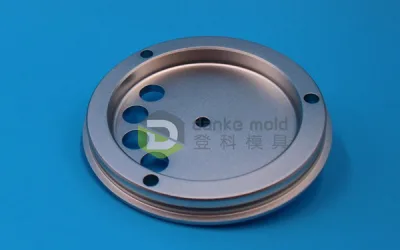

Danke Mold Blog

We would just like to share our rapid tooling, plastic injection molding and on-demand manufacturing ideas and experiences. Danke aims to provide you with a deeper understanding of the processes, best practices, and innovative approaches that have shaped our work in these fields.

The Importance of CNC Machining in Telecommunication Systems

In today's hyper-connected world, telecom systems form the backbone of global communication, data transfer and digital infrastructure. As these systems become more sophisticated, miniaturized and high-performance, the manufacturing processes...

Role of Plastic Injection Molding in Packaging Manufacturing

Plastic injection molding is a crucial manufacturing process widely used in the packaging industry to produce a diverse array of products with high accuracy, efficiency and cost-effectiveness. Its versatility makes it the preferred choice for...

Guide to Compression Molding: Methods, Materials, and Industry Uses

Compression molding is a foundational manufacturing process where a pre-measured polymer material is placed into a heated mold and formed under pressure. This is particularly crucial for creating strong, heat-resistant parts from materials that...

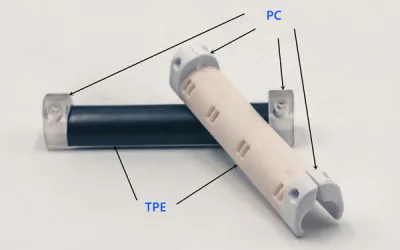

Overmolding in the Packaging Industry: Function, Form & User Experience

Overmolding in packaging transforms utilitarian containers into premium, functional, and user-friendly products. It's a key differentiator in competitive markets, adding tangible value through enhanced ergonomics, sealing, and brand perception....

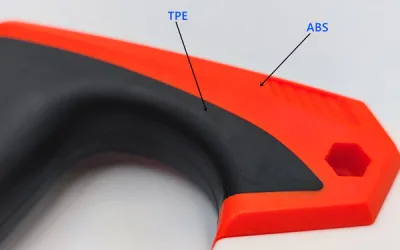

2-Shot Injection Molding in Automotive: Applications, Advantages, and Innovations

2-shot injection molding has evolved from a niche manufacturing technique to a cornerstone technology in the automotive industry. It enables the production of complex, multi-material components in a single, automated cycle, driving innovation in...

Compression Molding for Electrical Insulation: Manufacturing High-Performance Components

Compression molding is a fundamental and highly specialized manufacturing process for the production of high-performance electrical insulation components. These components are critical for safety, reliability and functionality across the electrical...

Lightweighting and Biodegradability: The Future of Packaging Plastic Injection Molding

The packaging industry is undergoing a major shift, fueled by an increased emphasis on sustainability, cost reduction and enhanced product functionality. Injection molding, renowned for its accuracy and ability to be produced at scale, plays a key...

Overmolding in Automotive Control Systems

Overmolding is absolutely critical in automotive control systems, where the fusion of rigid and soft materials directly impacts safety, functionality, durability and user experience. This application moves beyond simple comfort into the realm of...

The Critical Role of CNC Machining in Medical Parts Production: A Synthesis of Precision, Safety, and Innovation

In the highly regulated and life-dependent field of medical manufacturing, the choice of production technology is a critical determinant of success. CNC machining stands as a cornerstone process, offering an unparalleled combination of capabilities...

Vacuum Casting: Applications in Automotive Prototyping and Low-Volume Production

The ability to rapidly iterate designs and bring high-quality components to market more quickly is a critical advantage in the fast-paced and competitive automotive industry. Vacuum casting has emerged as the cornerstone technology to achieve this,...

How Plastic Injection Molding Shapes the Bodies of Modern Consumer Appliances

Look around any modern home - from the kitchen to the laundry room - and you are surrounded by sleek, seamless, durable appliance bodies made possible by plastic injection molding. This manufacturing process is the invisible force behind the form...

Rapid Tooling: A Guide to Principles, Benefits, and Applications

In today's fast-paced manufacturing landscape, the ability to move quickly from design to final product is a critical competitive advantage. Rapid Tooling has emerged as the cornerstone technology enabling this acceleration, bridging the gap...