by Danke Mold | Mar 3, 2026 | Plastic Injection Molding

Selecting the right plastic for injection molding is a critical step in ensuring the success of your manufacturing project. The right material affects not only the quality and durability of the final product, but also production efficiency, cost and compliance with...

by Danke Mold | Feb 22, 2026 | Plastic Injection Molding

The plastic injection molding industry has long been a cornerstone of manufacturing, enabling the mass production of countless everyday items—from automotive parts and consumer electronics to medical devices and packaging. As global concerns about environmental...

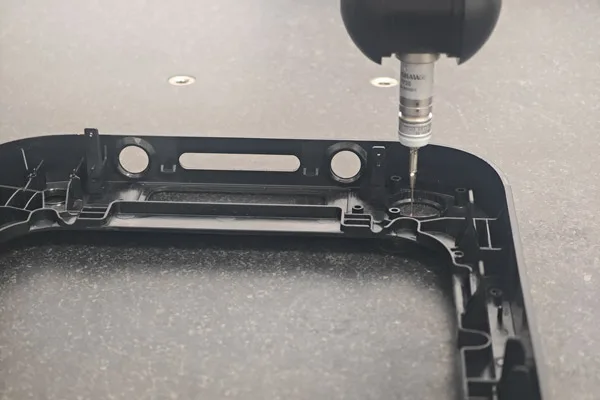

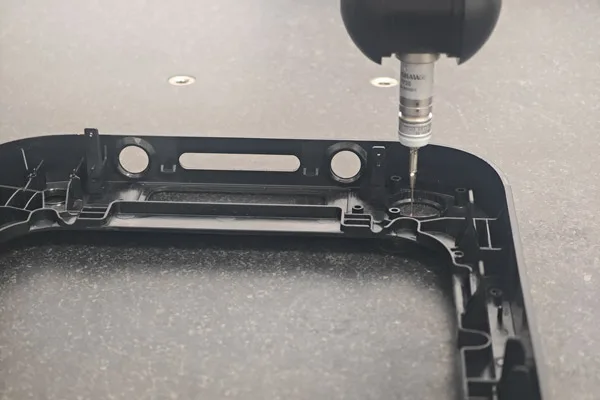

by Danke Mold | Feb 6, 2026 | Plastic Injection Molding

Plastic injection molding is a manufacturing process that has revolutionized the way industries produce a wide array of products. From everyday household items to complex automotive components, this technique offers unparalleled advantages, making it the choice of...

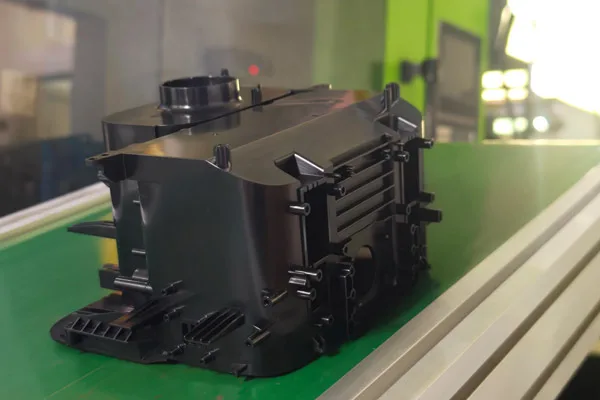

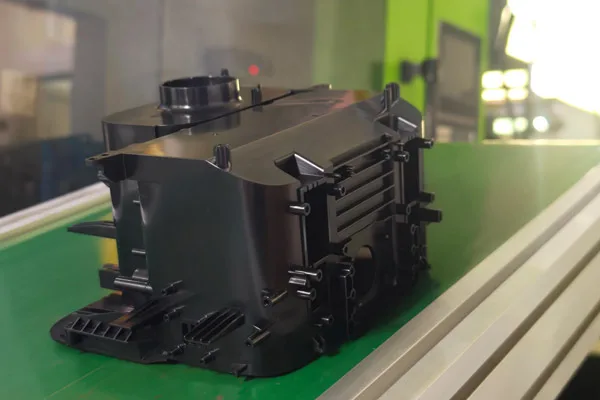

by Danke Mold | Feb 3, 2026 | Plastic Injection Molding

Plastic injection molding is one of the most widely used manufacturing processes in the world of plastics. Its ability to produce complex, high-precision components at high volume makes it indispensable across a wide range of industries, from automotive and consumer...

by Danke Mold | Jan 28, 2026 | Plastic Injection Molding

Few processes in the industrial production landscape are as synonymous with efficiency, scale and innovation as plastic injection molding. It has been the backbone of mass-produced plastic parts for decades, from the simplest bottle caps to complex automotive and...