Today we are talking about “Rapid Tooling” from another perspective. “Rapid tooling” is a term that can have different meanings to different people.

To a product designer it means a relatively low cost, fast made non-production tool used to make a low volume of prototype parts.

To a mold-maker, it indicates a mold that has been built to demonstrate where a tool will perform as expected.

To a project management, sometimes it means “prototype tooling”, and that is the theme we are discussing today. Though the key points in either case are relatively inexpensive and relatively fast turnaround as compared to production tools.

Prototype molds are defined as molds that are built in the least cost and manual possible to produce a small quantity of prototype parts. Prototype tooling budgets should include the costs of mold modifications and the cost of printed master model. Even when molds are made by CNC machining, the models are still very helpful. Comparing to the cost of modification for production tool to meet the tool or part modification, the money and time that spend on prototype molding steps may be small

Normally, prototype tools are required to produce parts that are very similar to the designed production parts. The prototype part’s production turnaround time may be more or less longer than that of the production tool because of the reducing of cooling system or because the tool uses some manual inserts or sliders.

For those high quality aluminum rapid tools, production cycles can be shorter due to the improved heat transfer. The parts produced in prototype tools may also need some additional post operations or post finishing by hand. Prototype tools are usually manufactured for producing a limited number of parts (from several pieces to hundred parts or even thousands.of parts in some projects) although metal production tooling often end up in production for some special reasons.

Another important reasons for using prototype tools is to make prototype parts for lab experiment. Only injection molded samples manufacture using the production material will show the real properties of the final product, because factors such as setup, heating system, weld lines and other processing related effects need to be considered.

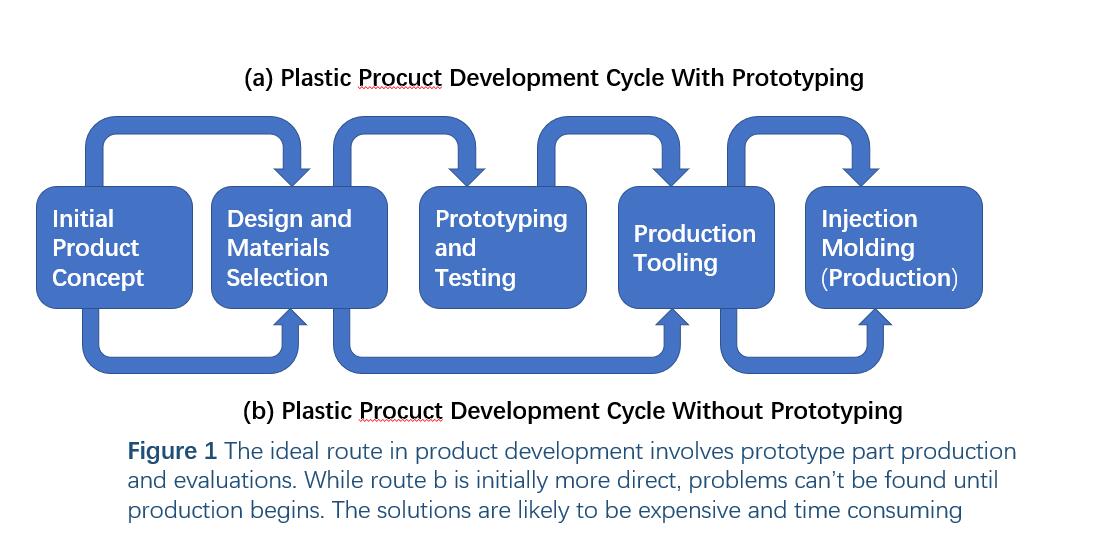

While injection molded prototype components and molds is relatively expensive to 3D printed/CNC machined prototypes (especially when only several pieces of parts are required), unforeseen manufacturing or processing related part performance problems are less likely to occur when manufacturing considerations are taken into account.

The prototype tools usually be designed as with single cavity molds rather than multi-cavity, and there’s always lack of some certain details such as trademarks or laser etched marks. The unit cavity is common for smaller parts. However ,for larger size parts, the prototype tooling are more difficult to make, because the cost of the prototype tool becomes very significant compare to a production tool.

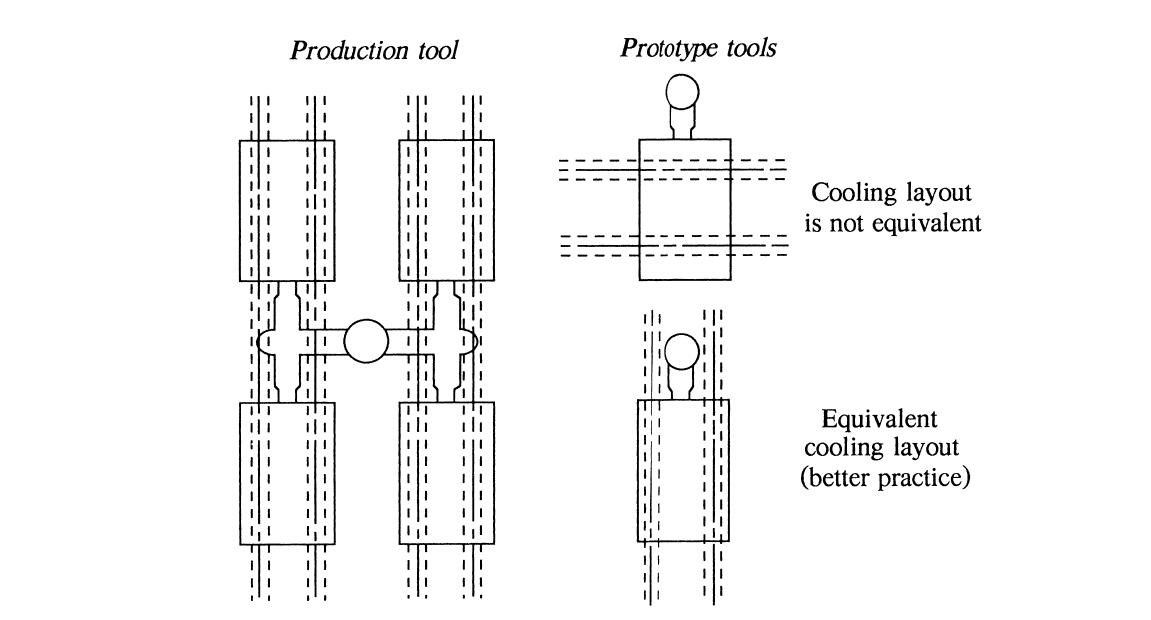

There’s a potential problem need to be paid attention for larger parts, such as the weld line on the external automotive panel, this can be considered to use much simpler prototype tooling. In such a case, it is important to keep processing conditions and tooling structure as realistic as possible. The prototype tools should be constructed similar to the production tool according to runner systems, type/location of the gate(s) and cooling systems an so on. Moreover, it may be better to design a prototype tool so that it is multifunctional. Something like, a number of gating proposal could be combined into the tool upfront, please see the picture of gate location as below:

Figure 2 Cooling layouts for prototype molds should reflect the planned production cooling layout

For many cases, prototype parts are manufactured only for appearance checking but not non-engineering functions, such as those required for sample/ assembly display, or marketing test purposes. These parts might be produced using lower melting, weaker material, along with softer, cheaper tooling and manual finishing, generating parts that are good enough as 3D printed prototypes or CNC machined parts。

Prototype molds can be classified according to the production characteristics or their materials of manufactured The prototype injection molds can be sand cast, 3D printed, or CNC machined which is most common. Cast prototype tools require the use of a master model which can be made from plaster, plastic, wax or from a soft metal just like aluminum. The master model material selection is depend on factors such as the temperature related with the tool casting operation.

There’s difference with many aspects between prototype tool and production tool as following:

1) Materials to be used for the cavity/ core.

2) Number of cavities and core

3) Type of cooling system

4) Amount of working automation

5) Amount of polishing work on the mold

6) Type of runner system, gating system.

It really worth for you to make a prototype tool for small parts that will have high production afterwards ,because the cost will be easily figured out. The worst situation is to make a prototype mold for large parts that will have low production. In our opinion, the cost, lead time, and how realistic will the part reflect should be considered when we making decision for making a prototype mold