Danke Mold Blog

We would just like to share our rapid tooling, plastic injection molding and on-demand manufacturing ideas and experiences. Danke aims to provide you with a deeper understanding of the processes, best practices, and innovative approaches that have shaped our work in these fields.

Lightweighting and Biodegradability: The Future of Packaging Plastic Injection Molding

The packaging industry is undergoing a major shift, fueled by an increased emphasis on sustainability, cost reduction and enhanced product functionality. Injection molding, renowned for its accuracy and ability to be produced at scale, plays a key...

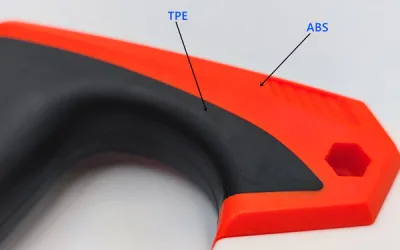

Overmolding in Automotive Control Systems

Overmolding is absolutely critical in automotive control systems, where the fusion of rigid and soft materials directly impacts safety, functionality, durability and user experience. This application moves beyond simple comfort into the realm of...

The Critical Role of CNC Machining in Medical Parts Production: A Synthesis of Precision, Safety, and Innovation

In the highly regulated and life-dependent field of medical manufacturing, the choice of production technology is a critical determinant of success. CNC machining stands as a cornerstone process, offering an unparalleled combination of capabilities...

Vacuum Casting: Applications in Automotive Prototyping and Low-Volume Production

The ability to rapidly iterate designs and bring high-quality components to market more quickly is a critical advantage in the fast-paced and competitive automotive industry. Vacuum casting has emerged as the cornerstone technology to achieve this,...

How Plastic Injection Molding Shapes the Bodies of Modern Consumer Appliances

Look around any modern home - from the kitchen to the laundry room - and you are surrounded by sleek, seamless, durable appliance bodies made possible by plastic injection molding. This manufacturing process is the invisible force behind the form...

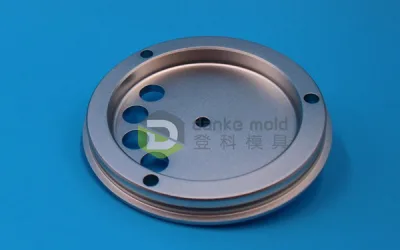

Rapid Tooling: A Guide to Principles, Benefits, and Applications

In today's fast-paced manufacturing landscape, the ability to move quickly from design to final product is a critical competitive advantage. Rapid Tooling has emerged as the cornerstone technology enabling this acceleration, bridging the gap...

Enhancing User Experience: The Critical Role of Overmolding in Consumer Electronics

Overmolding has evolved from a niche manufacturing technique to a fundamental process in consumer electronics. It is the key to creating the tactile, durable and aesthetically pleasing devices that define modern brands. By fusing a rigid plastic...

2-Shot Injection Molding in Medical Devices: Integrating Function, Safety, and Ergonomics

The applications of 2-shot injection molding in the medical industry are broad and critical, as it directly addresses the sector's unique demands for accuracy, safety, patient comfort and cost effectiveness. This process is often the preferred...

Advanced Plastic Injection Molding Techniques for Aerospace Applications

Plastic injection molding has emerged as a vital and rapidly evolving manufacturing method in aerospace. While metals have traditionally dominated the industry, the ongoing need for lighter weight, improved fuel efficiency and integrated components...

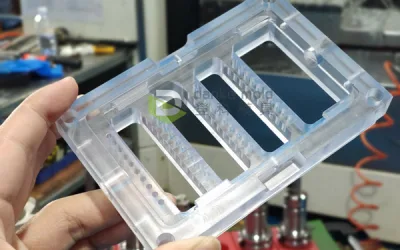

From CAD to Customer: How Vacuum Casting De-Risks Electronics Development

In the hyper-competitive consumer electronics industry, the gap between a digital design and a successful market product is wide. Bridging this gap requires a process that balances speed, cost, and fidelity. Vacuum casting has emerged as a critical...

CNC Machining: Applications and Industries

What is CNC Machining? CNC machining is a subtractive manufacturing process where pre-programmed computer software dictates the movement of factory tools and machinery. A block of material is shaped by removing material with a cutting tool to...

Compression Molding: Manufacturing for Automotive Lightweighting

Compression molding is a prominent manufacturing process used in the automotive industry to achieve lightweighting goals. This method involves placing a preheated thermoset or thermoplastic resin and reinforcing fibers into a heated mold cavity....