There are Thermoplastic (ABS, PP, PC, Acrylic, POM, PVC, etc.) and Thermosetting Plastic (Polyester resin, Polyurethanes, Epoxy resin, phenol-formaldehyde resin, etc.) for most of plastic products. As a mold maker and plastic injection molding company, today we would like to share some knowledges about thermosetting plastic.

Thermosetting plastic is the polymer set solid after being melted to a liquid state by heating. This process of solidifying is known as curing. During curing all the small molecules are chemically linked together to form one giant network molecule. So they are distinguished, from the linear polymers (Thermosetting plastics) by being called network polymers.

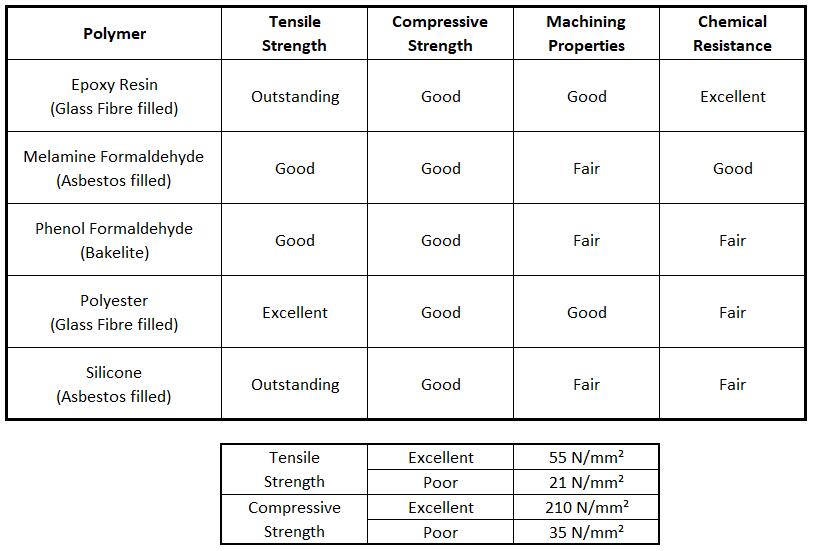

The change from the liquid state to solid is irreversible, and further heating results only in chemical breakdown, not melting. All the common thermosetting plastic are synthetic resins like epoxide, melamine, phenol, polyester for example, which in the hard state are invariably glassy and brittle in nature. Their structure is based on carbon like the linear polymers. The silicones, however, are another family of material whose structure is based upon silicone, not carbon,. They are usually grouped with the common thermosetting plastic, the properties of some of which are given below in the table shown. It will be noticed that fillers are commonly used either to improve or modify the mechanical or chemical properties of the resin, or in order to give cheaper material.

Thermosetting plastics are processed to their final shape by molding. This may be followed in some instances by machining. We will consider each of these process in turn.

Advantages of thermosetting Plastic

Advantages of thermosetting Plastic

1) Durable with high temperature performance

2) Thick to thin wall capabilities

3) Greater dimensional stability

4) Cost effective

Disadvantages of thermosetting Plastics

1) Unable to be recycled

2) More difficult to obtain good surface finis

3) Can’t be remolded or reshaped

Molding of thermosetting plastic.

Injection molding is the most important process for both thermoplastics and thermosetting plastics, however, there are several kinds of other processes available for thermosetting plastic as well, they are:

1) Compression molding

2) Open flash molding

3) Transfer molding.

The latter two process are not very frequently-used, and since we have been very familiar with injection molding, so here we focus on the compression molding.

This is a traditional molding method which has been used in the plastics industry for many years. The process is superficially similar to the hot pressing of metals in so far that the plastic is placed into a heated mold on a vertical press and subjected to pressure. The main difference is that a thermosetting plastic is molded at a melting temperature where as a metal is hot pressed at sintering temperature. The plastic is held in the mold from the liquid state until the curing stage is over when polymerization is complete. It should be noticed that compression molding would be impracticable for thermoplastics which have no curing stage during which a chemical reaction take place; because the mold would require cooling each cycle in order to allow the component to harden sufficiently for extraction.

The process cycle time obviously depends upon the during time, and with modern plastics this has been considerably shortened. Vertical hydraulic presses are usually used up t0 0-5MN capacity having an upstroke or downstroke action. Pressure applied to the plastic in the mold is to the order of 15 N/mm², and the curing temperature is to the order of 200° C, Mold heating can be successfully accomplished using steam, gas or electric resistance heating.