Steel Tooling &

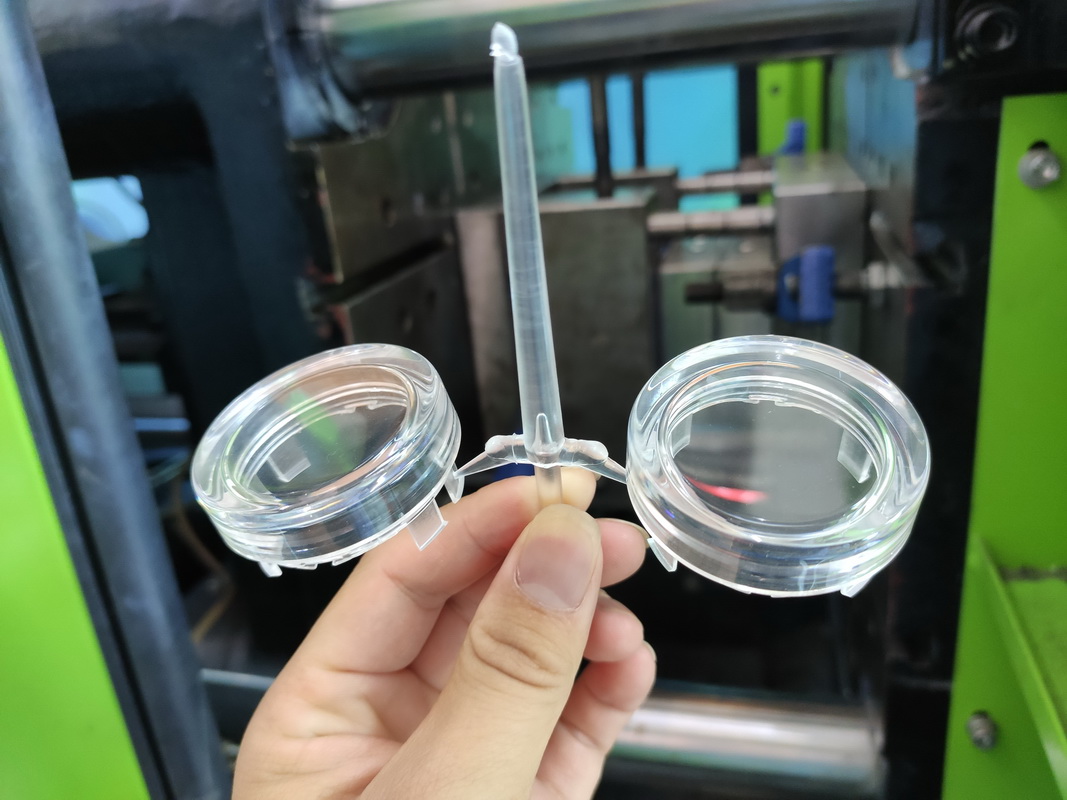

Plastic Injection Molding

From 50 to 500,000+ Parts

High Quality

Steel Tooling & Plastic Injection Molding Services

Danke offers competitive low cost, but consistently quality steel tooling & plastic injection molding service to help make your concept come true from 50 to 500,000+offs.

What is Steel Tooling & Plastic Injection Molding?

Steel tooling is to use P20, NAK80 or S136 as an interchangeable tool inserts, which are much tougher and more durable. The design of tooling structure and the possibility of using shared mold base will be according to the part structure and quantity demand. It can be flexibly used as rapid tooling or production tooling depending on the custom needs. More abrasive or corrosive plastics, and more finish options are available for steel tool.

A variety of common plastics and engineering plastics are available at Danke. Please read more in our resources.

Application of Steel Tooling & Plastic Injection Molded parts:

1 Molding material and tool design verification before building up mass production tool.

2 Proof-of-concept, including function verification, material verification & finish verification.

3 Over-molding with multi-materials.

4 Insert molding.

5 Low part cost production.

Contact our expert team for a free quote and to discuss your next steel tooling & plastic injection molding project.