Artificial intelligence is transforming plastic injection molding by improving precision, efficiency, and quality control in ways that were previously difficult to achieve. You can leverage AI to optimize machine settings, predict maintenance needs, and reduce defects, making your production process more cost-effective and reliable.

In plastic injection molding, minor adjustments can lead to significant changes in output. AI analyzes vast amounts of data from your machines and molds to identify patterns and recommend improvements faster than traditional methods.

By integrating AI, your operation can minimize downtime and waste while maintaining consistent product quality. This technology enables you to make informed decisions with real-time insights, ultimately enhancing the entire manufacturing workflow.

Fundamentals of AI in Plastic Injection Molding

You will find that AI optimizes processes, reduces defects, and improves productivity in plastic injection molding. It uses data-driven techniques to enhance decision-making and integrates seamlessly with modern manufacturing environments.

How AI Transforms Plastic Injection Molding

AI monitors real-time data from the molding machines to predict and prevent defects. You can reduce cycle times by adjusting parameters based on AI-generated insights. This results in higher-quality parts with fewer rejections.

AI systems automate process control, detect anomalies, and optimize material usage. For example, AI can predict when a mold requires maintenance, minimizing unexpected downtime. The automation also helps in fine-tuning temperature, pressure, and cooling time to improve yield.

Key Technologies: Machine Learning and Smart Factory Automation

Machine learning algorithms analyze patterns in your molding data to identify inefficiencies. These algorithms continuously learn from new data, adapting to variations in your plastic injection molding process.

Smart factory automation integrates AI with robotics and IoT sensors, enabling you to control molding machines and instantly adjust operations remotely. This automation supports seamless communication between devices and enhances overall equipment effectiveness (OEE).

You benefit from reduced manual intervention and better consistency. Both technologies work together to make your mold production more agile and responsive.

Integration With Industry 4.0 in Manufacturing

Industry 4.0 connects your plastic injection molding processes with digital networks for comprehensive monitoring and control. AI acts as the intelligence layer, interpreting large data sets from machines and sensors.

You gain real-time visibility into equipment status, quality metrics, and supply chain inputs. This connection supports predictive maintenance, just-in-time production, and energy optimization.

By embedding AI into your Industry 4.0 framework, you create a more flexible and efficient plastic manufacturing environment that can quickly adapt to changing demands.

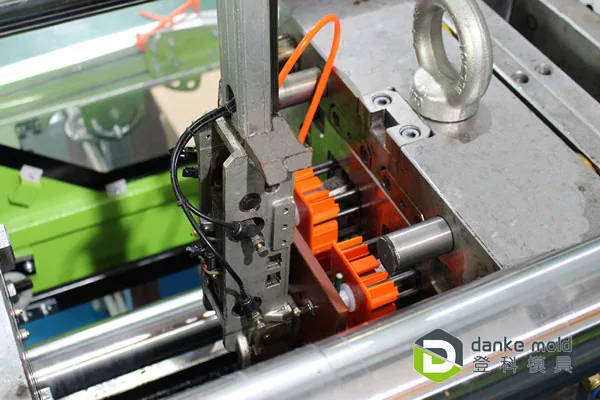

Plastic injection molding parts

AI Applications and Benefits in Plastic Injection Molding

AI enhances multiple aspects of plastic injection molding by improving quality control, predicting maintenance needs, and optimizing energy usage. These advances help reduce waste, lower downtime, and cut operational costs, directly impacting your manufacturing efficiency.

AI-Driven Quality Control and Defect Detection

AI-driven quality control in plastic injection molding utilizes machine vision and data analytics to detect defects in real-time. You can identify issues such as short shots, flashes, or warping early, preventing defective parts from progressing.

Automated inspection systems classify defects with higher accuracy than manual checks, reducing false rejects and improving yield. AI models learn from historical and live data, adapting to subtle process variations that affect quality.

Integrating AI-driven quality control ensures faster feedback loops and consistent product standards, which in turn lower your scrap rates and rework costs.

Predictive Maintenance and Process Optimization

Predictive maintenance in plastic molding relies on AI algorithms to analyze sensor data from machines. By forecasting equipment wear and failures before they occur, you avoid unexpected downtime and costly repairs.

You can schedule maintenance during planned stops rather than reacting to breakdowns. This proactive approach extends machine life and maintains steady production.

AI also optimizes molding parameters by automatically adjusting temperature, pressure, and cycle times. This improves cycle efficiency and reduces variability, saving you time and materials.

Enhancing Energy Efficiency With AI

Energy-efficient AI molding solutions monitor and control energy consumption throughout the plastic injection molding cycle. AI optimizes heating, cooling, and motor usage to match production needs precisely.

This approach reduces unnecessary power usage, lowering your energy bills and environmental impact. AI identifies patterns in energy waste and recommends changes to operator routines or equipment settings.

Incorporating AI-driven energy management enables you to meet sustainability goals without compromising output quality or speed.

Visit dankemold.com to obtain a quote for your plastic injection molding project.