Dual-material overmolding technology enables the combination of two different materials into a single part through the injection molding process. This process enhances the functionality and aesthetic of your products by molding a softer or contrasting material over a rigid substrate in one or multiple steps. The key advantage of dual-material overmolding is that it creates durable, multi-functional components without requiring additional assembly.

With injection molding, you can achieve precise control over the bonding between materials, which improves product performance in applications ranging from consumer goods to electronics. This technology also allows you to experiment with different textures, colors, and mechanical properties, all within a streamlined production cycle.

Understanding how dual-material injection molding works can help you choose the right method and materials for your project. Whether you need enhanced grip, cushioning, or part integration, this technique provides versatile solutions that meet the demands of modern manufacturing.

Core Principles of Dual-Material Overmolding Tech

Dual-material overmolding requires precise control over the molding process, material properties, and compatibility to create a strong bond between different materials. Understanding the foundation of this technology helps you optimize product design and manufacturing efficiency.

What Is Dual-Material Overmolding

Dual-material overmolding is a manufacturing process in which one material is molded over another, often combining plastics, rubber-like materials, or metals. This technique enhances product functionality by integrating features such as increased grip, durability, or aesthetics into a single component.

The process involves two distinct materials that are molded sequentially or simultaneously. You end up with a finished product combining both materials without the need for assembly. This reduces production time and potential weak points in the product.

Injection Molding Techniques

Injection molding forms the core of dual-material overmolding technology. You use specialized equipment that can inject two different materials, either one after the other or simultaneously, depending on the method. Standard techniques include two-shot injection molding and multi-shot molding.

Two-shot molding enables the production of parts with distinct layers or colors using a single machine and mold. This leads to improved precision and lower labor costs. The tooling must be designed to handle material transitions and temperature control to ensure proper bonding.

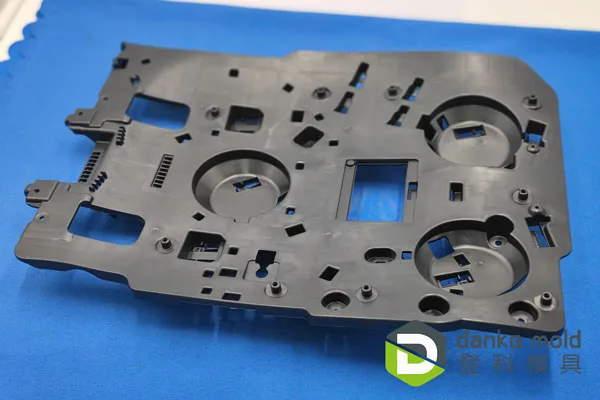

Injection molded parts

Material Compatibility and Selection

Material selection is critical for successful dual-material overmolding. You must ensure that the overmolding material bonds well with the substrate. Adhesion can be chemical, mechanical, or a combination of both.

Thermoplastics, such as TPEs (thermoplastic elastomers), are commonly paired with rigid plastic substrates to enhance flexibility or grip. Consider factors such as melting points, shrinkage rates, and chemical resistance when choosing materials.

|

Factor |

Importance in Dual-Material Overmolding |

| Chemical compatibility | Ensures strong bond and prevents delamination |

| Melting temperature | Must allow one material to mold over the othery |

| Shrinkage rates | Avoids warping or stress during cooling |

| Mechanical properties | Match for durability and performance |

You closely control these variables to achieve consistent results and a robust, high-quality finished product.

Applications and Advantages in Modern Product Design

Dual-material overmolding enhances product strength, usability, and aesthetics by combining multiple materials into a single, integrated unit. This process enables precise control over durability, grip, and protection, while meeting demanding production requirements.

Durable Consumer Electronics Casings

You can significantly improve the lifespan and resilience of consumer electronics by using dual-material overmolding for casings. Typically, rigid plastics like polycarbonate (PC) form the structural base, offering impact resistance and dimensional stability.

Soft-touch overmolded components, such as TPU (thermoplastic polyurethane) grips or seals, enhance ergonomics and user comfort. This combination also supports the encapsulation of waterproof electronics by creating tight seals, which is crucial for devices exposed to moisture.

By leveraging high-volume overmolding solutions, you benefit from faster production cycles and cost savings without sacrificing quality. These advantages make your product safer and more competitive in electronics markets.

Technological Advancements in Overmolding

Precision Bonding Techniques

- Chemical Bonding – Material compatibility optimization (PP + TPE)

- Mechanical Interlocking – Undercuts & textures for stronger adhesion

- Thermal Bonding – Controlled heating for optimal material fusion

Industry 4.0 Integration

- AI-Driven Process Control – Real-time adjustments for consistent quality

- Robotic Automation – High-speed, multi-material molding with minimal waste

- 3D-Printed Inserts – Hybrid manufacturing for complex geometries

Sustainable Overmolding

- Bio-Based TPEs – Renewable material alternatives

- Recyclable Material Pairs – Easier disassembly for circular economy

TPU-over-PC Injection Molding Use Cases

Injection molding with TPU over PC is particularly effective when you want flexibility on a rigid frame. TPU contributes elasticity, chemical resistance, and abrasion resistance, while PC provides strength and structural integrity.

This technique is well-suited for wearables, handheld devices, and automotive interior components, where soft-touch surfaces and durability are key. TPU-over-PC injection molding enables multi-colored designs and integrated shock absorption features.

Your designs can incorporate overmolded grip components to prevent slipping and improve handling. The careful balance of material properties ensures that your products remain functional under repeated stress and environmental exposure.

Shock-Resistant Device Housing Design

When designing shock-resistant housings, dual-material overmolding enables you to engineer layers that effectively absorb and dissipate impact energy. The hard outer shell shields internal components, while the softer overmold cushions shocks.

This design approach targets rugged electronics used in industrial or outdoor environments where drops and impacts are a common occurrence. Overmolded TPU elements enhance impact resistance and vibration damping, thereby extending device life.

Combining materials through injection molding streamlines assembly by integrating parts that are usually produced separately. It also reduces the risk of damage through improved adhesion between layers, ensuring reliable performance in harsh conditions.