Rapid Prototyping Services

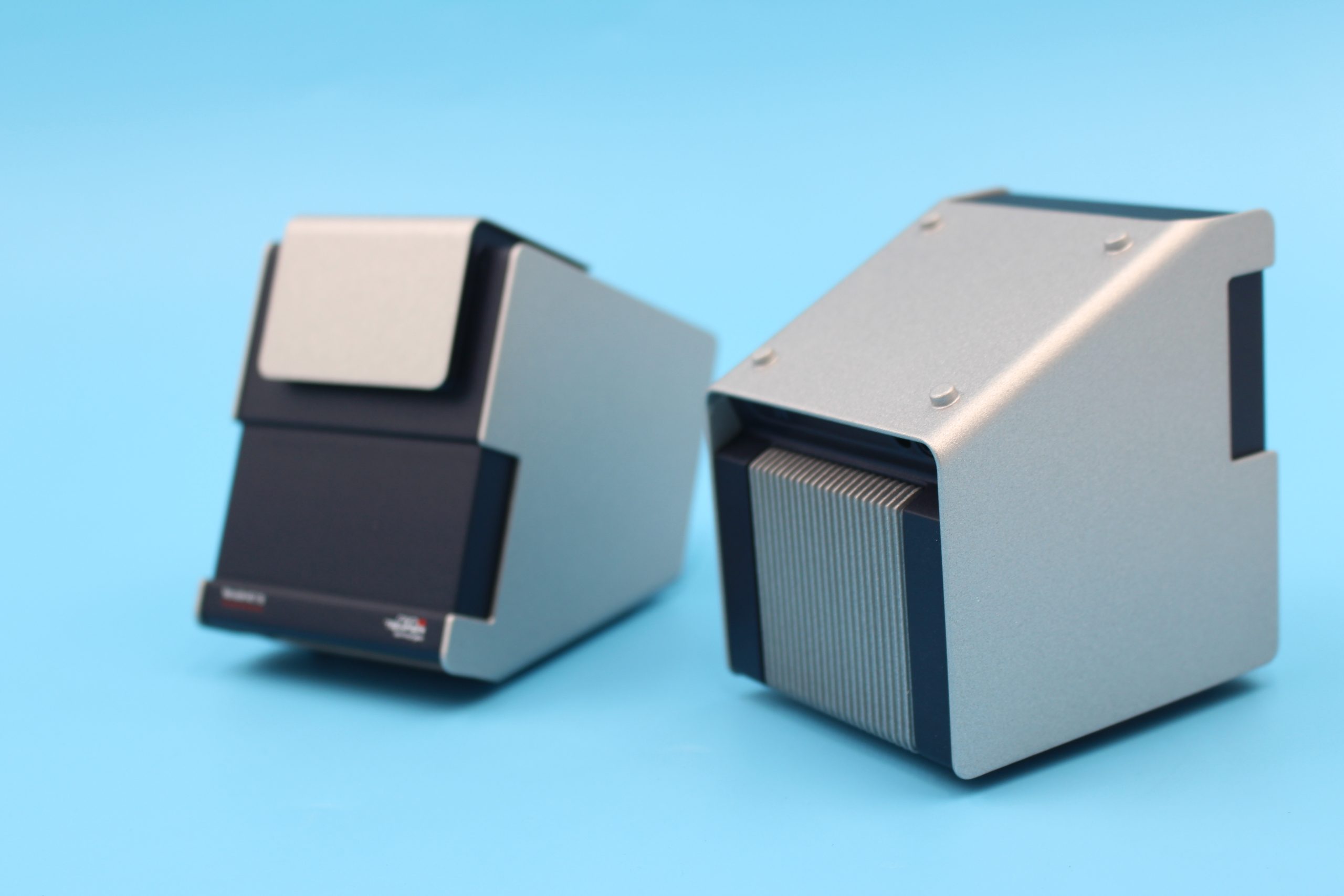

- CNC Machining

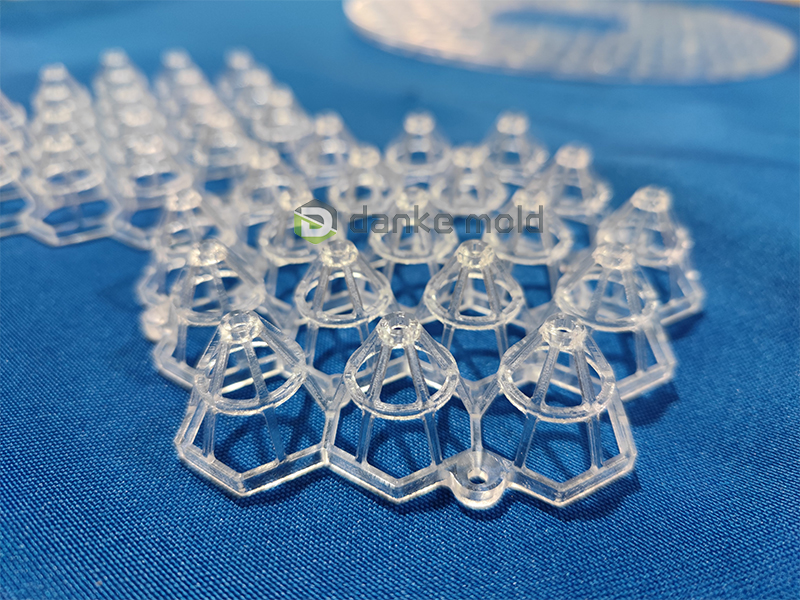

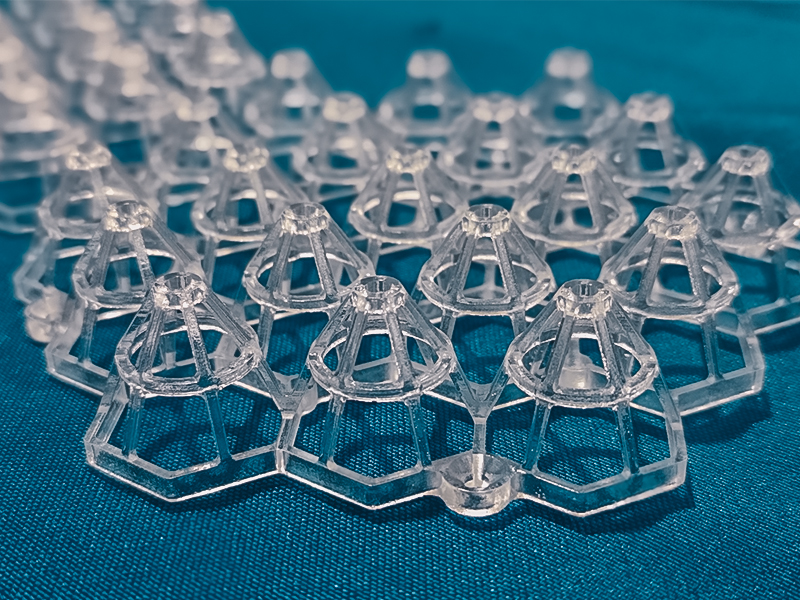

- SLA(Stereolithography)

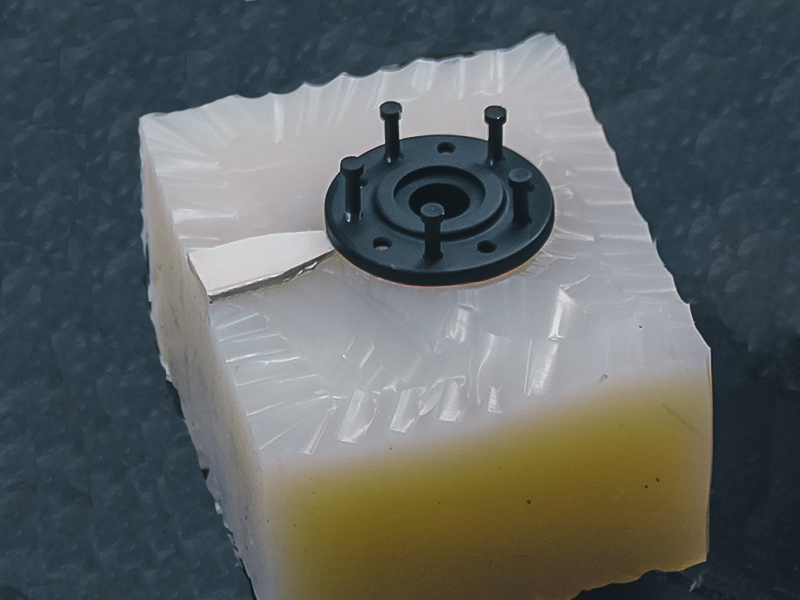

- Vacuum Casting

- Sheet Metal Forming

Rapid Prototyping

Danke helps you evaluate and develop your new products quickly, economically and with less risk. Successful product development means developing a product of high quality, in a short time and at a reasonable cost. The development of the part and its introduction to market is a time consuming process. We deeply know speed matters, and therefore, we always devote ourselves to offering better and faster prototypes to help with your product development. Are you working on your next project? Just send our expert team your 3D file to get a free quote.

3D Printing

- SLA, SLS, DMLS For Metal/Plastic Parts

- Multiple Material & Surface Finishes

- Cost Effective & Fast Turnaround

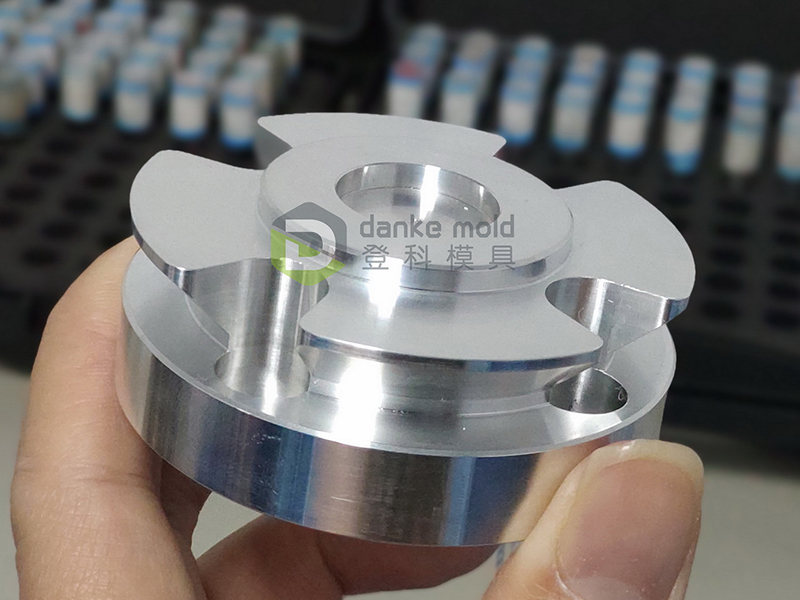

CNC Machining

- High Precise & High Speed

- Various of Matal & Plastic Material

- Various of Surface Finishes Available

Comparison of these three processes

| Process | SLA | CNC Machining | Vacuum Casting |

| Material | Somos 14120 (ABS) | A wide range of plastic and metal materials | Typical plastic & rubber |

| Available Size | 500×500×400mm | 1000×600×500mm | 700×500×400mm |

| Tolerance | +/-0.1mm | DIN-2768-1-fine for metal DIN-2768-1-medium for plastics |

DIN-2768-1-medium |

| Quantity | 1 to 10 pcs | 1 to 500+ pcs | 1 to 100+ pcs |

| Drawing Format | STP, STL, IGS, X_T | STP, IGS, X_T | STP, IGS, X_T |

| Advantage | Low cost, fast turnaround, no need sectioning |

Precise, more available material, visible | Cost effective, fast turnaround |