Injection molding stands as the gold standard for high-volume plastic part production, dominating industries that require millions of identical components with precision and efficiency. Its ability to produce complex, high-tolerance parts at unmatched speed makes it the go-to choice for mass manufacturing.

What Is Plastic Injection Molding?

Plastic injection molding is a manufacturing process where molten plastic is injected into a mold cavity under high pressure. Once cooled and solidified, the part is ejected, resulting in a finished plastic component.

Key Steps in Injection Molding:

1. Clamping – The mold is securely closed by a hydraulic or mechanical press.

2. Injection – Molten plastic is injected into the mold cavity.

3. Cooling – The plastic solidifies inside the mold.

4. Ejection – The finished part is ejected, and the cycle repeats.

Common Injection Molding Materials

Selecting the right plastic material is critical to the performance of the part. The following are the most commonly used thermoplastics:

|

Material |

Key Properties |

Applications |

| Polypropylene (PP) | Chemical-resistant, flexible, low-cost | Food containers, automotive parts |

| ABS | Tough, impact-resistant, machinable | Toys, electronics, car interiors |

| Polycarbonate (PC) | High strength, transparent, heat-resistant | Bulletproof glass, medical devices |

| Nylon (PA) | Wear-resistant, strong, heat-resistant | Gears, bearings, industrial parts |

| Acrylic (PMMA) | Crystal clear, UV-resistant, scratch-resistant | Displays, lenses, signs |

| Polyethylene (PE) | Lightweight, moisture-resistant | Bottles, bags, pipes |

Design Considerations for Injection Molding

To ensure manufacturability and reduce defects, follow these guidelines:

Wall Thickness

Optimal Range: 1.5mm – 4mm

Avoid very thick walls (causes sink marks) or very thin walls (leads to incomplete filling).

Draft Angles

Recommended: 1° – 2° per side for easy ejection.

Ribs and Bosses

Ribs should be 50-60% of the main wall thickness.

Bosses (for screws/inserts) should have sufficient support to avoid cracking.

Undercuts and Textures

Undercuts require side-action molds.

Textured surfaces help hide flow lines and ejection marks.

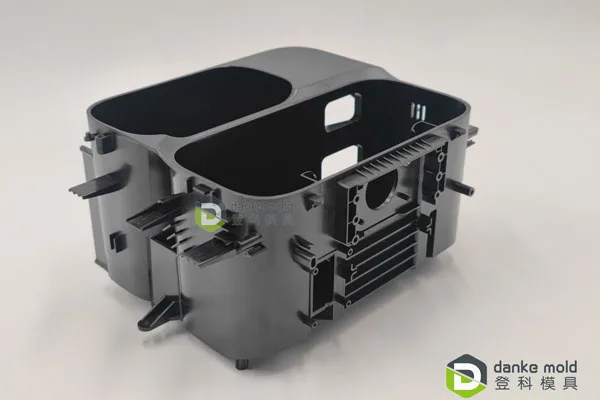

Plastic parts

Common Defects and How to Avoid Them

|

Defect |

Cause |

Solution |

| Sink Marks | Uneven cooling, thick walls | Adjust cooling time, reduce thickness |

| Warping | Non-uniform cooling | Optimize mold temperature and design |

| Flash | Excess material leaks from mold | Increase clamping force, check mold fit |

| Short Shots | Insufficient material injection | Increase injection pressure/speed |

Advantages of plastic injection molding

- High production speed

- Low labor costs after initial setup

- Excellent repeatability & tight tolerances

- Wide range of material options

Conclusion

Plastic injection molding is a highly efficient manufacturing method for mass producing plastic parts with high accuracy. By choosing the right materials, optimizing the design and avoiding common defects, manufacturers can achieve high-quality, cost-effective production.