In order to improve performance and life of the machine, we should analyze the factors that affect the surface quality of components and relevant solution to be taken.

How surface quality affect the product performance?

- Roughness is a critical factor that affecting the ware resistance of part surface. Normally the smaller the roughness is, the abrasion will be less during actual using, and the life will be longer as well. However, it doesn’t mean the smoother the better, very smooth surface makes it difficult to keep lubrication oil on the surface, so it enlarge the contact area of the part with another part, then it will increase the abrasion, too.

- Corrosion resistance。The rougher the surface is, the worse that component can resist corrosion.

- Fatigue strength. Metal parts usually fatigue because of cold-hop exchange, deformation that caused by any factor or load. The rougher the surface is, the lower that component can resist fatigue.

- Assembly quality. The worse the surface is, the abrasion will be worse during assembly.

The factors that affect surface finish of components.

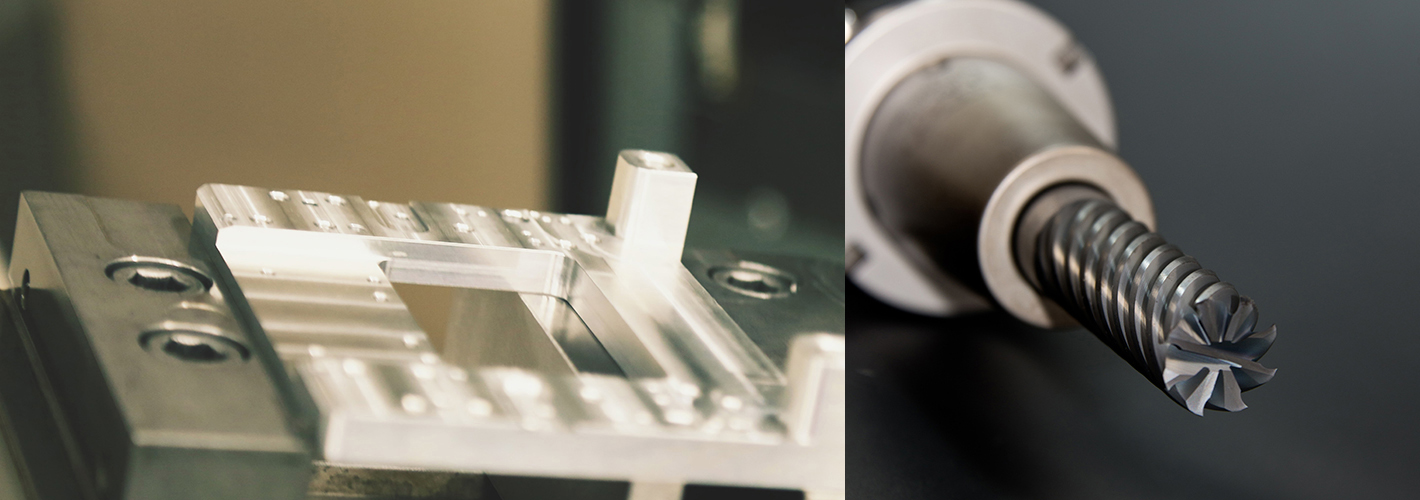

- Milling/cutting method. Reduce the feed of cutter, choose proper cutter, will be good for reducing the residual area of milling layer.

- The properties of material. Normally there are fragility and ductility material. When machining ductility material, it will usually deform because of the squeeze from cutter. For fragility material, since there are much pellets because of cutting, the pellets crash and damage the surface of the part, so make the surface rougher and rougher.

- Grinding. Besides of the speed, hardness of the grinding wheel, the most important factor is the rotating frequency. The cutting force and cutting heat will change the mechanical behavior, include the residual stress, construction and hardness, etc.

How to improve the surface finish of machining?

- Choose the right cutter with smaller chamfer, rounded and bigger radii. This kind of cutter is better for reducing residual area. Never use those cutters that damaged badly, and choose those flat, sharp and completed cutter. So as to avoid the rough surface during machining as possible.

- Use the suitable material. Just like the low carbon steel which is kind of ductility, normalizing and forging should be taken to reduce the ductility before the milling/cutting process. Besides, choose the material with right metallurgical structure is also much better for improving the surface finish.

- Milling/cutting condition. For ductility material, high speed spinning should be taken to reduce the built-up edge which is usually annoying, it can also reduce the feed.

- Machining method. In order to make control the cost the quality, High frequency and high precision machining method should be used, and should reduce radial feed as possible. Choose the wheel with high speed feeding. So as to make the grinding finish loo better.

Both rapid tooling and rapid prototyping like CNC milling/turning, machining surface finish is about product quality, manufacturing efficiency, cost, and even our customer’s feedback. So we have to pay much attention to make it better and better.

Please click www.dankemold.com to get more information.