Injection mold making has been one of the crucial phases in any manufacturing industry. This will include making high-quality, precision parts used in a wide range of applications. The plastic molding maker ideally requires a host of important elements that include skilled professionals, advanced machinery, and modern technology.

How has technology impacted modern injection mold making? It may be a little practical to check out the prime technological advancements in the realm of mold making.

Computer aided software

One of the most essential technological advancements has been in the use of computer aided software in the mold making. This technology has been able to help you in the creation of 3D models which assists you in checking through simulation and find how the product performs if manufactured. It acts as a sort of prototype before taking up the final productions.

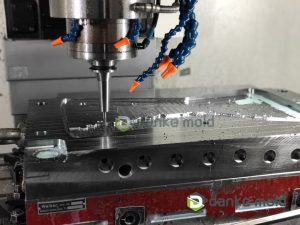

High speed machining

Yet another technological advancement that you would notice being used by the Injection Mold Maker is the high speed machining. This assists the makers be capable of making high quality molds in generally lesser time. This technology has also enhanced the accuracy and precision in the mold making. The possibility of errors has been considerably reduced and there is an overall increase in the quality of the final product.

Artificial intelligence

The use of AI or artificial intelligence is yet another new advancement in the field of mold making. AI can help you analyse the data and thus identify any potential data or design flaws in the mold making. You can also use the technology in helping you optimise the manufacturing process. This helps in reducing the waste and helping in improving the efficiency.

A better quality control

The technology has also been lending a helping hand in an effective quality control in mold making. The use of sophisticated sensors and monitoring systems has been instrumental in making the molds that exactly meet the requisite specifications.

3D Printing

The concept of 3D printing has been yet another milestone that has been helping the injection mold making or plastic mold making in a variety of ways. The 3D mold making has been helpful and instrumental in helping the mold makers create a physical mold without hassles. This technology can be a great asset in letting you reduce the time and efforts needed for traditional mold making. The 3D printing has become a practical solution in letting you achieve a faster prototyping. This can help the mold makers making the necessary changes before hitting the final production phase.

Technology has revolutionised several fields, and injection mold making is not an excuse either. The advanced technologies such as 3D printing, CAD and AI capabilities have become quite instrumental in helping achieve a better degree of workmanship in mold making. As the technology goes ahead in the days to come, we can expect a host of such path breaking achievements and developments helping us achieve better results. Let us wait for that to happen and when it does, it will indeed be something a dream comes true for the tech driven!