Tooling & Plastic Injection Molding Services

Aluminum Tooling & Plastic Injection Molding

Steel Tooling & Plastic Injection Molding

Tooling & Plastic Injection Molding

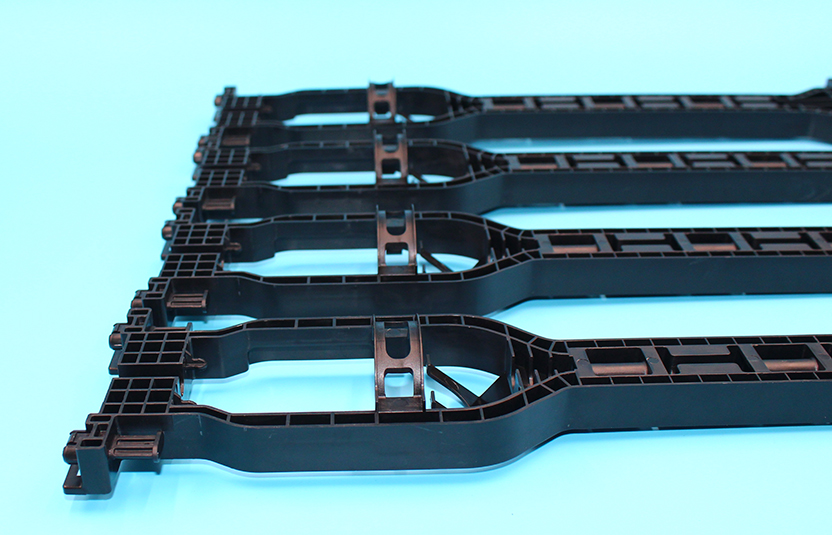

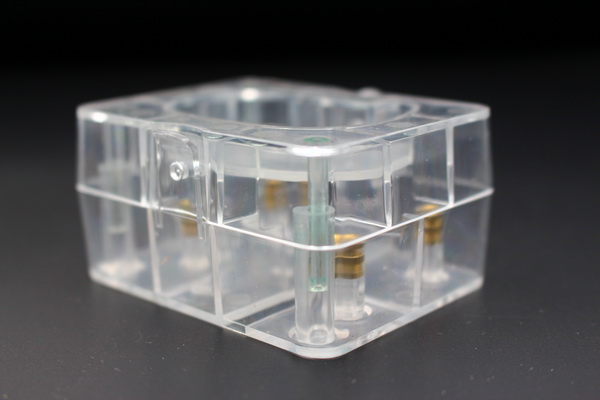

Danke helps you complete your custom plastic products into the market with our fast and dependable tooling & plastic injection molding service. It can meet all your low, medium, and high volume manufacturing demands. Multi-cavity tooling, over-molding and secondary post-molding operations are available for us. Our experienced team can make this last step in your process as quick as possible.

Plastic injection molding is a process that the pre-dried plastic pellets are fed into a heated barrel, mixed, and forced into a mold cavity, where it cools and hardens to the configuration of the cavity. Are you working on your next project? Just send our expert team your 3D file to get a free quote.

Our tooling & plastic injection molding services includes Aluminum Tooling & Plastic Injection Molding and Steel Tooling & Plastic Injection Molding.

Comparison of these two processes

| Process | Aluminum Tooling & Plastic Injection Molding | Steel Tooling & Plastic Injection Molding |

| Material | A variety of common plastics and engineering plastics or elastomer | A variety of common plastics and engineering plastics or elastomer, including abrasive or corrosive plastics |

| Available Size | 800×480×450mm depending on the part structure | 800×480×450mm depending on the part structure |

| Tolerance | DIN16901-1982 | DIN16901-1982 |

| Quantity | 50 to 10,000 + pcs | 50 to 500,000 + pcs |

| Drawing Format | STP, IGS, X_T | STP, IGS, X_T |

| Advantage | Fast turn-round | Tougher and more durable, more abrasive or corrosive plastics and more finish options available |