by Danke Mold | Feb 22, 2026 | Plastic Injection Molding

The plastic injection molding industry has long been a cornerstone of manufacturing, enabling the mass production of countless everyday items—from automotive parts and consumer electronics to medical devices and packaging. As global concerns about environmental...

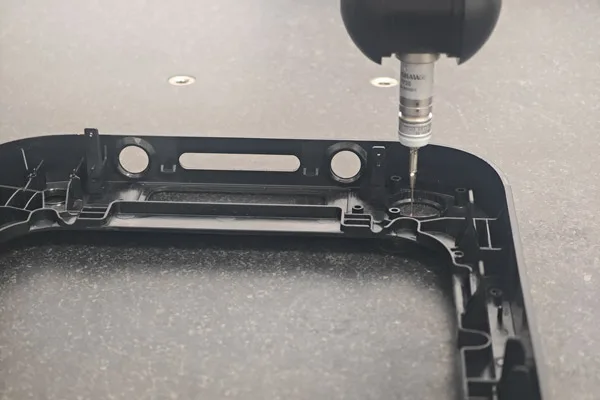

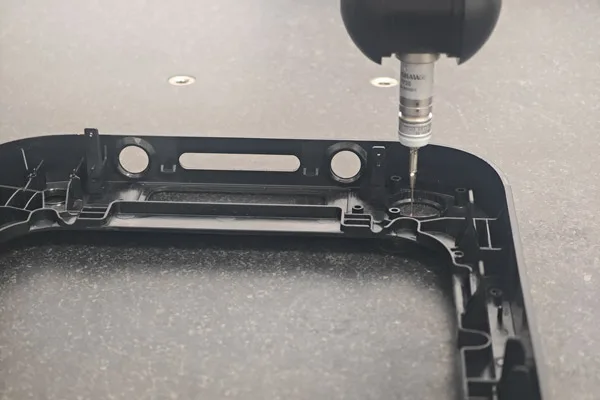

by Danke Mold | Feb 18, 2026 | Vacuum Casting

The prototyping phase is a critical juncture in the race to bring a product to market. This is where ideas are physically validated, designs are tested, and stakeholders are convinced. While technologies such as 3D printing have revolutionized speed and traditional...

by Danke Mold | Feb 15, 2026 | Compression Molding

Compression molding is a highly versatile and efficient manufacturing process widely used in industries such as aerospace, automotive, electronics and consumer goods. It involves placing a pre-measured amount of a material – often a thermoset resin,...

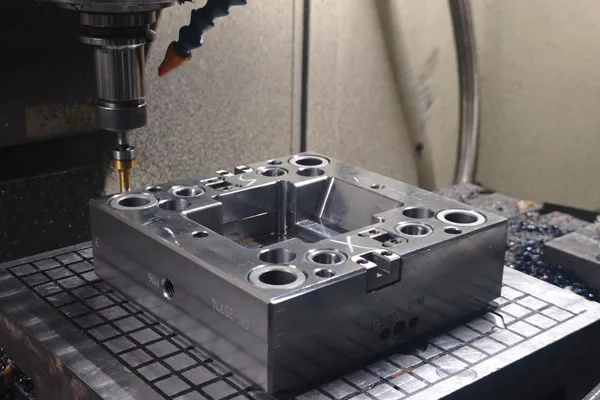

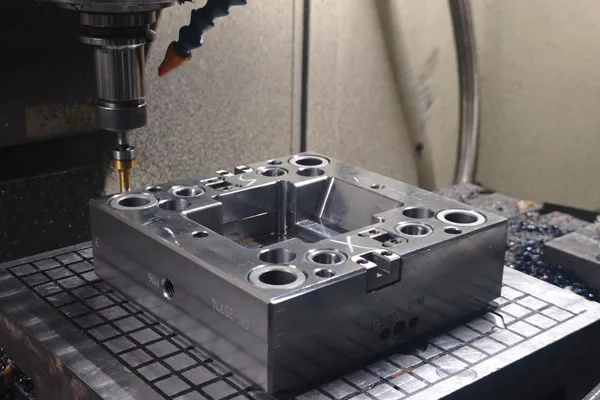

by Danke Mold | Feb 10, 2026 | CNC Machining

In the competitive arena of product development, speed, accuracy and flexibility are paramount. Rapid prototyping bridges the gap between digital design and physical reality, allowing engineers to validate, test and refine their ideas with tangible parts. While...

by Danke Mold | Feb 6, 2026 | Plastic Injection Molding

Plastic injection molding is a manufacturing process that has revolutionized the way industries produce a wide array of products. From everyday household items to complex automotive components, this technique offers unparalleled advantages, making it the choice of...