Plastic injection molding is a manufacturing process that has revolutionized the way industries produce a wide array of products. From everyday household items to complex automotive components, this technique offers unparalleled advantages, making it the choice of choice for manufacturers worldwide. As businesses seek efficient, cost-effective and high-quality production methods, understanding the key benefits of plastic injection molding becomes essential. In this comprehensive article, we will explore the various advantages that make plastic injection molding a valuable process in modern manufacturing.

Cost-Effectiveness for High-Volume Production

One of the most significant benefits of plastic injection molding is its cost efficiency, especially when produced in large quantities. After the initial investment in mold creation, the per-unit cost drops dramatically. This economy of scale makes injection molding highly suitable for mass production, where thousands or even millions of parts are required. Rapid cycle times further enhance cost savings, enabling manufacturers to meet tight deadlines and large order volumes efficiently.

High Precision and Consistency

Injection molding offers exceptional precision and repeatability. Modern molds are manufactured with sophisticated CNC machining and EDM (Electrical Discharge Machining), ensuring tight tolerances and intricate detailing. Once a mold is designed and fabricated, each part produced is virtually identical, guaranteeing consistency across production runs. This high level of precision is crucial for industries such as aerospace, medical devices, and electronics, where exact specifications are mandatory.

Design Flexibility and Complexity

The process allows for the creation of complex geometries that would be difficult or impossible with other manufacturing methods. Features such as undercuts, threads, ribs, and intricate surface textures can be integrated into the mold design. This flexibility in design helps in consolidating multiple parts into a single component, reducing assembly costs and improving product reliability.

Material Versatility

A wide variety of thermoplastics, thermosets and elastomers are available for injection molding, including ABS, polycarbonate, nylon, polypropylene and many more. This material diversity allows manufacturers to select optimal properties for their specific applications, such as strength, flexibility, heat resistance, or chemical resistance. Additionally, advancements in composite and bio-based plastics expand the scope of injection molding into new markets.

Excellent Surface Finish and Aesthetic Appeal

Injection-molded parts typically exhibit smooth surfaces with excellent aesthetic qualities. Fine details, textures and logos can be incorporated directly into the die, reducing the need for secondary finishing processes. This capability allows brands to produce visually appealing products with high-quality surface finishes, enhancing their market appeal.

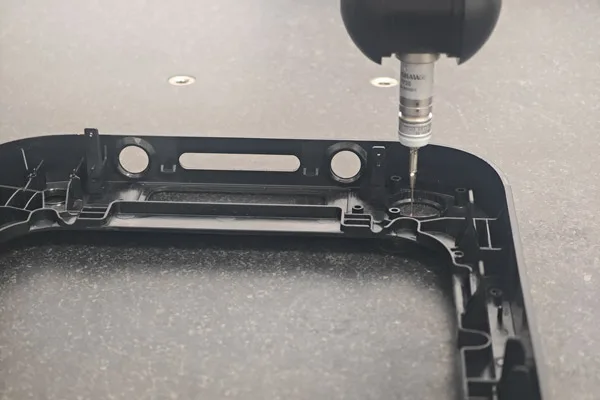

Plastic mold inspection

Reduced Waste and Material Efficiency

Compared to other manufacturing methods like machining or casting, injection molding generates less waste material. Excess plastic, known as sprues, runners, and gates, can often be recycled and reused in subsequent production cycles. This efficiency not only reduces material costs but also aligns with sustainable manufacturing practices.

Faster Production Cycles

The cycle time for injection molding can be as short as a few seconds to a few minutes, depending on part complexity and material. This rapid turnaround enables quick prototyping and fast iteration during product development. Once the design is finalized, large volumes can be produced swiftly, shortening time-to-market.

Scalability and Automation

Injection molding lends itself well to automation, allowing continuous, high volume production with minimal human intervention. Automated systems can handle loading, molding and ejection processes, increasing throughput and reducing labor costs. This scalability makes injection molding suitable for both small and large manufacturing operations.

Durability and Strength of Parts

Plastic parts produced through injection molding are known for their durability and strength. Proper material selection and precise molding conditions result in parts that can withstand mechanical stresses, temperature variations and chemical exposure. This reliability is vital for applications in automotive, consumer electronics, and industrial equipment.

Support for Customization and Innovation

Injection molding supports customization, allowing manufacturers to produce bespoke parts tailored to specific customer needs. The process also encourages innovation, as designers can experiment with complex geometries, integrated features and advanced materials to develop cutting-edge products.

Conclusion

Plastic injection molding stands out as a highly efficient, versatile and cost-effective manufacturing process that unlocks significant value for industries worldwide. Its ability to produce high-precision, complex and durable components on a large scale makes it indispensable in today’s competitive market landscape. By leveraging the key benefits of injection molding – such as design flexibility, material versatility, and rapid production cycles – businesses can innovate faster, reduce costs, and deliver superior products to their customers. As technology continues to evolve, the scope and capabilities of plastic injection molding are poised to expand even further, cementing its role as a cornerstone of modern manufacturing.