Plastic injection molding is a manufacturing process used to produce a wide variety of plastic products, from toys to automotive components. Over the years, the industry has seen many innovations and trends that have improved the efficiency and quality of plastic injection molding. In this blog post, we will discuss some of the latest innovations and trends in plastic injection molding.

3D Printing and Prototyping

3D printing has revolutionized the prototyping process in plastic injection molding. With the ability to print 3D models quickly and accurately, manufacturers can create prototypes in a matter of hours instead of days or weeks. This enables manufacturers to test and refine their designs more efficiently, leading to faster time-to-market and cost savings. This is where you would find it offering you a very decent and unique experience in almost every sense of the word.

Multi-Material and Overmolding

Multi-material and Overmolding are techniques that allow manufacturers to combine different materials and colors in a single injection molding process. This has opened up new possibilities for creating complex designs and improving the functionality of plastic parts. For example, Overmolding can be used to create soft-touch grips or to integrate two materials with different properties, such as rigidity and flexibility, in a single part.

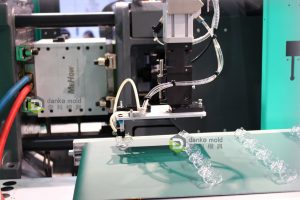

Automation and Robotics

Automation and robotics have transformed the plastic injection molding industry by increasing efficiency, reducing labour costs, and improving quality. Automated systems can handle the entire injection molding process, from material handling to part ejection, with minimal human intervention. Robotics can also be used to perform secondary operations, such as assembly or packaging, further reducing costs and improving efficiency. The robotics has been taking huge impact and the plastic mold making is not an exception either. Most of the modern Plastic Mold Makers today have been focussing on the automation and robotics.

Sustainable Materials

Sustainable materials are becoming increasingly popular in the plastic injection molding industry as consumers and manufacturers alike prioritize environmental responsibility. Biodegradable and compostable plastics are being developed and used to create products that are more environmentally friendly. Additionally, recycled materials can be used in the injection molding process, reducing waste and conserving resources. Use of sustainable materials can be helpful in reducing the environmental impact of any nature. Stand with nature with the choice of the best plastic molders.

Smart Manufacturing and Industry 4.0

Smart manufacturing and Industry 4.0 are trends that are transforming the manufacturing industry as a whole, and plastic injection molding is no exception. By using sensors and data analytics, manufacturers can optimize their processes and improve efficiency, quality, and consistency. Real-time monitoring of production processes can also identify potential issues and allow for quick adjustments, reducing waste and downtime.

Conclusion

Innovation and trends in plastic injection molding are driving the industry forward, improving efficiency, quality, and sustainability. The integration of technologies such as 3D printing, automation and robotics, and smart manufacturing is leading to faster, more cost-effective, and more sustainable production. As the industry continues to evolve, we can expect to see even more advancements in the years to come.