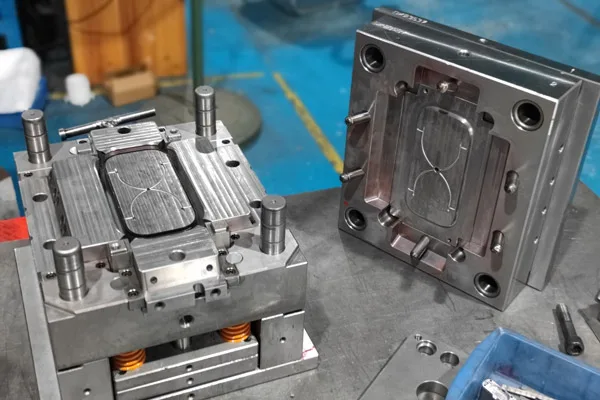

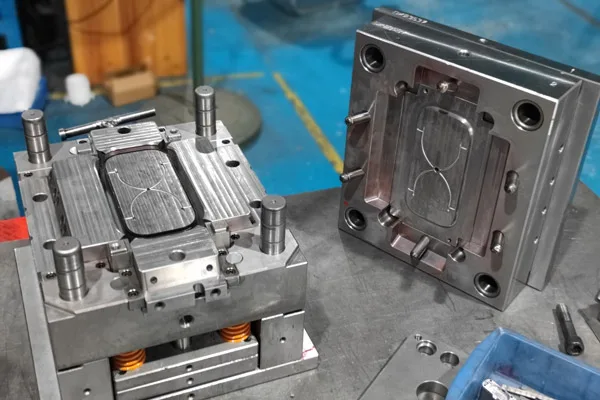

In today’s fast-paced world, smartphones have become essential to daily life. Consequently, the demand for durable, stylish, and personalized phone cases has grown significantly. One of the most efficient and widely used methods for producing high-quality cases...