When you need aerospace components with complex shapes and tight tolerances, 5-axis CNC machining offers a precise and efficient solution. This technology enables simultaneous movement across five axes, allowing you to create intricate parts in a single setup without the need for frequent repositioning. This reduces errors, saves time, and improves the overall quality of aerospace parts.

You will find 5-axis CNC machining especially valuable when working with challenging materials, such as titanium, aluminum, and aerospace-grade steels. Its ability to handle complex geometries enables the production of engine parts, turbine blades, and structural components that meet the demanding standards of the aerospace industry.

By using CNC machining with five axes, you gain flexibility in manufacturing custom and prototype aerospace parts with high accuracy. This ensures that your components can withstand extreme conditions while maintaining tight tolerances, making 5-axis machining a crucial tool in aerospace manufacturing.

Fundamentals of 5-Axis CNC Aerospace Components

Understanding the core aspects of 5-axis CNC aerospace components is crucial for producing complex, high-precision parts. Key factors include the definition and capabilities of 5-axis CNC machining, the requirements for machining precision aircraft parts, and the specific materials used, especially aerospace-grade aluminum.

What Are 5-Axis CNC Aerospace Components?

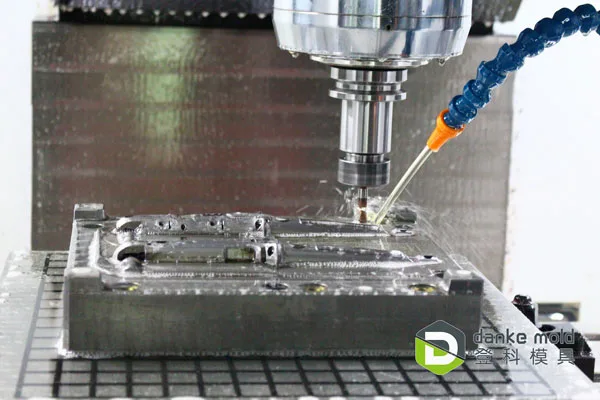

5-axis CNC aerospace components are parts manufactured using CNC machines that move cutting tools or workpieces along five different axes simultaneously. This enables the creation of complex shapes and geometries that single- or 3-axis machines cannot achieve.

Such components often include turbine blades, airframe structures, and satellite parts, where intricate details and tight tolerances are essential. The additional axes improve accessibility around the workpiece, reducing setup times and enabling continuous, high-precision machining.

You benefit from faster production cycles and better surface finishes. This technology supports the aerospace industry’s strict standards for quality and functionality by enabling advanced design implementation.

Precision Aircraft Part Machining Essentials

Precision in aircraft part machining means achieving extremely tight tolerances, often within microns. You must control tool paths accurately to meet safety and performance regulations specific to aerospace components.

5-axis CNC machining enables you to perform complex cuts in fewer setups, thereby reducing the risk of errors that cause dimensional inconsistencies. It also supports multi-tasking, such as drilling, milling, and contouring in a single run.

Maintaining a constant tool orientation improves surface quality and dimensional accuracy, which are crucial in parts such as engine components or structural elements. You need skilled operators and precise programming to leverage these capabilities fully.

Materials and Aerospace-Grade Aluminum Machining

Aerospace-grade aluminum alloys, such as 7075 and 6061, are commonly used in CNC machining due to their high strength-to-weight ratios and excellent corrosion resistance. You must adjust machining parameters, including feed rates and spindle speeds, to suit aluminum’s properties.

Unlike harder metals, aluminum allows higher machining speeds but demands attention to chip removal and heat control to prevent part distortion or finish defects. Tooling choices such as carbide or diamond-coated bits extend tool life when machining these alloys.

Understanding material behavior is crucial for producing parts that meet weight restrictions while maintaining their structural integrity. Proper material handling and CNC machining techniques ensure reliable performance in aerospace applications.

Advanced Machining Techniques and Solutions

Mastering aerospace component production requires precision, efficiency, and the ability to work with complex geometries. You will find that CNC machining techniques deliver high accuracy while addressing intricate design and material challenges essential for aerospace standards.

CNC machining services

5-Axis Milling for Flight Hardware

Using 5-axis milling for flight hardware allows you to machine complex parts in fewer setups, reducing errors and improving precision. The ability to move the cutting tool and workpiece along five different axes simultaneously lets you reach intricate angles and shapes.

This approach yields tighter tolerances, which are crucial for components such as brackets, structural parts, and mounts. Additionally, 5-axis CNC machining reduces cycle times and tool wear, optimizing your production efficiency. You achieve better surface finishes and consistent dimensional accuracy, which are key for flight safety and reliability.

Complex Turbine Blade CNC Machining

Turbine blades require precise contouring and the creation of exact cooling channels, tasks well-suited for CNC machining. Managing these complex shapes demands multi-axis controls to handle curves and tight radii without compromising blade integrity.

Your components benefit from advanced CNC programming that controls cutting paths to minimize vibration and thermal distortion. This control is necessary to maintain the blade’s aerodynamic efficiency and mechanical performance under extreme conditions. You can also integrate finishing processes to improve surface quality and extend component life.

Meeting High-Tolerance Aircraft Component Standards

Aerospace parts often demand tolerances within microns. CNC machining offers consistent repeatability, essential for meeting high standards, particularly in safety-critical elements such as engine mounts, landing gear parts, and control surfaces.

Your manufacturing process must incorporate strict quality controls, including in-process inspection and precision measuring tools. By combining high-speed CNC machines with multi-axis capabilities, you ensure components meet both dimensional and surface finish requirements outlined by aerospace regulations.

Aerospace CNC Machining Solutions

Choosing the right aerospace CNC machining solutions involves selecting advanced machinery and complementary processes, such as precision grinding and surface finishing, to ensure optimal performance. These solutions help you produce lightweight, durable parts that withstand the operational stresses of aviation environments.

Some providers offer integrated services, combining machining with post-processing steps such as deburring, anodizing, and plating to enhance corrosion resistance and durability. This full-service approach supports your need for reliable, ready-to-install aerospace components within tight production timelines.

For quotes on your aerospace CNC machining projects, visit dankemold.com to connect with experienced manufacturers.