by Danke Mold | Jan 16, 2026 | Over Molding

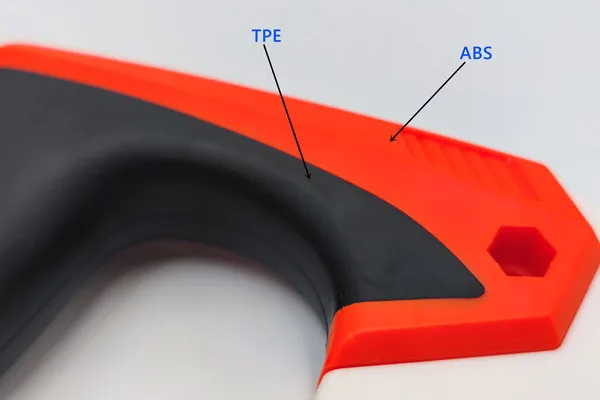

In the world of hand tools, performance is often measured at the point of contact: the sharpness of a blade, the hardness of a wrench jaw, or the precision of a screwdriver tip. Yet for the humble screwdriver, a tool defined by its ability to transfer human force to...

by Danke Mold | Dec 26, 2025 | Over Molding

Overmolding cable assemblies have become a cornerstone of modern electrical and electronic systems, offering enhanced durability, environmental protection and streamlined design. From consumer electronics to industrial machinery, overmolding cables are vital for...

by Danke Mold | Dec 9, 2025 | Over Molding

Overmolding in packaging transforms utilitarian containers into premium, functional, and user-friendly products. It’s a key differentiator in competitive markets, adding tangible value through enhanced ergonomics, sealing, and brand perception. Core Drivers for...

by Danke Mold | Nov 26, 2025 | Over Molding

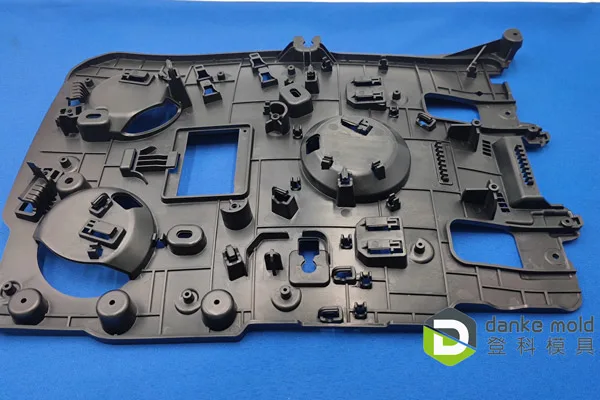

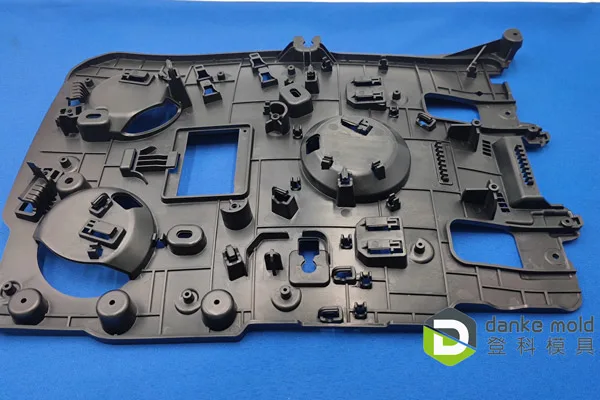

Overmolding is absolutely critical in automotive control systems, where the fusion of rigid and soft materials directly impacts safety, functionality, durability and user experience. This application moves beyond simple comfort into the realm of precise human-machine...

by Danke Mold | Nov 11, 2025 | Over Molding

Overmolding has evolved from a niche manufacturing technique to a fundamental process in consumer electronics. It is the key to creating the tactile, durable and aesthetically pleasing devices that define modern brands. By fusing a rigid plastic substrate with a soft...

by Danke Mold | Oct 21, 2025 | Over Molding

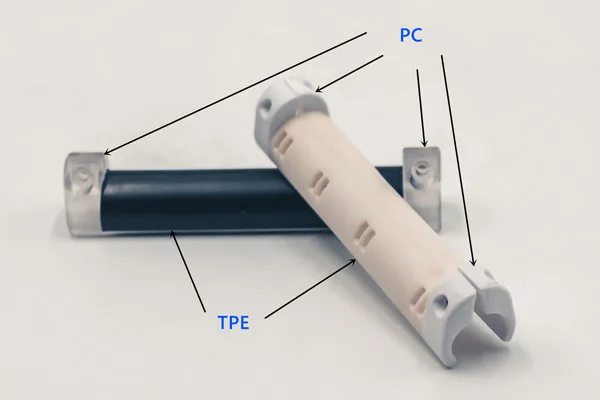

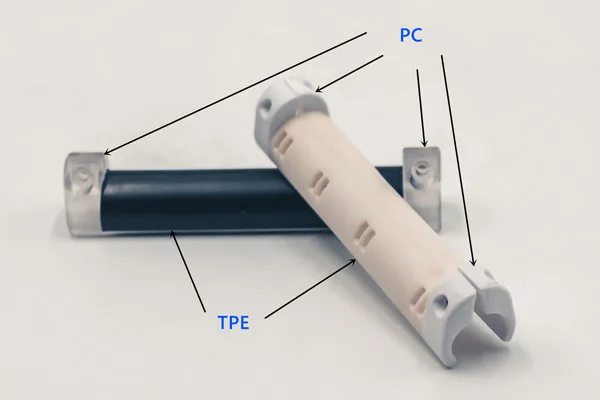

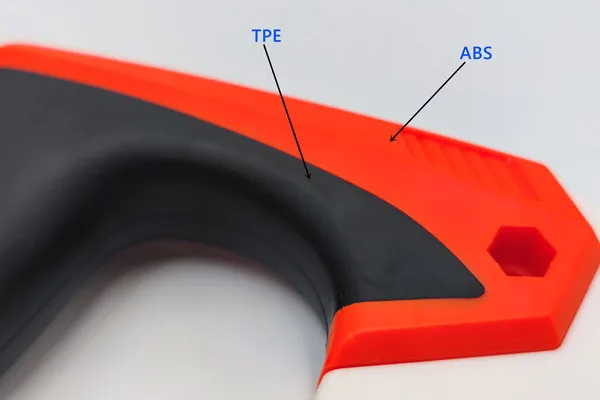

In many industries, products often require distinct core and surface characteristics – something that a single material alone cannot provide. To meet this demand, manufacturers employ a technique called over-molding, in which one material is layered on top of...