Danke Mold Blog

We would just like to share our rapid tooling, plastic injection molding and on-demand manufacturing ideas and experiences. Danke aims to provide you with a deeper understanding of the processes, best practices, and innovative approaches that have shaped our work in these fields.

2-Shot Injection Molding in Consumer Electronics: Enabling Design, Durability, and Ergonomics

In the highly competitive consumer electronics market, 2-Shot Injection Molding is a critical manufacturing process that allows brands to create products with superior aesthetics, enhanced user experience and robust functionality. This is the...

Overmolding: A Comprehensive Guide to the Process, Benefits, and Applications

In many industries, products often require distinct core and surface characteristics - something that a single material alone cannot provide. To meet this demand, manufacturers employ a technique called over-molding, in which one material is...

Unlocking the Potential of Insert Molding: Key Industries and Applications

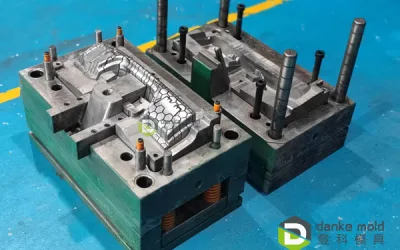

What is Insert Molding? Insert molding is a specialized injection molding process where a pre-formed component (the "insert") is placed into a mold cavity. The molten plastic is then injected into the mold, where it flows around, over, or through...

Plastic Injection Molding in the Automotive Industry: Processes, Benefits, Applications, and Future Trends

Plastic injection molding has become an indispensable manufacturing process in the automotive industry, revolutionizing how vehicles are designed, built and executed. This technology enables the production of high-quality, durable, complex...

Why Pressure Die Casting Prevails in Electronics Manufacturing

In electronics manufacturing, Pressure die casting is the process of choice because it produces robust, lightweight components with exceptional accuracy. This capability is critical for creating intricate frames and housing that provide critical...

From Blueprint to Bin: The Unsung Engineering in Your Desktop Rubbish Bin

Have you ever stopped to look at the humble desktop rubbish bin on your desk? It seems simple enough—a small container to hold scraps. But have you considered its perfect round shape, the smooth, glossy finish, the seamless way the lid fits, or the...

Top 10 Plastics for Injection Molding: Properties and Applications

Selecting the right plastic is fundamental to the success of any injection-molded part. This guide provides a detailed overview of the most widely used plastic injection molding materials, helping you make an informed choice for your next project....

The Strategic Advantages of Vacuum Casting in Medical Device Development

In the medical industry, the development of new products requires exceptional accuracy, compatibility with medical grade materials, and fast turnaround times. Therefore, a solution that satisfies these requirements is essential. Vacuum casting...

Understanding 2-shot injection molding: advantages, processes, and key comparisons with overmolding

In the realm of modern manufacturing, plastic injection molding continues to evolve, offering innovative techniques to efficiently produce complex, high-performance parts. Among these advanced methods, 2-shot injection molding – also known as...

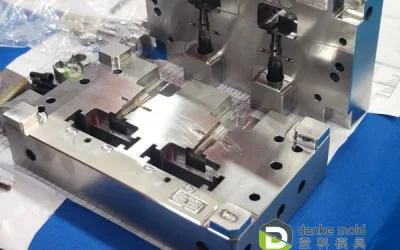

Rapid Tooling: The Bridge to Faster, Smarter Production

In today's highly competitive manufacturing landscape, the ability to produce high-quality products quickly and efficiently is critical. Traditional methods of tooling, while reliable, often involve lengthy lead times and high costs, which can...

Strategic Manufacturing: Leveraging Low-Volume Manufacturing for Market Specialization

In an era dominated by global mass manufacturing, competitive advantage is increasingly found not in size but in specialization. For innovators, startups, and established companies targeting niche applications, low-volume manufacturing (LVM) has...

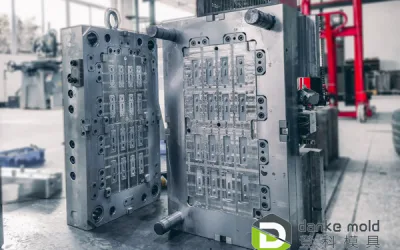

Implementing Automation Systems in High Volume Manufacturing for Maximum Productivity

High-volume manufacturing demands sophisticated infrastructure supporting continuous production operations. You need substantial investment in equipment, facilities, and automation systems. These operations prioritize speed, consistency, and...