Today we are talking about milling machine structure and its working. Milling machine is used to machining the metal and plastic work-piece by revolving cutting tool.It is versatile machine, It can perform all operations like turning, facing, drilling, shaping, grooving, etc. Milling is widely used in manufacturing metal/ plastic prototype and die making industries

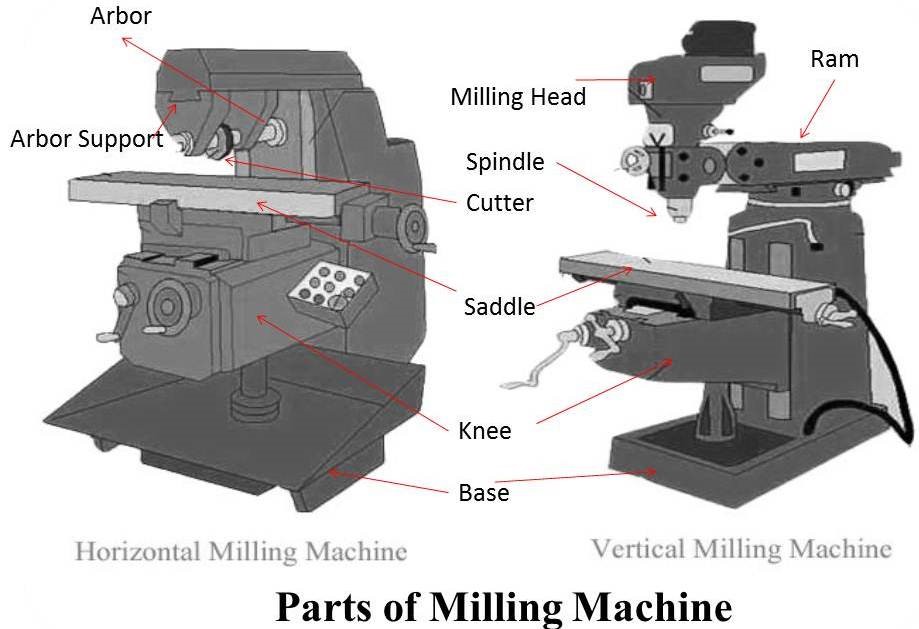

The major components of a typical milling machine include the following: base, column, knee, elevating screw, saddle, machine table, ram, head, and spindle.

The base is the heavy foundation of the machine and can also be used as a reservoir for coolant or cutting lubricant often used in machining operations. The base is a massive casting which helps to absorb and dampen vibration from the machining process.

The Column supports the functioning members of the machine. Horizontal on the top of the column support the ram and head, while vertical on the column front face support the knee, saddle, and machine table.

The knee moves along the vertical ways of the column and is basic work-supporting member. The elevating screw provides additional support for the knee and allows the knee to be raised and lowered.

The saddle mounts on the ways at right angles to the knee ways to support the machine table. The machine table moves longitudinally on the ways of the saddle and supports the work piece.

These components work together to complete something called a 3-axis movement which allows precise positioning and feeding of the work piece left and right, in and out, and up and down.

There are mostly two types of milling machine used in machanical industries, First one is horizontal milling machine and other one is vertical milling machine. See the picture above.

Vertical milling machines are really versatile and are used to machine horizontal surfaces, vertical surfaces, angular surfaces, shoulders, grooves, filets, key way’s, T-slots, dovetails, and precision holes. They have what is called multi-axis which has the capability to tilt the vertical axis and swivel to enable the machining of closed angles and contoured surfaces.

Horizontal milling machines come in plain and universal types. Plain milling has tables which are fixed at right angles to the knee. While universal milling machines have a table which can be pivoted in a horizontal plane. Allowing the machine table to swivel to different angles for milling helical grooves. Rather vertical or horizontal they both prefer to the orientation of the main spindle. Both types range in size from small, bench-mounted devices to room-sized machines.

Unlike a drill press, milling machine move the work piece radically against the rotating milling cutter, while a drill press holds the work piece stationary as the drill moves axially to penetrate the material. Work piece and cutter movement are controlled to less than 0.001 usually by means of precision ground slides and lead screws or analogous technology. These machines may be manually operated, mechanically automated, or digitally automated from a computer, CNC (computer numerical control).

Milling machine is not as “powerful” as CNC machine, but it is easy and convenient to use. It’s very suitable for us to create some small and simple features, just like groove, hole, step……,so it’s very useful for rapid prototyping and some small modification of tooling components.

Click www.dankemold.com to get more information.