Volume manufacturing appears straightforward on paper. You calculate material costs, labor expenses, and overhead. The final price seems reasonable. Yet many companies have discovered that their actual volume manufacturing costs far exceed initial projections.

These hidden expenses can destroy profit margins and derail entire product launches. Understanding where these costs originate helps you make better decisions for your manufacturing projects. Smart planning prevents costly surprises that plague unprepared companies.

Quality Control Expenses That Plague Volume Manufacturing Operations

Volume manufacturing demands rigorous quality control systems that many companies underestimate. Your initial cost calculations likely focus on production labor and materials. Quality control represents a separate expense category that grows with production scale.

Testing equipment costs multiply rapidly in volume manufacturing environments. Each production line requires dedicated inspection tools, measuring devices, and calibration systems, which need regular maintenance and periodic replacement.

Quality personnel expenses often surprise manufacturing managers. Volume manufacturing requires dedicated quality inspectors, supervisors, and engineers. Their salaries, benefits, and training costs add substantial overhead to your production budget.

Rejected parts create immediate financial losses in volume manufacturing. Every defective unit represents wasted materials, labor time, and machine capacity. The cost compounds when defects occur late in the production process.

Key quality-related expenses include:

- Inspection equipment and calibration services

- Quality control personnel salaries and training

- Scrap material disposal and recycling costs

- Rework labor for defective products

- Customer returns and warranty claims

- Third-party certification and testing fees

Setup and Tooling Costs That Impact Volume Manufacturing Budgets

Volume manufacturing requires specialized tooling and equipment setup that creates significant upfront investments. Your production planning must account for these costs spread across expected production volumes. Underestimating tooling expenses leads to budget overruns.

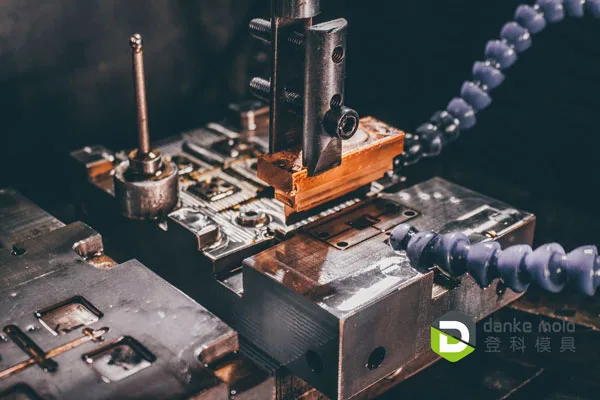

Die, and mold costs scale dramatically with complexity in volume manufacturing. Custom tooling for complex parts can cost hundreds of thousands of dollars. These tools require regular maintenance and eventual replacement during long production runs.

Machine setup time converts directly to labor costs in Volume manufacturing operations. Skilled technicians spend hours configuring equipment for each new production run, and their time costs money that must be factored into per-unit pricing.

Prototype development and testing add substantial costs before volume manufacturing begins. Multiple design iterations require new tooling or modifications to existing equipment, and these development costs often exceed initial estimates.

Storage and handling equipment represent another hidden expense category. You require specialized storage systems, material handling equipment, and inventory management tools in volume manufacturing.

Mould processing

Supply Chain Disruptions and Their Financial Impact on Volume Manufacturing

Raw material price fluctuations create ongoing cost pressures in volume manufacturing. Your initial pricing assumes stable material costs. Market volatility can destroy profit margins when contracts lock in selling prices.

Supplier qualification and backup planning require substantial investments. Volume manufacturing depends on reliable suppliers who consistently meet quality standards. Developing and maintaining these relationships costs time and money.

Transportation and logistics expenses grow with production scale. Volume manufacturing generates large shipments that require specialized handling and routing. Fuel costs, shipping insurance, and freight delays impact your bottom line.

Inventory carrying costs accumulate rapidly in volume manufacturing. Raw materials, work-in-process inventory, and finished goods take up storage space, and we have to manage them, which is a cost overhead. We see this cost grow over time.

In addition, supply chain risk management adds another layer of expense. In volume manufacturing, we put in place contingency plans, identify backup suppliers, and maintain safety stock, all of which cost money. However, they prevent production breaks, which, on a large scale, can bring down the entire system.

Labor and Overhead Expenses That Escalate During Volume Manufacturing

Direct labor costs represent only part of the total workforce expense in volume manufacturing. Indirect labor, supervision, and support staff create substantial overhead that many companies overlook during planning phases.

Training and certification programs require ongoing investment in volume manufacturing operations. Workers need continuous education on new processes, safety procedures, and quality standards; training costs never disappear.

Employee turnover creates hidden recruitment and training expenses. Volume manufacturing often involves repetitive work that leads to higher turnover rates. Replacing and training new workers costs time and money.

Facility costs scale with production volume but not proportionally. Volume manufacturing requires larger spaces, specialized utilities, and enhanced safety systems. These fixed costs must be spread across production units.

Maintenance and repair expenses grow with equipment utilization. Volume manufacturing pushes machines to capacity limits, increasing wear and breakdown frequency. Preventive maintenance programs cost money but prevent costlier emergency repairs.

Strategies to Control Hidden Costs in Volume Manufacturing

Cost tracking systems help identify where expenses exceed projections. Volume manufacturing generates complex cost structures that require detailed monitoring. Regular cost analysis reveals trends before they become problems.

Supplier partnerships reduce many hidden costs through collaborative planning. Working closely with key suppliers creates opportunities for cost reduction and quality improvement. Long-term relationships provide stability in volume manufacturing operations.

Automation investments often pay for themselves through reduced labor costs and improved quality. Volume manufacturing benefits from consistent automated processes that eliminate human error and minimize workforce requirements.

Process standardization reduces setup costs and improves quality consistency. Volume manufacturing thrives on repeatable processes that minimize variation and waste. Standard procedures reduce training time and improve outcomes.

Risk management planning prevents costly disruptions. Volume manufacturing requires contingency plans for supply chain problems, quality issues, and equipment failures. Preparation costs less than crisis response.

Volume manufacturing success depends on understanding and controlling hidden costs. Your profit margins depend on accurate cost accounting that includes all expense categories. Smart planning and continuous monitoring of your manufacturing processes will ensure you keep an eye on unexpected expenses.

For reliable volume manufacturing, which also involves controlling those hidden costs you’re looking for, we at Danke Mold have the expert outsourcing solutions you require.