Heavy machinery downtime costs industrial operations thousands of dollars per hour, yet traditional spare parts procurement often requires weeks or months of lead time. When critical equipment fails and replacement parts are unavailable, production grinds to a halt while companies wait for custom manufacturing or supplier deliveries.

Rapid tooling offers a revolutionary solution by enabling on-demand production of spare parts directly at your facility or through local manufacturing partners, dramatically reducing downtime from weeks to days. This streamlined manufacturing approach uses advanced techniques to quickly create the molds and tooling needed for producing functional replacement components.

You can now maintain equipment more effectively by producing spare parts as needed rather than maintaining extensive inventory or relying on lengthy supply chains. This transformation in maintenance strategy allows you to optimize both equipment availability and production costs while ensuring your heavy machinery remains operational when you need it most.

The Role of Rapid Tooling in On-Demand Spare Parts for Heavy Machinery

Rapid tooling transforms how heavy machinery operators manage component replacement by enabling quick mold creation and reducing lead times from months to days. This technology addresses critical downtime challenges while providing cost-effective solutions for low-volume spare parts production.

Rapid Tooling Technology Overview

Rapid tooling uses advanced manufacturing techniques to create molds and dies in significantly shorter timeframes than traditional methods. You can produce functional tooling within days rather than the typical months required for conventional machining.

The process relies on technologies like 3D printing, CNC machining, and hybrid approaches to build production-ready tools. Metal 3D printing has become particularly valuable for creating complex geometries that traditional methods cannot achieve efficiently.

Your tooling options include both direct and indirect approaches. Direct rapid tooling creates the final production tool using additive manufacturing. Indirect methods use rapid prototyping to develop patterns for casting conventional tools.

Modern rapid tooling supports various materials, including aluminum, steel, and specialized alloys suitable for heavy machinery applications. These materials withstand the pressures and temperatures required for producing durable spare parts.

Advantages for Heavy Machinery Components

Reduced downtime represents the most critical benefit for heavy machinery operations. When equipment fails, you can obtain replacement parts within days instead of waiting weeks or months for traditional tooling processes.

Cost savings become substantial for low-volume spare parts production. You eliminate the need for expensive traditional tooling when producing small quantities of specialized components that heavy machinery requires.

Rapid tooling spare parts offer design flexibility that traditional methods cannot match. You can modify part designs quickly based on field performance or incorporate improvements without significant retooling costs.

Quality validation happens faster through rapid iteration cycles. You can test multiple design variations and material combinations before committing to large production runs.

Inventory management improves dramatically since you produce parts on demand rather than maintaining large stockpiles of slow-moving spare parts components.

On-Demand Parts Manufacturing Process

Your on-demand parts manufacturing begins with digital part libraries containing CAD files for all heavy machinery components. These databases enable immediate access to part specifications when replacements are needed.

The production workflow follows these steps:

- Part identification and specification retrieval

- Rapid tool design and optimization for the specific component

- Tool manufacturing using appropriate rapid tooling methods

- Parts production and quality verification

- Delivery to the equipment location

Lead times typically range from 3-10 days, depending on component complexity and material requirements. This timeline includes tool creation, part production, and shipping.

On-demand parts manufacturing eliminates the minimum order quantities that traditional suppliers often require. You can produce single components or small batches as needed for maintenance operations.

Digital integration allows you to track parts usage patterns and predict future needs. This data helps optimize inventory levels and identify opportunities for design improvements in heavy machinery components.

Optimizing Equipment Maintenance and Production with Rapid Tooling

Rapid tooling transforms heavy machinery maintenance by delivering critical components faster and more cost-effectively than traditional manufacturing methods. This approach enables manufacturers to produce aluminum and steel molds quickly for replacement parts while maintaining production schedules.

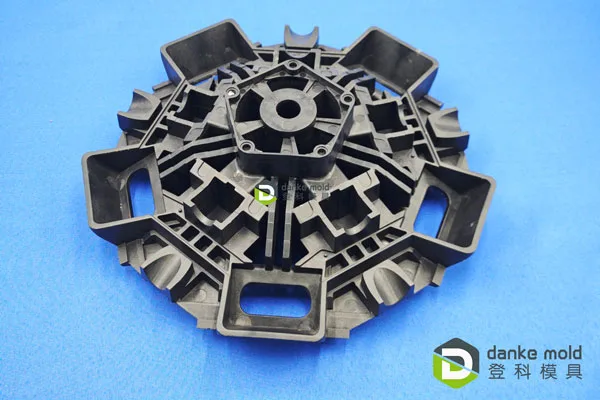

Injection molded parts

Fast Turnaround Tooling for Downtime Reduction

Equipment failures create expensive production delays that can cost thousands per hour. Fast turnaround tooling addresses this challenge by producing replacement components in days rather than weeks.

Rapid tooling uses streamlined mold creation processes to manufacture critical spare parts on demand. You can obtain functional replacement components within 5-10 business days compared to 6-8 weeks with conventional tooling methods.

Key advantages of fast turnaround approaches:

- Reduced inventory storage costs

- Minimized equipment downtime

- Immediate response to unexpected failures

- Lower emergency procurement expenses

Aluminum molds enable the quick production of plastic components like covers, gaskets, and housing parts. Steel tooling handles more demanding applications requiring metal replacement parts with precise tolerances.

Bridge Tooling Solutions for Industrial Spare Part Production

Bridge tooling serves as an interim solution between prototype development and full-scale production tooling. This method proves particularly valuable for spare parts with uncertain demand patterns.

You can produce 500-5000 parts using bridge tooling before transitioning to production-grade molds. This approach validates part performance while meeting immediate supply needs without significant capital investment.

Bridge tooling applications include:

- Seasonal spare parts with fluctuating demand

- Legacy equipment components with discontinued supplier support

- New equipment launches requiring initial spare part inventory

- Testing alternative materials before committing to production tooling

The process uses durable aluminum or mild steel molds that withstand moderate production volumes. These tools cost significantly less than hardened steel production molds while delivering acceptable part quality and dimensional accuracy.

Low-Volume Replacement Parts Strategies

Manufacturing low-volume replacement parts presents unique challenges due to high per-unit tooling costs. Rapid tooling makes small-batch production economically viable through reduced upfront investment and faster delivery times.

You can implement just-in-time spare parts strategies using rapid tooling methods. This eliminates the need for extensive inventory while ensuring critical components remain available when needed.

Effective low-volume strategies:

- On-demand production triggered by actual orders

- Regional tooling centers for faster local delivery

- Digital part libraries enabling rapid mold recreation

- Flexible manufacturing partnerships

Consider rapid tooling for parts requiring fewer than 10,000 units annually. The break-even point typically favors rapid methods when comparing total cost, including inventory, storage, and obsolescence factors.