by Danke Mold | Aug 28, 2025 | Plastic Injection Molding

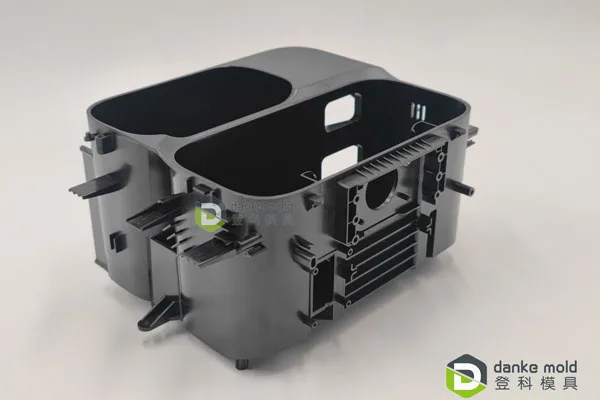

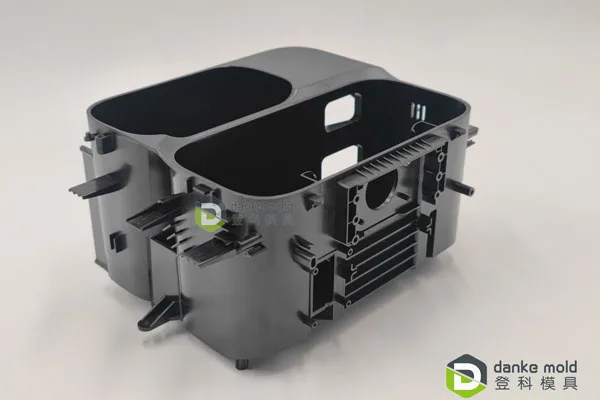

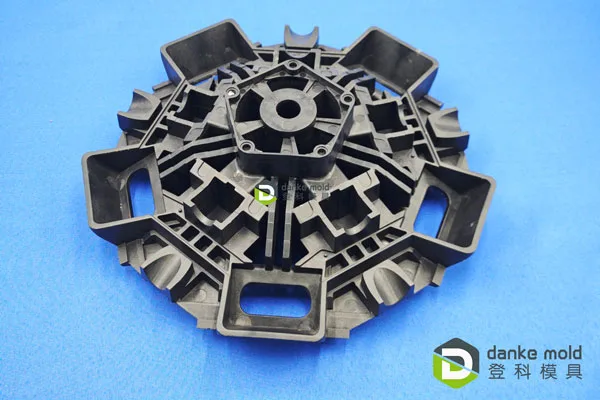

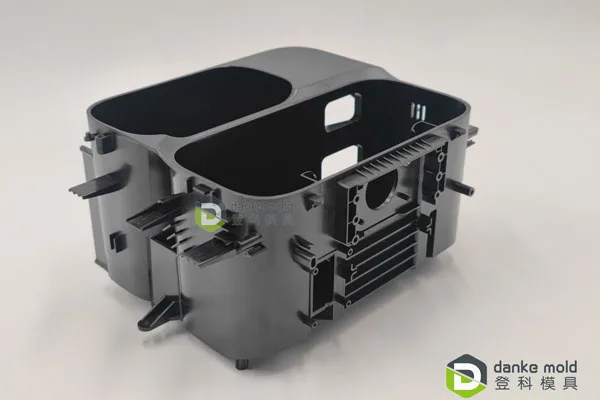

Injection molding stands as the gold standard for high-volume plastic part production, dominating industries that require millions of identical components with precision and efficiency. Its ability to produce complex, high-tolerance parts at unmatched speed makes it...

by Danke Mold | Aug 25, 2025 | Plastic Injection Molding

Chemical storage demands have pushed manufacturing technology beyond traditional single-layer containers. Multi-layer blow molding technology combines different plastic materials into a single drum, creating superior chemical resistance and barrier properties that...

by Danke Mold | Aug 22, 2025 | Plastic Injection Molding

When producing disposable lab equipment, maintaining sterility while meeting high demand is critical. Plastic injection molding allows you to manufacture precise, sterile components at scale, ensuring each piece meets strict healthcare standards. This process...

by Danke Mold | Aug 18, 2025 | Rapid Prototyping

Launching a new vehicle concept often means battling long development cycles and high costs. With rapid prototyping, you can significantly reduce timelines by transitioning from design to functional parts in days rather than weeks. This approach can minimize R&D...

by Danke Mold | Aug 16, 2025 | Rapid Tooling

Heavy machinery downtime costs industrial operations thousands of dollars per hour, yet traditional spare parts procurement often requires weeks or months of lead time. When critical equipment fails and replacement parts are unavailable, production grinds to a halt...