Danke Mold Blog

We would just like to share our rapid tooling, plastic injection molding and on-demand manufacturing ideas and experiences. Danke aims to provide you with a deeper understanding of the processes, best practices, and innovative approaches that have shaped our work in these fields.

Vacuum Casting: The Bridge from Prototype to Production

The prototyping phase is a critical juncture in the race to bring a product to market. This is where ideas are physically validated, designs are tested, and stakeholders are convinced. While technologies such as 3D printing have revolutionized...

How to Optimize Your Compression Molding Process: A Comprehensive Guide

Compression molding is a highly versatile and efficient manufacturing process widely used in industries such as aerospace, automotive, electronics and consumer goods. It involves placing a pre-measured amount of a material - often a thermoset...

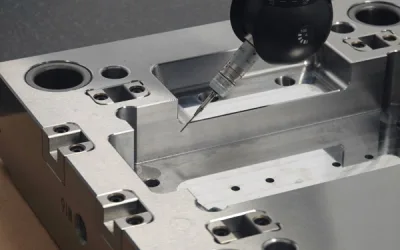

The Advantages of Using 5-Axis CNC in Rapid Prototyping

In the competitive arena of product development, speed, accuracy and flexibility are paramount. Rapid prototyping bridges the gap between digital design and physical reality, allowing engineers to validate, test and refine their ideas with...

Unlocking Value: The Key Benefits of Plastic Injection Molding

Plastic injection molding is a manufacturing process that has revolutionized the way industries produce a wide array of products. From everyday household items to complex automotive components, this technique offers unparalleled advantages, making...

The Five Most Common Plastic Resins for Plastic Injection Molding

Plastic injection molding is one of the most widely used manufacturing processes in the world of plastics. Its ability to produce complex, high-precision components at high volume makes it indispensable across a wide range of industries, from...

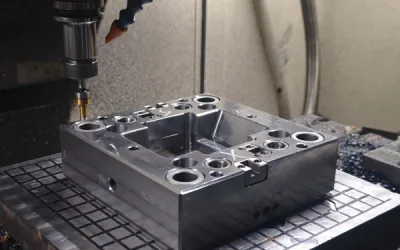

The Essential Guide to CNC Machining

CNC machining has revolutionized the manufacturing industry, providing precision, efficiency and versatility for the production of complex components across a wide range of industries. Whether you're an engineer, a product designer, or a...

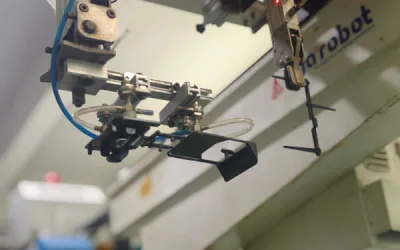

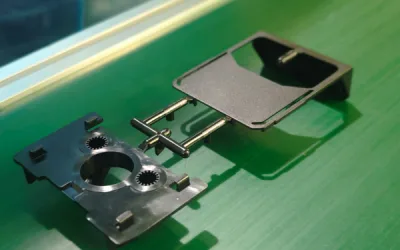

How Plastic Injection Molding Powers Modern Manufacturing

Few processes in the industrial production landscape are as synonymous with efficiency, scale and innovation as plastic injection molding. It has been the backbone of mass-produced plastic parts for decades, from the simplest bottle caps to...

The Strategic Advantage: Saving Time and Money with 3D Printing

For decades, 3D printing, also known as additive manufacturing, was perceived as a futuristic novelty - a tool for hobbyists and a costly fast prototyping machine for large corporations. Today, that perception has fundamentally shifted. 3D...

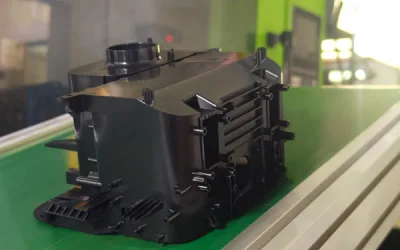

The Molded Brew: How Advanced Plastic Injection Molding Powers the Modern Coffee Maker

The morning ritual is nearly universal: the scoop of grounds, the pour of water, the press of a button, and the anticipatory gurgle leading to that first, essential cup. While coffee aficionados rightly focus on the origin, roast and grind size of...

Why Plastic Injection Molding is the Leading Choice for Mass Production

In the world of manufacturing, choosing the right production process is crucial to ensure efficiency, quality and cost-effectiveness. Of the various methods available, plastic injection molding has established itself as the dominant technique for...

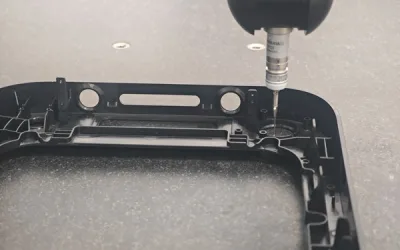

Enhancing Tool Performance: The Role of Overmolding in Screwdriver Handle Design

In the world of hand tools, performance is often measured at the point of contact: the sharpness of a blade, the hardness of a wrench jaw, or the precision of a screwdriver tip. Yet for the humble screwdriver, a tool defined by its ability to...

Plastic Injection Molding Reinvented: Embracing Speed, Sustainability and Digital Intelligence

Plastic injection molding has long been a cornerstone of manufacturing, especially in the production of complex plastic parts with high accuracy and efficiency. Over the decades, the industry has undergone a remarkable transformation, driven by...