by Danke Mold | Oct 27, 2025 | Compression Molding

Compression molding is a prominent manufacturing process used in the automotive industry to achieve lightweighting goals. This method involves placing a preheated thermoset or thermoplastic resin and reinforcing fibers into a heated mold cavity. The mold is then...

by Danke Mold | Oct 25, 2025 | 2-Shot Injection Molding

In the highly competitive consumer electronics market, 2-Shot Injection Molding is a critical manufacturing process that allows brands to create products with superior aesthetics, enhanced user experience and robust functionality. This is the technology behind the...

by Danke Mold | Oct 21, 2025 | Over Molding

In many industries, products often require distinct core and surface characteristics – something that a single material alone cannot provide. To meet this demand, manufacturers employ a technique called over-molding, in which one material is layered on top of...

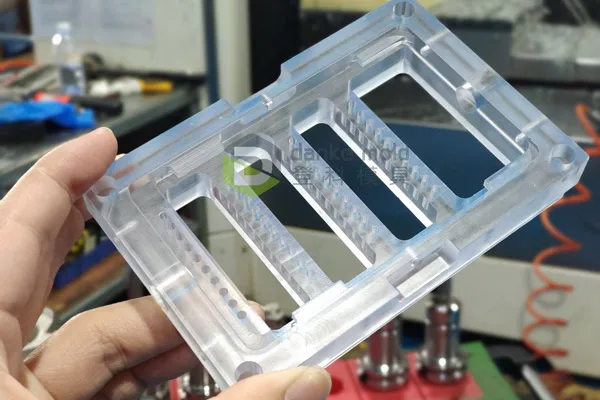

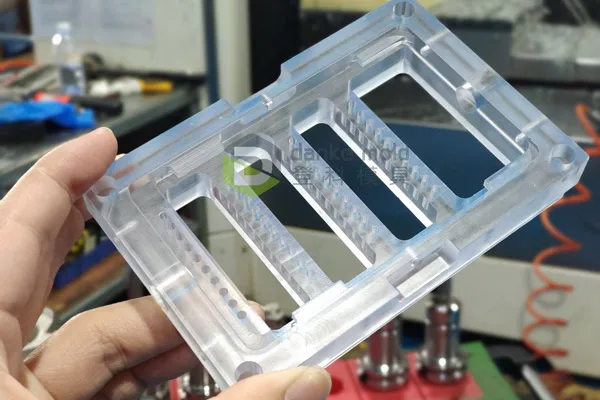

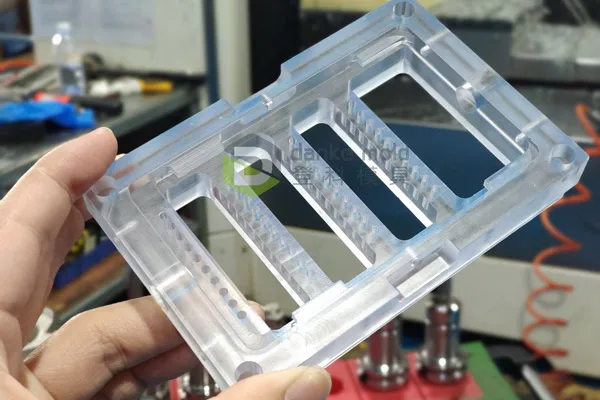

by Danke Mold | Oct 17, 2025 | Insert Molding

What is Insert Molding? Insert molding is a specialized injection molding process where a pre-formed component (the “insert”) is placed into a mold cavity. The molten plastic is then injected into the mold, where it flows around, over, or through the...

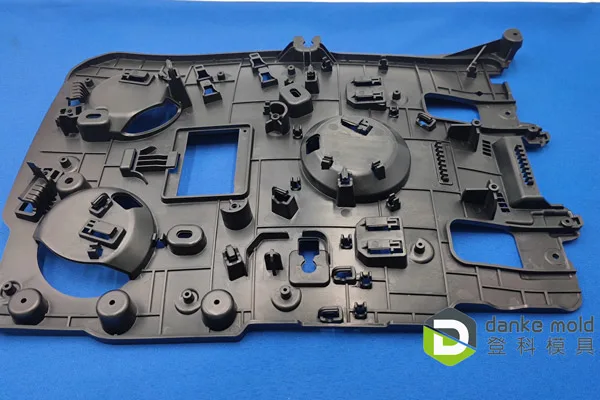

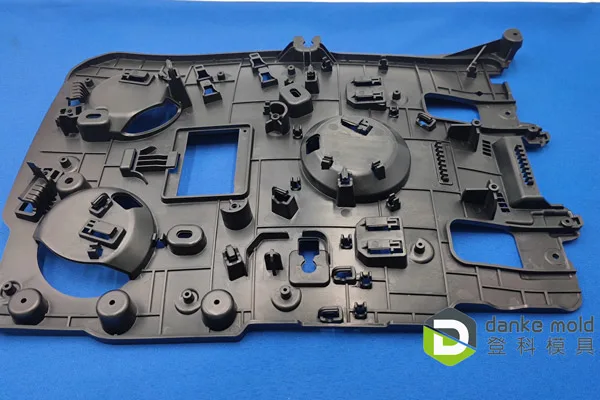

by Danke Mold | Oct 14, 2025 | Plastic Injection Molding

Plastic injection molding has become an indispensable manufacturing process in the automotive industry, revolutionizing how vehicles are designed, built and executed. This technology enables the production of high-quality, durable, complex components that meet the...