Manufacturing has reached a turning point. Traditional CNC machining methods are joining forces with artificial intelligence to produce parts that meet demanding quality standards. This fusion creates manufacturing processes that adapt, learn, and improve with each production run.

Smart Algorithms Transform CNC Machining Tool Path Optimization

AI algorithms analyze thousands of cutting scenarios to determine optimal tool paths. These smart systems consider material properties, tool wear patterns, and machine capabilities before creating cutting instructions.

Your CNC machining operations benefit from reduced cycle times and improved surface finishes. The AI evaluates multiple path options simultaneously, selecting routes that minimize vibration and extend tool life.

Traditional programming required extensive manual input and testing. AI-driven systems generate optimized paths automatically, reducing programming time from hours to minutes.

Key benefits include:

- Faster spindle speeds with maintained precision

- Reduced tool changes during production

- Lower heat generation during cutting

- Improved dimensional accuracy across all parts

Predictive Analytics Prevent Material Stress Before Production Begins

AI systems analyze material stress patterns before you start cutting. These predictive models examine part geometry, material composition, and cutting forces to identify potential failure points.

The technology prevents costly mistakes by flagging problematic areas in your design. You receive warnings about thin walls, sharp corners, or features that might cause warping during production.

Material stress prediction saves both time and money. Instead of discovering problems during production, you address issues during the planning phase.

Smart algorithms calculate optimal clamping forces and cutting parameters. They determine the best approach for each material type and part geometry.

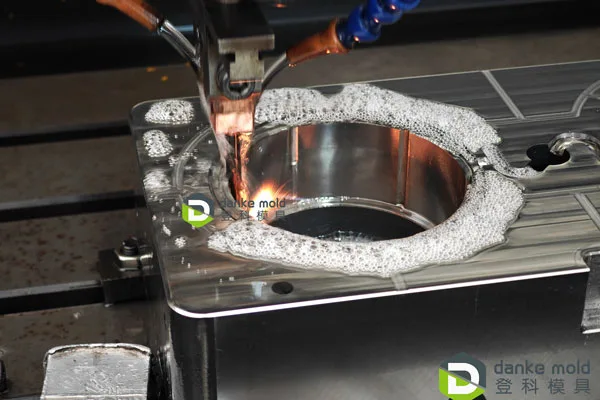

CNC machine tool processing

Real-Time Defect Detection Creates Zero-Error Production Environments

CNC machining systems equipped with AI sensors monitor every aspect of the production process. These systems detect dimensional variations, surface irregularities, and tool wear in real-time.

Your production stops automatically when sensors identify potential defects. This immediate response prevents the creation of defective parts and reduces material waste.

Machine learning algorithms improve detection accuracy over time. They learn to distinguish between normal variations and actual defects, reducing false alarms.

The technology tracks patterns across multiple production runs. You gain insights into recurring issues and can implement preventive measures.

Detection capabilities include:

- Surface finish variations

- Dimensional deviations beyond tolerance

- Tool breakage or excessive wear

- Vibration patterns indicate problems.

Adaptive Learning Systems Improve Manufacturing Performance Continuously

AI-powered CNC machining systems learn from every production cycle. They analyze cutting data, tool performance, and part quality to refine future operations.

Your machines become smarter with each job they complete. The AI identifies successful cutting strategies and automatically applies them to similar parts.

These learning systems reduce setup time for repeat orders. They recall optimal settings and apply them instantly, eliminating the need for trial-and-error approaches.

Performance improvements compound over time. What starts as small gains in speed and quality becomes a significant competitive advantage.

The technology adapts to changing conditions without human intervention. Temperature fluctuations, tool wear, and material variations are automatically compensated.

Smart Manufacturing Delivers Measurable Business Results

AI integration transforms CNC machining from a reactive to a proactive manufacturing process. You gain predictable outcomes, reduced waste, and faster delivery times.

Production scheduling becomes more accurate when AI systems provide realistic time estimates. You can commit to delivery dates with confidence, knowing your smart machines will meet expectations.

Quality consistency improves dramatically across all production runs. AI ensures that every part meets specifications, regardless of the operator’s experience or external conditions.

The combination of artificial intelligence and precision machining creates manufacturing capabilities that were previously considered impossible just a few years ago. Your production facility becomes a smart factory that adapts, learns, and delivers exceptional results.

Ready to transform your manufacturing operations with AI-powered precision? Danke mold combines advanced CNC machining capabilities with cutting-edge technology to deliver flawless parts for your most demanding projects.